-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Aug . 10, 2025 04:40 Back to list

Efficient Cable Pulling Tools & Heavy Duty Rollers

The Critical Role of Cable Pulling Tools in Modern Infrastructure Development

In the rapidly evolving landscape of global infrastructure, the efficient and safe deployment of extensive cable networks is paramount, ranging from power transmission and telecommunications to industrial automation and data centers. This intricate process relies heavily on specialized equipment, specifically high-performance cable pulling tools. These indispensable devices are engineered to navigate the complexities of long distances, challenging conduits, and heavy cable loads, ensuring seamless installation while minimizing risks to both personnel and the cabling itself. The global market for these tools is experiencing robust growth, driven by massive investments in smart grids, 5G networks, renewable energy projects, and urban development. According to a recent industry analysis by Grand View Research, the global cable accessory market, which encompasses pulling tools, was valued at USD 52.8 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 6.2% from 2023 to 2030, underscoring the escalating demand for reliable and efficient cable installation solutions. Key industry trends indicate a strong shift towards automation, enhanced safety features, and tools designed for increasingly larger and heavier cables, often made from specialized materials that require precise handling. Furthermore, the emphasis on sustainability and energy efficiency in construction and infrastructure projects is influencing the design and material selection for these tools, pushing manufacturers to innovate with lightweight yet robust composites and advanced power systems that reduce operational energy consumption. The inherent challenges in cable installation, such as friction management, avoiding cable damage, ensuring worker safety in confined spaces or at heights, and maintaining installation speed, necessitate tools that offer superior mechanical strength, ergonomic design, and intelligent control systems. This comprehensive overview will delve into the technical intricacies, application diversity, manufacturing excellence, and strategic advantages offered by advanced cable pulling tools, providing B2B decision-makers with the insights necessary to optimize their infrastructure projects and secure a competitive edge in a demanding market.

Understanding Cable Pulling Tools: A Deep Dive into Technology and Application

The umbrella term "cable pulling tools" encompasses a diverse range of equipment, each designed for specific stages and challenges of cable installation. At its core, the objective is to guide cables through conduits, trays, or open trenches with minimal friction and maximum control. Central to this suite of tools are specialized devices like the Cable Puller and Fish Tape, which represent the foundational elements for guiding cables. A Cable Puller, often referred to as a power puller or winch, is an electromechanical or hydraulic device designed to exert significant pulling force, typically ranging from a few hundred pounds to several tons, making it indispensable for installing heavy or long runs of cable. It consists of a motor, a drum or capstan, and a control system, allowing operators to manage the pulling speed and tension precisely, preventing over-stressing the cable. The force is transmitted to the cable via a pulling rope or tape, often made of high-strength synthetic fibers like Dyneema or steel wire, which is attached to a pulling grip on the cable end. In contrast, a Fish Tape is a more manual, flexible tool, usually made of spring steel, fiberglass, or composite materials, used for pulling smaller wires or pilot lines through narrow conduits or wall cavities. Its key characteristic is its flexibility combined with rigidity to push through obstacles, making it ideal for residential, commercial, and light industrial applications where a power puller might be overkill. Related equipment, such as a cable pulling winch, often refers to the powered variants of the cable puller, emphasizing its mechanical advantage. Cable tray rollers, also known as cable rollers or cable guides, are crucial accessories used to support and guide cables over obstacles, around bends, and along the ground during installation, significantly reducing friction and preventing abrasion. These rollers are typically constructed from robust materials like aluminum, steel, or high-density polymers, ensuring durability and smooth operation under heavy loads. Heavy duty cable rollers are specifically engineered for larger, heavier power cables in utility, industrial, and infrastructure projects, featuring reinforced frames, larger diameter wheels, and enhanced load-bearing capacities. Lastly, cable pulling rollers are a general category referring to all types of rollers designed to facilitate the pulling process, including corner rollers, straight rollers, and specialized duct rollers. The symbiotic use of these tools ensures a streamlined, safe, and efficient cable installation process, mitigating potential damage to valuable cabling infrastructure and optimizing project timelines.

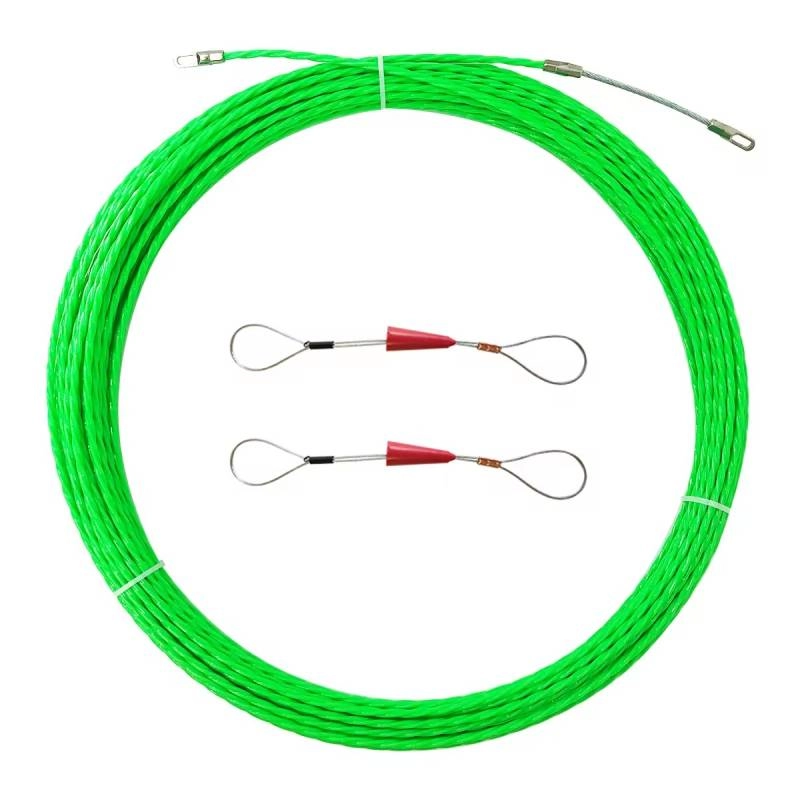

Image 1: Illustrative application of cable pulling tools in a demanding industrial environment.

