-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Aug . 15, 2024 18:37 Back to list

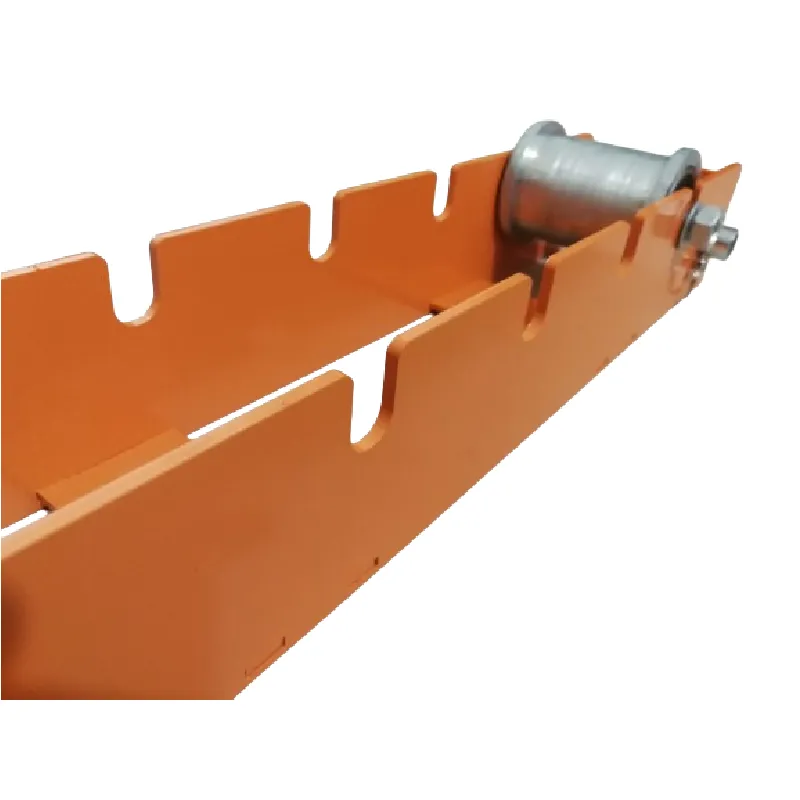

Effective Techniques for Repairing Chain Pulleys and Ensuring Optimal Performance in Machinery

Chain Pulley Repair Ensuring Optimal Performance and Longevity

Chain pulleys are critical components in various mechanical systems, including cranes, hoists, and conveyor belts. They play a vital role in lifting heavy loads and facilitating smooth movement. However, like any mechanical part, chain pulleys are susceptible to wear and tear over time. Proper maintenance and timely repairs are essential to ensure their performance and longevity. This article will guide you through the essential steps for effective chain pulley repair.

Understanding Chain Pulleys

Before delving into repair procedures, it is important to understand the function of chain pulleys. A chain pulley system typically consists of a wheel with a grooved rim that works in conjunction with a chain. As the chain moves over the pulley, it translates into lifting or moving heavy objects. The efficiency of this system largely depends on the condition of the pulley, and neglect can lead to significant operational issues.

Signs That Repair Is Needed

Recognizing the signs that a chain pulley requires repair is crucial in maintaining operational effectiveness. Common indicators include excessive noise during operation, visible wear on the pulley’s surface, uneven chain wear, and reduced lifting capacity. If any of these symptoms are detected, it is advisable to take immediate action to prevent further damage.

Steps for Chain Pulley Repair

1. Safety First Before beginning any repair work, ensure that all safety protocols are followed. Disconnect power to the machinery and use appropriate personal protective equipment (PPE).

2. Inspection Carefully inspect the pulley for signs of damage, such as cracks, deformation, or corrosion. Check the alignment of the pulley with the chain, and ensure that it is securely mounted.

chain pulley repair

3. Cleaning Remove dirt, grease, and debris that may have accumulated on and around the pulley. A clean surface allows for better assessment and prevents contaminants from causing further wear.

4. Check the Chain Examine the chain that works with the pulley. Look for signs of wear, such as elongation or links that are stiff. If the chain is worn, it may need to be replaced.

5. Repairing or Replacing the Pulley If the pulley is damaged but repairable, you can often address minor issues, such as replacing bearings or bushings. However, if the pulley is severely damaged, it is recommended to replace it entirely.

6. Proper Lubrication Once repairs are made, ensure that the pulley is adequately lubricated. This will minimize friction and wear on both the pulley and the chain, enhancing the overall efficiency of the system.

7. Reassembly and Testing After completing the repairs and ensuring everything is in order, reassemble the pulley system and conduct a test run. Monitor the operation closely to ensure that repair work has improved functionality.

Preventive Measures

To avoid the need for frequent repairs, implementing a preventive maintenance plan is crucial. Regular inspections, timely lubrication, and prompt addressing of minor issues can significantly extend the life of your chain pulleys. Training operators on the proper use of equipment can also help reduce wear and tear.

Conclusion

Chain pulley repair is an essential aspect of maintaining efficient mechanical operations. By recognizing the signs of wear, following proper repair procedures, and implementing preventive maintenance, you can ensure that your chain pulley systems operate safely and efficiently for years to come. Investing the time and resources into proper maintenance will not only enhance productivity but also save costs associated with unexpected breakdowns and replacements.

Latest news

Understanding Earth Wiring and Grounding: Essential Components for Electrical Safety

NewsAug.15,2025

The Ultimate Guide to Cable Pulling Tools and Equipment for Efficient Installations

NewsAug.15,2025

Streamline Your Projects with Advanced Cable Pulling Equipment

NewsAug.15,2025

Simplify Cable Installation with Advanced Cable Pulling Tools and Equipment

NewsAug.15,2025

Essential Guide to Link Sticks and Hot Sticks for Electrical Safety and Line Work

NewsAug.15,2025

Efficient Solutions for Cable Installation: Your Guide to Cable Pulling Winches and Equipment

NewsAug.15,2025