The Manufacturing Process: Ensuring Precision and Durability

The manufacturing of high-quality cable pulling tools is a complex process demanding precision engineering, robust material selection, and stringent quality control, ensuring that the final product can withstand the demanding conditions of infrastructure projects. This process typically begins with the selection of premium raw materials, such as high-strength alloy steels for structural components, aerospace-grade aluminum for lightweight frames, and specialized polymers for rollers and protective coatings. For load-bearing parts like shafts and gear components in a cable pulling winch, advanced metallurgical processes such as forging and precision casting are employed to create blanks with superior grain structure and mechanical properties, enhancing tensile strength and fatigue resistance. These blanks then undergo meticulous CNC (Computer Numerical Control) machining, which allows for ultra-precise shaping, drilling, and finishing, ensuring exact dimensional tolerances and smooth surfaces that are critical for optimal performance and extended lifespan. For components like cable tray rollers and heavy duty cable rollers, the manufacturing process emphasizes not only material strength but also surface finish and bearing quality. Roller wheels might be crafted from hardened steel or high-density polyurethane (HDPU), which offers excellent wear resistance, low friction, and non-marring properties, protecting the cable jacket. The bearings themselves are often sealed, precision-machined units, rated for heavy loads and high duty cycles, sometimes incorporating self-lubricating features to reduce maintenance. Beyond primary shaping, secondary processes such as heat treatment (e.g., induction hardening, tempering) are applied to critical components to enhance their hardness, toughness, and wear resistance, especially for gear teeth and bearing surfaces. Surface treatments, including powder coating, galvanization, or anodization, are then applied to provide superior corrosion resistance, critical for tools exposed to harsh outdoor environments, moisture, and various industrial chemicals, thus extending the tool's lifespan significantly. Throughout the entire manufacturing pipeline, rigorous testing protocols are implemented. This includes material composition analysis using spectrometry, dimensional checks with CMM (Coordinate Measuring Machine) systems, non-destructive testing (NDT) such as ultrasonic or magnetic particle inspection for internal flaws, and dynamic load testing to simulate real-world operational stresses. Adherence to international standards like ISO 9001 for quality management, ANSI (American National Standards Institute) standards for performance and safety, and specific European CE marking requirements for machinery ensures that each tool meets or exceeds global benchmarks for reliability and safety. The typical design life of well-maintained professional cable pulling tools ranges from 10 to 20 years, depending on usage intensity and preventative maintenance. These robust manufacturing standards make such tools indispensable in industries requiring high reliability and safety, including petrochemicals (for laying power and control cables in hazardous areas, benefitting from anti-corrosion features), metallurgy (handling heavy-duty cables for furnaces and rolling mills, where robust rollers reduce friction), and water supply/drainage (installing critical power lines for pumping stations, where energy-efficient tools minimize operational costs). The focus on durability, precision, and application-specific material selection ensures that these tools not only perform effectively but also contribute to long-term operational savings and enhanced safety across diverse industrial applications.

Image 2: A powerful cable pulling winch designed for heavy-duty applications.

Technical Parameters and Performance Metrics of Advanced Cable Pulling Tools

The performance of cable pulling tools is quantifiably defined by a range of critical technical parameters that directly impact their efficiency, safety, and suitability for various applications. Understanding these specifications is essential for B2B professionals to select the optimal equipment for their projects. For a cable pulling winch or powered puller, primary parameters include its maximum pulling capacity (measured in kN or lbs), which indicates the maximum force it can exert; typical capacities range from 10 kN (2,200 lbs) for lighter tasks to over 100 kN (22,000 lbs) for heavy power cables. Another crucial metric is the pulling speed, often adjustable, measured in meters per minute (m/min) or feet per minute (ft/min), which dictates the pace of installation and influences project timelines. For instance, a variable speed control from 0.5 m/min to 15 m/min allows precise handling of different cable types and conduit conditions. The motor type and power (e.g., 2.2 kW electric, 9 HP hydraulic) also define the tool's capabilities and power requirements. For Fish Tapes, key specifications include their length (e.g., 30m, 60m, or 100ft, 200ft), diameter (e.g., 4mm, 6mm), and material composition (fiberglass, steel, composite), which dictate their flexibility, rigidity, and resistance to kinking. For cable tray rollers and heavy duty cable rollers, crucial parameters include their load-bearing capacity per roller (e.g., 500 kg to 2000 kg), roller material (e.g., aluminum, steel, HDPU), wheel diameter, and the type of bearing used (e.g., sealed ball bearings, plain bearings), which collectively determine their friction reduction capabilities and durability under heavy loads. The design of the roller frame, whether straight, corner, or specialized for duct entry, also impacts its functionality, with corner rollers typically featuring multiple, angled wheels to guide cables smoothly through turns, significantly reducing side wall pressure. The coefficient of friction, though not always directly specified, is a performance indicator; lower friction means less pulling force required, translating to reduced cable stress and energy consumption. Modern tools often integrate advanced features such as electronic tension monitoring systems, which provide real-time feedback on pulling force, preventing over-tensioning and potential cable damage. Data logging capabilities allow for post-installation analysis, crucial for quality assurance and compliance. Portability (weight and dimensions) and ease of setup are practical parameters influencing operational efficiency, especially in complex job sites. Environmental ratings (IP standards for dust and water ingress) are vital for outdoor or harsh industrial environments. Considering these detailed technical parameters, a comparative analysis of different models or manufacturers becomes highly effective for procurement teams, ensuring that the selected cable pulling tools not only meet current project demands but also offer long-term reliability and cost-effectiveness.

Image 3: Cable tray rollers strategically placed to minimize friction during installation.

Comparative Analysis of Key Specifications (Illustrative Data)

Diverse Application Scenarios Across Industrial Sectors

The versatility and necessity of cable pulling tools extend across a multitude of industrial and commercial sectors, each presenting unique challenges that these specialized devices are designed to overcome. In the energy sector, particularly for renewable energy projects, the installation of high-voltage transmission lines for solar farms and wind turbines demands powerful cable pulling winch systems capable of handling extreme lengths and weights of power cables over varied terrains. Here, the emphasis is on minimizing downtime and ensuring the integrity of the insulation during installation, where precise tension control and smooth guidance provided by advanced cable pulling rollers are paramount. For urban infrastructure development, including underground utility installations for new residential or commercial districts, heavy duty cable rollers are indispensable for navigating cables through dense networks of existing conduits and around tight bends, preventing damage to both the cables and the surrounding structures. In the telecommunications industry, specifically with the global rollout of 5G networks and fiber optic broadband, the rapid deployment of sensitive fiber optic cables requires tools like composite Fish Tapes for delicate, long-distance pulls through congested conduits, alongside lightweight cable tray rollers for efficient routing within data centers and communication hubs. The manufacturing sector, from automotive plants to heavy machinery factories, continuously expands its automated production lines, necessitating the installation and upgrade of vast networks of control and power cables. Here, cable pulling tools facilitate quick and safe installation, minimizing disruptions to production schedules. The petrochemical industry, characterized by explosive atmospheres and corrosive environments, relies on specialized cable pulling tools designed with intrinsically safe components and corrosion-resistant coatings, ensuring the integrity of electrical systems that power critical processes and safety mechanisms. In large-scale construction projects, whether erecting skyscrapers or building expansive industrial complexes, these tools are essential for vertical and horizontal cable runs, ensuring that electrical, data, and communication cables are installed efficiently and safely, often under strict deadlines. The marine and offshore industry utilizes robust cable pulling tools for laying subsea cables for power and data transmission, where extreme depths and harsh environments necessitate equipment with exceptional durability and reliability. Even in sectors like water supply and drainage, where power cables are vital for pumps and control systems, the ability to rapidly and safely install cables in damp or corrosive underground environments is crucial. The collective benefits across these sectors include significantly reduced installation times, enhanced worker safety by minimizing manual handling of heavy cables, protection of valuable cable assets from abrasion or excessive tension, and ultimately, a substantial reduction in overall project costs. The adaptability of these tools, from small-scale residential wiring using flexible Fish Tapes to massive power line installations requiring multi-ton cable pulling winches, underscores their universal importance in modern industrial operations.

Image 4: Robust heavy duty cable rollers facilitating the installation of large power cables.

Technological Advantages and Innovations in Cable Management

The continuous advancement in the design and engineering of cable pulling tools brings forth significant technological advantages, directly contributing to enhanced operational efficiency, reduced costs, and improved safety across all installation projects. One prominent advantage lies in superior friction management. Modern cable tray rollers and cable pulling rollers are engineered with low-friction materials like UHMW-PE (Ultra High Molecular Weight Polyethylene) or precision-machined, self-lubricating bearings that dramatically reduce the coefficient of friction between the cable and the guide surface. This reduction in friction translates directly into lower pulling forces required from the cable pulling winch, thereby minimizing the stress on the cable and reducing the risk of insulation damage, stretching, or kinking. Less required force also means lower energy consumption for powered pulling equipment, leading to substantial operational savings and aligning with global initiatives for energy efficiency. Furthermore, the integration of intelligent control systems, such as real-time digital tension readouts and automated shut-off mechanisms in advanced cable pulling tools, represents a significant leap forward in preventing over-tensioning, which is a primary cause of cable failure during installation. These systems provide operators with precise feedback, allowing for immediate adjustments and ensuring the cable's integrity throughout the pull, particularly critical for expensive, high-voltage, or fiber optic cables. Another crucial advantage is enhanced corrosion resistance. Tools designed for outdoor use or harsh industrial environments, such as those in the petrochemical or marine sectors, often feature specialized coatings like hot-dip galvanization, zinc plating, or advanced powder coats, alongside the use of stainless steel or marine-grade aluminum components. This robust protection against rust and chemical degradation significantly extends the lifespan of the equipment, reduces maintenance frequency, and ensures reliable performance in corrosive atmospheres, contributing to a lower total cost of ownership. Ergonomic design and modularity also play a vital role; many cable pulling tools are now designed for rapid assembly and disassembly, ease of transport, and compatibility with various pulling setups, optimizing site logistics and reducing manual labor efforts. The use of lightweight yet high-strength materials, such as aerospace-grade aluminum alloys and advanced composites, ensures that tools like heavy duty cable rollers can withstand immense loads without being excessively cumbersome, improving maneuverability and reducing worker fatigue. These innovations not only accelerate installation timelines but also foster a safer working environment by reducing physical strain on technicians and minimizing potential hazards associated with handling heavy cables and equipment. The cumulative effect of these technological advancements is a more precise, efficient, and reliable cable installation process that meets the stringent demands of modern infrastructure development while delivering measurable economic and safety benefits.

Choosing the Right Partner: Manufacturer Comparison and Customization

Selecting the appropriate manufacturer for cable pulling tools is a strategic decision for B2B enterprises, directly impacting project success, operational efficiency, and long-term cost-effectiveness. The market features numerous manufacturers, each with varying strengths in terms of product range, technological innovation, customer support, and adherence to international standards. When evaluating potential partners, key considerations should include the manufacturer's proven track record and reputation within the industry, reflected by years of service, comprehensive project portfolios, and positive client testimonials. A manufacturer's commitment to research and development is crucial, indicating their ability to integrate the latest technologies, such as IoT-enabled tension monitoring or advanced material science, into their cable pulling tools. Certifications play a pivotal role in establishing credibility; look for manufacturers who hold ISO 9001:2015 for quality management, demonstrating consistent product quality, and adherence to specific safety standards like OSHA or CE marking, ensuring compliance with regional regulations. Furthermore, the breadth and depth of their product catalog are important – do they offer a comprehensive range of cable pulling winch systems, a variety of cable tray rollers and heavy duty cable rollers, and specialized Fish Tapes? This indicates their capability to address diverse project requirements. Beyond standard offerings, the ability to provide customized solutions is a significant differentiator. Many infrastructure projects encounter unique challenges – unusual conduit configurations, extremely long pulls, or specialized cable types – that standard tools cannot fully address. A manufacturer capable of offering bespoke engineering, from designing custom-sized cable pulling rollers to developing a specialized cable pulling winch with tailored pulling capacities or precise control algorithms, can provide a distinct competitive advantage. This might involve adapting existing designs or developing entirely new solutions based on client specifications, often requiring close collaboration between the client's engineering team and the manufacturer's R&D department. Such customization ensures optimal tool performance for specific, complex applications, preventing costly delays or cable damage. Moreover, evaluating a manufacturer's global supply chain and after-sales support network, including parts availability, technical assistance, and training programs, is critical for minimizing downtime and ensuring the longevity of the investment. A reliable partner will offer robust warranties and responsive customer service, reflecting their confidence in product quality and their commitment to client satisfaction. For instance, Bilopowtel stands out with its dedication to high-quality manufacturing, adherence to international standards, and a strong emphasis on providing solutions tailored to specific industrial needs, as evidenced by their comprehensive product range and client-centric approach, ensuring that their cable pulling tools are not just products but integral components of a successful project strategy.

Image 5: An example of a customized cable pulling tool engineered for specific project requirements.

Real-World Application Cases and Success Stories

The tangible benefits of employing advanced cable pulling tools are best illustrated through real-world application cases, showcasing how these specialized devices contribute to successful project outcomes across various complex scenarios. One notable instance involved a major urban power grid upgrade in a densely populated metropolitan area. The project necessitated the underground installation of 132kV high-voltage power cables spanning over 15 kilometers, navigating through existing utility conduits and under busy intersections. The primary challenge was to minimize disruption while ensuring precise cable tension to prevent damage to the costly XLPE insulated cables. By deploying a high-capacity cable pulling winch equipped with real-time digital tension monitoring, along with an array of specialized cable tray rollers and corner rollers, the project team was able to complete the cable pulls significantly ahead of schedule. The precise control offered by the winch prevented over-tensioning, leading to zero cable damage throughout the entire installation, a critical success factor that avoided extensive rework and cost overruns. Another compelling case study is in the telecommunications sector, where a regional ISP was rolling out fiber-to-the-home (FTTH) networks in suburban areas. This involved pulling thousands of kilometers of delicate fiber optic cables through existing duct systems and residential conduits. The company opted for lightweight, high-strength fiberglass Fish Tapes and modular cable pulling rollers specifically designed for fiber optic applications. The non-conductive properties of the fiberglass Fish Tapes ensured safety, while the smooth-gliding cable pulling rollers protected the fragile fiber from abrasion and micro-bending losses. This strategic choice of cable pulling tools allowed for rapid deployment, reducing installation time per household by 30% compared to traditional methods, enabling the ISP to quickly expand its service footprint and capture market share. In the renewable energy sector, a large-scale offshore wind farm project faced the daunting task of installing inter-array cables connecting wind turbines to the offshore substation. Due to the immense weight and length of these subsea cables, specialized heavy duty cable rollers and powerful hydraulic cable pulling winch systems were custom-designed for marine environments. These tools were deployed from purpose-built vessels, providing the necessary pulling force and guidance to lay the heavy cables accurately on the seabed, navigating complex underwater topography. The robust construction and corrosion-resistant features of the cable pulling tools ensured reliable operation in the harsh saline environment, proving instrumental in maintaining the project's tight schedule and safeguarding the integrity of the crucial offshore infrastructure. These examples underscore that investment in high-quality, appropriately selected cable pulling tools translates directly into tangible benefits: reduced installation risks, improved operational efficiency, significant cost savings by preventing cable damage and rework, and ultimately, the successful and timely completion of critical infrastructure projects.

Image 6: Highly efficient cable pulling rollers streamlining complex cable installations.

Ensuring Reliability: Quality Assurance and Compliance Standards

For B2B stakeholders, the reliability and safety of cable pulling tools are non-negotiable, directly correlating with operational integrity and project profitability. This inherent trust is built upon rigorous quality assurance processes and strict adherence to international compliance standards throughout the design, manufacturing, and testing phases. Manufacturers committed to excellence will operate under internationally recognized quality management systems, such as ISO 9001:2015, which ensures a systematic approach to quality control from raw material sourcing to final product inspection. This includes meticulous tracking of material batches, precise calibration of manufacturing machinery, and detailed documentation of every production step. Specific performance and safety standards, such as those issued by the American National Standards Institute (ANSI) for lifting and pulling equipment, or European CE marking requirements for machinery, are critical benchmarks. For example, a cable pulling winch should comply with EN 14492-1 (Cranes - Power driven winches and hoists - Part 1: Power driven winches) for safety in operation, while the design and materials of cable tray rollers and heavy duty cable rollers might follow standards related to their load-bearing capacity and material specifications. Beyond formal certifications, comprehensive internal testing protocols are essential. This includes destructive and non-destructive testing (NDT) of materials and components, such as ultrasonic testing for welds and cast parts, magnetic particle inspection for surface cracks, and tensile strength tests on critical load-bearing elements. Every finished cable pulling tool undergoes functional testing, where its maximum pulling capacity, speed consistency, safety shut-off mechanisms, and overall operational integrity are verified under simulated real-world conditions. For instance, a cable pulling winch might be subjected to overload tests at 125% of its rated capacity, or a batch of cable pulling rollers might be tested for their friction coefficient and wear resistance over thousands of cycles. Traceability of components and comprehensive product documentation, including user manuals, maintenance guides, and safety warnings, further enhance product reliability and user confidence. Companies like Bilopowtel emphasize their commitment to quality by subjecting their products to stringent internal tests and adhering to relevant international standards, providing test certificates and compliance reports upon request. This dedication ensures that every piece of equipment, from a simple Fish Tape to a complex cable pulling winch, delivers consistent, safe, and dependable performance, safeguarding the significant investments made in cabling infrastructure and protecting the personnel involved in its deployment. A strong emphasis on adherence to these standards is not merely about compliance; it is about building a foundation of trust and ensuring that the tools perform flawlessly when and where it matters most, contributing to the overall success and safety of global infrastructure projects.

Trust and Support: FAQs, Warranty, and Customer Service Excellence

Establishing strong relationships built on trust is paramount in the B2B sector, particularly for specialized equipment like cable pulling tools where long-term performance and reliable support are critical. Manufacturers demonstrate trustworthiness not only through product quality but also through transparent policies on delivery, comprehensive warranties, and proactive customer support. A robust Frequently Asked Questions (FAQ) section, for example, is an initial touchpoint where common inquiries regarding product selection, usage, maintenance, and troubleshooting for cable pulling winch systems, Fish Tapes, or cable tray rollers can be addressed proactively. This empowers clients with immediate answers, streamlining the pre-sales and post-sales processes. Typical FAQs might cover topics such as: "What is the recommended pulling lubricant for different cable types?" "How do I calculate the maximum pulling tension for my cable?" "What maintenance is required for a heavy duty cable roller?" or "Are spare parts readily available for my cable pulling tools?" Beyond informational resources, clarity on delivery cycles and logistics is vital for project planning. Reputable manufacturers provide clear estimates for lead times, detailed shipping information, and potentially global logistics support, ensuring that cable pulling tools arrive on site when needed, minimizing project delays. For instance, a delivery cycle for standard items might be 2-4 weeks, while custom solutions could require 8-12 weeks, with expedited options available. Crucially, a comprehensive warranty program underpins a manufacturer's confidence in its products. A typical warranty for professional cable pulling tools might range from 1 to 3 years, covering manufacturing defects and material failures under normal operating conditions. This commitment protects the client's investment and provides peace of mind. Furthermore, exceptional customer support encompasses technical assistance, readily available spare parts, and responsive repair services. This includes dedicated technical support hotlines or online portals, field service technicians for complex issues, and easy access to genuine replacement parts for all categories of cable pulling tools, from roller bearings to winch motor components. Bilopowtel exemplifies this commitment by offering comprehensive support, ensuring customers can maximize the lifespan and performance of their equipment. The availability of training programs for client personnel on the safe and efficient operation of cable pulling tools further reinforces a manufacturer's dedication to customer success and safety. Ultimately, this holistic approach to customer service, from initial inquiry to long-term support, builds a foundation of reliability and partnership, crucial for sustained collaboration in demanding industrial environments where downtime is costly and efficiency is key.

Conclusion: The Future of Cable Installation and Infrastructure Development

The indispensable role of advanced cable pulling tools in modern infrastructure development cannot be overstated. As global demand for reliable and high-capacity electrical grids, high-speed communication networks, and advanced industrial automation continues to surge, the efficiency, safety, and precision of cable installation processes become increasingly critical. From robust cable pulling winch systems capable of handling multi-ton loads to meticulously engineered cable tray rollers and heavy duty cable rollers that minimize friction and protect valuable cables, these tools are at the forefront of enabling complex, large-scale projects. The ongoing evolution in manufacturing processes, integrating advanced materials like high-strength alloys and specialized polymers, alongside precision techniques such as CNC machining and comprehensive quality control, ensures that these tools deliver unparalleled performance and longevity, even in the most challenging environments. Furthermore, the integration of smart technologies, including real-time tension monitoring, data logging, and IoT connectivity, is transforming cable installation from a labor-intensive task into a highly optimized, data-driven operation. These innovations not only enhance operational safety and reduce the risk of costly cable damage but also contribute significantly to reducing project timelines and overall energy consumption. The strategic selection of a manufacturing partner, one that demonstrates not only technological prowess but also a strong commitment to quality assurance, customized solutions, and exceptional post-sales support, is vital for B2B decision-makers. As we look to the future, the trends indicate a continued push towards even greater automation, enhanced portability for remote and difficult-to-access sites, and further integration of artificial intelligence for predictive maintenance and optimized pulling operations. The development of greener, more sustainable cable pulling tools that consume less energy and are manufactured with environmentally responsible materials will also be a key focus. Ultimately, by investing in the latest generation of cable pulling tools, industries can ensure the resilience, efficiency, and future-readiness of their critical infrastructure, paving the way for sustainable growth and technological advancement in a connected world.

References and Further Reading

- Grand View Research. (2023). Cable Accessories Market Size, Share & Trends Analysis Report.

- International Organization for Standardization (ISO). (n.d.). ISO 9001 Quality Management.

- Occupational Safety and Health Administration (OSHA). (n.d.). 29 CFR 1926.955 - Overhead Lines. (Relevant safety guidelines for electrical work)

- European Committee for Standardization (CEN). (n.d.). EN 14492-1: Cranes - Power driven winches and hoists - Part 1: Power driven winches. (Standard for winch safety)

- IEEE Xplore Digital Library. (For technical papers on cable installation techniques and tools, membership required for full access to certain papers).

- International Conference on Insulated Power Cables (Jicable). (Provides access to technical papers on cable technologies and installation, specific paper access varies).

The Strategic Imperative of Advanced Cable Pulling Tools in Modern Infrastructure Development

In the intricate and ever-expanding realm of global infrastructure, the efficient and secure deployment of extensive cable networks stands as a cornerstone for progress, underpinning critical sectors from energy transmission and telecommunications to industrial automation and smart city initiatives. The sheer scale and complexity of these projects necessitate highly specialized equipment, particularly high-performance cable pulling tools. These indispensable devices are meticulously engineered to overcome the formidable challenges of long distances, intricate conduit pathways, and the immense weight and rigidity of modern cabling, ensuring flawless installation while rigorously safeguarding both personnel and the valuable cable infrastructure itself. The global market for these specialized cable pulling tools is experiencing an unprecedented surge, primarily fueled by monumental investments in next-generation smart grids, expansive 5G network deployments, ambitious renewable energy projects across continents, and widespread urban revitalization efforts. Industry analysts, such as Grand View Research, underscore this escalating demand, projecting that the global cable accessory market, which comprehensively includes these vital cable pulling tools, was valued at an impressive USD 52.8 billion in 2022 and is poised for substantial expansion at a compound annual growth rate (CAGR) of 6.2% from 2023 to 2030. This robust growth trajectory highlights the increasing recognition among B2B stakeholders of the critical need for reliable, precise, and highly efficient cable installation solutions. Emerging industry trends strongly indicate a transformative shift towards greater automation in cable pulling tools, the integration of advanced safety protocols to mitigate operational risks, and the development of tools specifically designed to handle increasingly larger and heavier cables, often constructed from specialized, high-performance materials that demand exceptional care during handling. Furthermore, the pervasive focus on sustainability and energy efficiency within the construction and infrastructure sectors is profoundly influencing the design philosophies and material selections for modern cable pulling tools, compelling manufacturers to innovate with lightweight yet exceptionally robust composites and sophisticated power systems that inherently reduce operational energy consumption. The inherent complexities of cable installation, encompassing critical aspects such as precise friction management within conduits, the imperative to prevent any form of cable damage (e.g., kinking, stretching, or insulation abrasion), ensuring the absolute safety of skilled workers operating in challenging environments like confined spaces or at significant heights, and maintaining optimal installation speed to meet stringent project deadlines, collectively underscore the absolute necessity for cable pulling tools that offer unparalleled mechanical strength, superior ergonomic design, and intuitive, intelligent control systems. This comprehensive article aims to provide B2B decision-makers with profound insights into the technical intricacies, diverse application scenarios, manufacturing excellence, and profound strategic advantages offered by advanced cable pulling tools, empowering them to optimize their large-scale infrastructure projects and secure a distinct competitive advantage in an intensely demanding global market.

Deep Dive into Cable Pulling Tools: Technology, Principles, and Manufacturing Excellence

The comprehensive category of "cable pulling tools" encompasses an array of sophisticated equipment, each meticulously engineered for specific stages and nuanced challenges inherent in complex cable installation projects. Fundamentally, the overarching objective is to precisely guide and pull cables through diverse pathways, including conduits, open trenches, overhead supports, and intricate cable trays, all while minimizing frictional resistance and maintaining maximum operational control. Central to this suite of essential cable pulling tools are powerful devices like the Cable Puller, often referred to as a power puller or a cable pulling winch, which represents the pinnacle of mechanized assistance in cable installation. This electromechanical or hydraulic marvel is designed to generate substantial pulling forces, typically ranging from several hundreds of pounds to multiple tons, rendering it absolutely indispensable for the installation of exceptionally heavy or extraordinarily long runs of high-voltage power cables, fiber optic bundles, or large communication trunk lines. A typical cable pulling winch comprises a robust motor, a meticulously engineered pulling drum or capstan (a rotating spindle or cylinder), and an advanced control system, which collectively allow operators to precisely manage the pulling speed and maintain consistent tension, thereby preventing any deleterious over-stressing or damage to the cable. The pulling force generated by the cable pulling winch is efficiently transmitted to the cable via a high-strength pulling rope or tape, which is often crafted from advanced synthetic fibers such as Dyneema, renowned for its exceptional strength-to-weight ratio, or durable steel wire, securely attached to a purpose-designed pulling grip at the cable end. In stark contrast, a Fish Tape, though also a critical component among cable pulling tools, serves as a more manual yet equally vital, flexible instrument, typically manufactured from spring steel, high-grade fiberglass, or innovative composite materials. It is predominantly utilized for guiding smaller wires or pilot lines through confined spaces such as narrow conduits, internal wall cavities, or overhead ceiling plenums. The defining characteristics of a Fish Tape are its remarkable flexibility, allowing it to navigate complex bends, combined with sufficient rigidity to effectively push through minor obstructions, making it an ideal choice for residential, light commercial, and less demanding industrial applications where a powerful cable pulling winch would be overkill. Cable tray rollers, also universally known as cable rollers or cable guides, constitute another indispensable category of accessories within the broad spectrum of cable pulling tools. These crucial devices are strategically employed to provide robust support and precise guidance for cables as they are pulled over various obstacles, around sharp bends, or along the ground during the installation process, leading to a significant reduction in frictional forces and effectively preventing abrasion or damage to the cable jacket. These specialized rollers are typically fabricated from exceedingly robust materials such as high-grade aluminum, heavy-duty steel, or high-density polymers, guaranteeing exceptional durability and ensuring ultra-smooth, low-friction operation even under the most demanding loads. For exceptionally large and heavy power cables frequently encountered in critical utility, industrial, and large-scale infrastructure projects, heavy duty cable rollers are specifically engineered. These are distinguished by their reinforced structural frames, larger diameter wheels that facilitate easier movement, and significantly enhanced load-bearing capacities, ensuring they can withstand immense stress without compromising performance. Collectively, the judicious and symbiotic utilization of these diverse cable pulling tools—ranging from the raw power of a cable pulling winch to the precise guidance of cable pulling rollers—ensures an impeccably streamlined, unequivocally safe, and supremely efficient cable installation process, thereby substantially mitigating potential damage to valuable cabling infrastructure and optimizing critical project timelines and budgets.

Image 1: Illustrative application of cable pulling tools in a demanding industrial environment, demonstrating precision and control.

The Advanced Manufacturing Process: Ensuring Uncompromised Precision and Enduring Durability

The manufacturing of high-quality cable pulling tools is a highly sophisticated and multi-stage process, demanding not only exceptional precision engineering but also the judicious selection of exceptionally robust materials and the implementation of uncompromisingly stringent quality control protocols. This rigorous approach is fundamental to ensuring that each final product can reliably endure the exceptionally demanding operational conditions frequently encountered in critical infrastructure projects across diverse industries. The process invariably commences with the scrupulous selection of premium raw materials. For structural components that bear significant loads, such as the frames of cable pulling winch systems or the core elements of heavy duty cable rollers, high-strength alloy steels are often chosen for their superior tensile strength and fatigue resistance. For components where a combination of strength and reduced weight is paramount, such as frames for more portable cable pulling tools, aerospace-grade aluminum alloys are frequently employed. Specialized polymers, like high-density polyurethane (HDPU) or ultra-high molecular weight polyethylene (UHMW-PE), are selected for rollers and protective coatings due to their exceptional wear resistance, low friction properties, and non-marring characteristics, which are vital for protecting the delicate cable jacket during pulls. For critical load-bearing parts, such as the shafts, gears, and capstans within a cable pulling winch, advanced metallurgical processes including precision forging and intricate casting are utilized to create blanks with an optimized internal grain structure. This process significantly enhances their mechanical properties, including ultimate tensile strength, yield strength, and resistance to cyclic fatigue, ensuring operational reliability over extended periods. These meticulously formed blanks then undergo advanced CNC (Computer Numerical Control) machining. This automated process allows for exceptionally precise shaping, intricate drilling, and flawless finishing, guaranteeing exact dimensional tolerances and remarkably smooth surface finishes. Such precision is absolutely critical for the optimal performance of mechanical components and for maximizing their operational lifespan, particularly for moving parts within cable pulling tools where wear resistance is key. For components like cable tray rollers and cable pulling rollers, the manufacturing emphasis extends beyond sheer material strength to encompass the critical aspects of surface finish and bearing quality. Roller wheels themselves are often precision-machined from hardened steel or molded from high-density polyurethane (HDPU), which offers an unparalleled combination of wear resistance, extremely low friction, and non-marring properties, effectively protecting the valuable cable jacket from any surface damage during movement. The integrated bearings within these cable pulling rollers are typically sealed, precision-machined units, explicitly rated for the heavy loads and high duty cycles characteristic of cable pulling operations, often incorporating self-lubricating features to significantly reduce the need for external maintenance and extend service intervals. Beyond the primary shaping processes, vital secondary treatments are applied. Heat treatment processes, such as induction hardening, carburizing, or tempering, are meticulously applied to critical components to further enhance their surface hardness, overall toughness, and wear resistance, particularly crucial for gear teeth and bearing surfaces that experience high contact stresses. Subsequently, advanced surface treatments, including robust powder coating, hot-dip galvanization, or sophisticated anodization, are applied. These treatments provide superior corrosion resistance, an absolutely critical feature for cable pulling tools that are routinely exposed to harsh outdoor environments, high humidity, or various corrosive industrial chemicals. This protective layer not only ensures the tool's aesthetic integrity but, more importantly, drastically extends its operational lifespan, contributing to a lower total cost of ownership. Throughout the entirety of this sophisticated manufacturing pipeline, uncompromisingly rigorous testing protocols are systematically implemented. This includes comprehensive material composition analysis using advanced spectrometry, precise dimensional verification with high-accuracy CMM (Coordinate Measuring Machine) systems, advanced non-destructive testing (NDT) techniques such as ultrasonic inspection or magnetic particle inspection to detect any internal flaws, and dynamic load testing specifically designed to simulate and verify performance under extreme, real-world operational stresses. Adherence to globally recognized international standards, such as ISO 9001 for robust quality management systems, ANSI (American National Standards Institute) standards for performance and safety, and specific European CE marking requirements for machinery, unequivocally ensures that each cable pulling tool meets or surpasses the highest global benchmarks for reliability, safety, and operational excellence. The typical design life of meticulously maintained professional cable pulling tools, when manufactured to these exacting standards, impressively ranges from 10 to 20 years, contingent upon the intensity of usage and the diligence of preventative maintenance schedules. These stringent manufacturing standards make such cable pulling tools absolutely indispensable in industries where high reliability and unwavering safety are paramount. In the petrochemical sector, for instance, these tools are essential for the safe and precise laying of power and control cables in hazardous, potentially explosive areas, where their inherent anti-corrosion features are of critical importance. In the metallurgy industry, robust cable pulling rollers and powerful cable pulling winch systems are vital for handling the exceptionally heavy-duty cables that power furnaces and rolling mills, where minimizing friction is key to preventing damage and ensuring smooth operations. Similarly, in the water supply and drainage sector, these cable pulling tools are fundamental for installing critical power lines for pumping stations and treatment facilities, where their energy-efficient design helps to minimize operational costs. This unwavering focus on unparalleled durability, extreme precision, and application-specific material selection ensures that these cable pulling tools not only perform with exceptional effectiveness but also contribute significantly to long-term operational savings, drastically enhanced safety, and overall project success across an incredibly diverse spectrum of demanding industrial applications.

Image 2: A powerful cable pulling winch meticulously designed for exceptionally heavy-duty applications, showcasing advanced engineering.

Critical Technical Parameters and Performance Metrics of Advanced Cable Pulling Tools

The performance and operational efficacy of cutting-edge cable pulling tools are precisely quantified and defined by a comprehensive array of critical technical parameters that directly and profoundly influence their efficiency, inherent safety, and ultimate suitability for an extensive range of demanding applications. A thorough understanding of these intricate specifications is absolutely essential for B2B professionals, enabling them to confidently select the most optimal equipment for their complex infrastructure projects. For a powerful cable pulling winch or any other powered cable puller, the primary and most paramount parameter is its maximum pulling capacity. This crucial metric is typically measured in kiloNewtons (kN) or pounds (lbs), and it quantifies the absolute maximum force the device can exert on the cable. Typical capacities for these robust cable pulling tools range from a few kN (e.g., 10 kN or approximately 2,200 lbs) for lighter and more agile tasks, up to and exceeding 100 kN (or approximately 22,000 lbs) for the heaviest and longest runs of power cables, such as those used in major utility transmission lines. Another critically important metric is the pulling speed, which is often highly adjustable to accommodate varying site conditions and cable types. This is measured in meters per minute (m/min) or feet per minute (ft/min), and it directly dictates the pace of installation, thereby significantly influencing overall project timelines and efficiency. For instance, a cable pulling winch offering a wide variable speed control range, perhaps from a slow and precise 0.5 m/min for delicate maneuvers to a rapid 15 m/min for open-trench pulls, provides unparalleled versatility and allows for the precise handling of diverse cable types and navigating complex conduit conditions. The type and power output of the motor (e.g., a 2.2 kW electric motor or a 9 HP hydraulic system) also fundamentally define the tool's operational capabilities, its power requirements, and its suitability for continuous duty. For Fish Tapes, essential members of the cable pulling tools family, key specifications include their overall length (commonly available in 30m, 60m, or 100ft, 200ft increments), their precise diameter (e.g., 4mm, 6mm), and their core material composition (fiberglass, spring steel, or advanced composite materials), which collectively dictate their flexibility, necessary rigidity for pushing, and inherent resistance to kinking and permanent deformation. For cable tray rollers and heavy duty cable rollers, vital parameters include their individual load-bearing capacity per roller unit (e.g., ranging from 500 kg for standard applications to over 2000 kg for exceptionally heavy cables), the specific material of the roller wheel itself (e.g., durable aluminum, robust steel, or high-performance HDPU), the wheel's diameter, and the precise type of bearing system employed (e.g., sealed precision ball bearings for minimal friction, or robust plain bearings for high impact resistance). These attributes collectively determine their crucial friction reduction capabilities, their ability to withstand continuous heavy loads, and their long-term durability. The design configuration of the roller frame—whether a straight-line roller, a specialized corner roller, or an articulated roller designed for duct entry—also profoundly impacts its functional performance. Corner rollers, for example, typically feature multiple, precisely angled wheels to guide cables with exceptional smoothness through sharp turns, thereby significantly reducing harmful side wall pressure on the cable jacket. The coefficient of friction, though often an indirect performance indicator not explicitly specified, is a paramount factor for all cable pulling tools that interact with the cable surface; a lower coefficient translates directly into less pulling force required from the cable pulling winch, which in turn results in reduced cable stress, minimized insulation degradation, and lower operational energy consumption. Many cutting-edge cable pulling tools now integrate advanced features such as sophisticated electronic tension monitoring systems, which provide real-time, precise feedback on the instantaneous pulling force being applied. This crucial data allows operators to prevent dangerous over-tensioning, a primary cause of catastrophic cable damage. Furthermore, integrated data logging capabilities are becoming increasingly common, allowing for comprehensive post-installation analysis of pulling parameters, which is invaluable for quality assurance, compliance documentation, and optimizing future operations. Practical operational parameters, such as the tool's portability (its overall weight and physical dimensions) and the ease and speed of its setup, are also highly influential in determining overall operational efficiency, particularly on complex and often constrained job sites. Environmental ingress protection ratings (IP standards for dust and water resistance) are absolutely vital for cable pulling tools destined for use in outdoor or harsh industrial environments, ensuring prolonged reliability. By meticulously considering these detailed technical parameters, B2B procurement teams can perform a highly effective comparative analysis of different models and manufacturers, thereby ensuring that the selected cable pulling tools not only robustly meet current project demands but also deliver exceptional long-term reliability and demonstrably superior cost-effectiveness, safeguarding critical investments in infrastructure.

Image 3: Cable tray rollers strategically positioned to minimize friction and prevent cable damage during complex installation maneuvers.

Comparative Analysis of Key Specifications (Illustrative Data for Diverse Cable Pulling Tools)

Diverse Application Scenarios and Sector-Specific Advantages of Cable Pulling Tools

The indispensable utility and profound versatility of cable pulling tools extend across an incredibly broad spectrum of industrial, commercial, and utility sectors, with each distinct industry presenting its own unique set of engineering challenges that these specialized devices are uniquely designed to comprehensively address and overcome. In the dynamic and rapidly expanding energy sector, particularly within the context of massive renewable energy generation projects such as vast solar farms and towering wind turbine installations, the installation of intricate high-voltage transmission lines demands the formidable power of advanced cable pulling winch systems. These systems must be capable of efficiently handling extraordinary lengths and immense weights of power cables across highly varied and often challenging terrains. In such critical applications, the paramount emphasis is placed on minimizing costly downtime and meticulously preserving the integrity of the cable's insulation throughout the entire installation process, where the precise tension control and impeccably smooth guidance provided by advanced cable pulling rollers are absolutely crucial for success. For large-scale urban infrastructure development initiatives, including complex underground utility installations for burgeoning new residential districts or expansive commercial complexes, heavy duty cable rollers prove to be utterly indispensable. They enable the seamless navigation of massive cables through dense existing networks of conduits and around tight, unforgiving bends, thereby preventing any form of damage to both the valuable cables themselves and the surrounding subterranean structures. In the fiercely competitive telecommunications industry, specifically with the accelerated global rollout of fifth-generation (5G) networks and expansive fiber optic broadband infrastructure, the rapid and delicate deployment of sensitive fiber optic cables necessitates specialized cable pulling tools. This includes lightweight yet robust Fish Tapes crafted from advanced composite materials for precise, long-distance pulls through congested conduits, complemented by lightweight, low-friction cable tray rollers for the efficient and safe routing of cables within sophisticated data centers and critical communication hubs. The omnipresent manufacturing sector, ranging from highly automated automotive production plants to heavy machinery fabrication facilities, continuously expands and upgrades its automated production lines, which inherently necessitates the frequent installation and maintenance of vast and intricate networks of control, data, and power cables. Here, cable pulling tools facilitate remarkably quick and unequivocally safe installations, thereby minimizing costly disruptions to demanding production schedules and maintaining operational continuity. The petrochemical industry, characterized by inherently hazardous explosive atmospheres and intensely corrosive operating environments, relies heavily on specialized cable pulling tools that are explicitly designed with intrinsically safe components and feature advanced corrosion-resistant coatings. This ensures the unwavering integrity of the electrical systems that power critical process controls and essential safety mechanisms in such volatile settings. In monumental large-scale construction projects, whether it involves the erection of towering skyscrapers or the development of sprawling industrial complexes, these cable pulling tools are utterly essential for both vertical and horizontal cable runs. They ensure that electrical, data, and communication cables are installed with exceptional efficiency and uncompromising safety, often under the duress of extremely tight deadlines. The marine and offshore industry represents another challenging domain where exceptionally robust cable pulling tools are deployed for the precise laying of crucial subsea cables for both power transmission and high-speed data transfer. In these environments, characterized by extreme ocean depths and relentlessly harsh saline conditions, the equipment must possess unparalleled durability and unwavering reliability. Even in vital sectors such as municipal water supply and drainage systems, where reliable power cables are absolutely vital for critical pumps and intricate control systems, the capability to rapidly and safely install cables in damp, corrosive, or subterranean environments is paramount. The collective advantages realized across these diverse sectors are substantial and measurable: significantly reduced cable installation times, dramatically enhanced worker safety by minimizing manual handling of heavy and awkward cables, robust protection of exceptionally valuable cable assets from abrasion, excessive tension, or kinking, and ultimately, a substantial reduction in overall project costs. The remarkable adaptability of these cable pulling tools, ranging from small-scale residential wiring applications utilizing nimble Fish Tapes to colossal power line installations demanding multi-ton cable pulling winches and an array of sophisticated cable pulling rollers, unequivocally underscores their universal and critical importance in the relentless pursuit of modern industrial operational excellence.

Image 4: Robust heavy duty cable rollers meticulously deployed to facilitate the seamless installation of large power cables in challenging conditions.

Technological Advantages, Innovations, and Economic Benefits in Cable Management

The relentless pace of innovation in the design and engineering of modern cable pulling tools is consistently yielding profound technological advantages, which directly translate into significantly enhanced operational efficiency, substantial cost reductions, and markedly improved safety standards across virtually all cable installation projects. One of the most prominent and impactful advantages lies in the area of superior friction management. Contemporary cable tray rollers and advanced cable pulling rollers are meticulously engineered with cutting-edge, low-friction materials such as Ultra High Molecular Weight Polyethylene (UHMW-PE) or incorporate precision-machined, self-lubricating bearings. These innovative design elements dramatically reduce the coefficient of friction between the delicate cable surface and the guiding components of the cable pulling tools. This substantial reduction in friction directly results in a significantly lower requirement for pulling force from the cable pulling winch, thereby critically minimizing the mechanical stress exerted on the cable and drastically reducing the risk of costly insulation damage, harmful stretching, or irreversible kinking. The reduced force requirement also directly translates into lower energy consumption for all powered pulling equipment, leading to substantial operational savings over the lifetime of a project and aligning perfectly with burgeoning global initiatives for enhanced energy efficiency and reduced carbon footprint. Furthermore, the seamless integration of sophisticated intelligent control systems, such as precise real-time digital tension readouts and automated shut-off mechanisms, within advanced cable pulling tools, represents a monumental leap forward in preventing dangerous over-tensioning—a leading cause of catastrophic cable failure during installation. These intelligent systems furnish operators with instantaneous, highly accurate feedback, enabling immediate and precise adjustments to the pulling force and speed. This ensures the absolute integrity of the cable throughout the entire pulling operation, a feature that is particularly critical for the installation of exceedingly expensive, high-voltage power cables or fragile fiber optic bundles. Many high-end cable pulling tools now offer comprehensive data logging capabilities, allowing for meticulous post-installation analysis of pulling parameters, which is invaluable for quality assurance, compliance auditing, and continuous process optimization. Another critically important advantage is the enhanced corrosion resistance inherent in many modern cable pulling tools. Tools specifically designed for rigorous outdoor use or for deployment in harsh industrial environments, such as those found in the petrochemical, mining, or marine sectors, frequently feature specialized protective coatings. These may include durable hot-dip galvanization, resilient zinc plating, or advanced multi-layer powder coats, often combined with the strategic use of inherently corrosion-resistant materials such as high-grade stainless steel or marine-grade aluminum components. This robust, multi-faceted protection against rust, oxidation, and chemical degradation significantly extends the operational lifespan of the equipment, substantially reduces the frequency of costly maintenance interventions, and guarantees exceptionally reliable performance even in the most corrosive atmospheres, thereby contributing to a considerably lower total cost of ownership. Beyond these technical advancements, ergonomic design principles and inherent modularity play a vital role in enhancing the utility of these cable pulling tools. Many contemporary designs are engineered for rapid assembly and disassembly, facilitating unparalleled ease of transport between job sites and seamless compatibility with various pulling setups. This modularity optimizes site logistics, drastically reduces manual labor efforts, and accelerates deployment times. The judicious use of lightweight yet exceptionally high-strength materials, such as advanced aerospace-grade aluminum alloys and cutting-edge composites, ensures that essential cable pulling tools like heavy duty cable rollers can effortlessly withstand immense loads without becoming excessively cumbersome. This enhances maneuverability, reduces operator fatigue, and improves overall safety. The cumulative effect of these profound technological advancements across the entire spectrum of cable pulling tools is the realization of a vastly more precise, remarkably efficient, and unequivocally reliable cable installation process that not only meets but often exceeds the stringent demands of modern infrastructure development, while concurrently delivering tangible economic and safety benefits that translate directly into competitive advantage for B2B enterprises.

Strategic Manufacturer Selection and Custom Solutions for Cable Pulling Tools

The judicious selection of the appropriate manufacturer for cable pulling tools represents a profoundly strategic decision for any B2B enterprise engaged in infrastructure projects, directly correlating with the ultimate success of the project, the optimization of operational efficiency, and the maximization of long-term cost-effectiveness. The global market for these specialized tools is populated by numerous manufacturers, each possessing varying strengths in terms of their product range, their commitment to technological innovation, the quality of their customer support, and their unwavering adherence to stringent international standards. When diligently evaluating potential manufacturing partners for your cable pulling tools, a multitude of critical considerations should inform your decision-making process. Foremost among these is the manufacturer's proven track record and established reputation within the industry, which can be effectively gauged by their extensive years of service, the comprehensiveness of their project portfolios, and the volume and quality of positive client testimonials. A manufacturer's demonstrated commitment to continuous research and development (R&D) is a vital indicator, signaling their proactive ability to integrate the latest cutting-edge technologies, such as advanced IoT-enabled tension monitoring systems, sophisticated data analytics for pulling operations, or groundbreaking advancements in material science, directly into their evolving range of cable pulling tools. Certifications play an absolutely pivotal role in unequivocally establishing a manufacturer's credibility and adherence to global best practices; therefore, B2B buyers should actively seek manufacturers who hold universally recognized quality management system certifications like ISO 9001:2015, which rigorously demonstrates their consistent product quality, and explicit adherence to specific regional and international safety standards such as OSHA (Occupational Safety and Health Administration) guidelines or the European CE marking requirements for machinery, guaranteeing compliance with critical regulatory frameworks. Furthermore, the breadth and depth of their available product catalog are exceptionally important – does the manufacturer offer a comprehensive suite of cable pulling winch systems, an expansive variety of cable tray rollers and heavy duty cable rollers, and a diverse selection of specialized Fish Tapes to address every conceivable need? A broad and deep product portfolio indicates a manufacturer's robust capability to effectively address highly diverse project requirements and specific application nuances for all types of cable pulling tools. Beyond the standard off-the-shelf offerings, the manufacturer's inherent capability to provide highly customized solutions stands as a significant and often decisive differentiator. Many large-scale infrastructure projects frequently encounter unique and unforeseen challenges – these might include unusually complex conduit configurations, requirements for exceptionally long pulls across difficult terrains, or the need to install highly specialized cable types with unique handling requirements – challenges that standard, mass-produced cable pulling tools cannot fully or optimally address. In such scenarios, a manufacturer capable of offering bespoke engineering services, ranging from designing custom-sized cable pulling rollers to developing an entirely specialized cable pulling winch with tailored pulling capacities or precise control algorithms, can provide an unparalleled competitive advantage. This often necessitates a close and iterative collaboration between the client's engineering and project management teams and the manufacturer's dedicated R&D and design departments. Such highly specialized customization ensures optimal tool performance for unique, complex applications, effectively preventing costly project delays, mitigating the risk of irreparable cable damage, and significantly enhancing overall operational efficiency. Moreover, thoroughly evaluating a manufacturer's global supply chain resilience and their robust after-sales support network, which includes prompt spare parts availability, readily accessible technical assistance, and comprehensive training programs, is absolutely critical for minimizing costly operational downtime and ensuring the prolonged longevity of your significant capital investment in cable pulling tools. A truly reliable partner will not only offer robust product warranties but also provide responsive and proactive customer service, unequivocally reflecting their profound confidence in their product quality and their unwavering commitment to achieving complete client satisfaction. For instance, Bilopowtel stands out prominently in the industry for its unwavering dedication to high-quality manufacturing processes, its meticulous adherence to stringent international standards, and its strong, client-centric emphasis on providing highly tailored solutions explicitly designed to meet specific industrial needs. This is demonstrably evidenced by their extensive and comprehensive product range and their client-centric approach, ensuring that their cable pulling tools are not merely commodities but rather integral and strategic components that are fundamental to the success of any large-scale infrastructure project.

Image 5: An example of a highly customized cable pulling tool engineered precisely for specific and unique project requirements, showcasing specialized capabilities.

Real-World Application Cases and Compelling Success Stories with Cable Pulling Tools