-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Aug . 16, 2024 16:11 Back to list

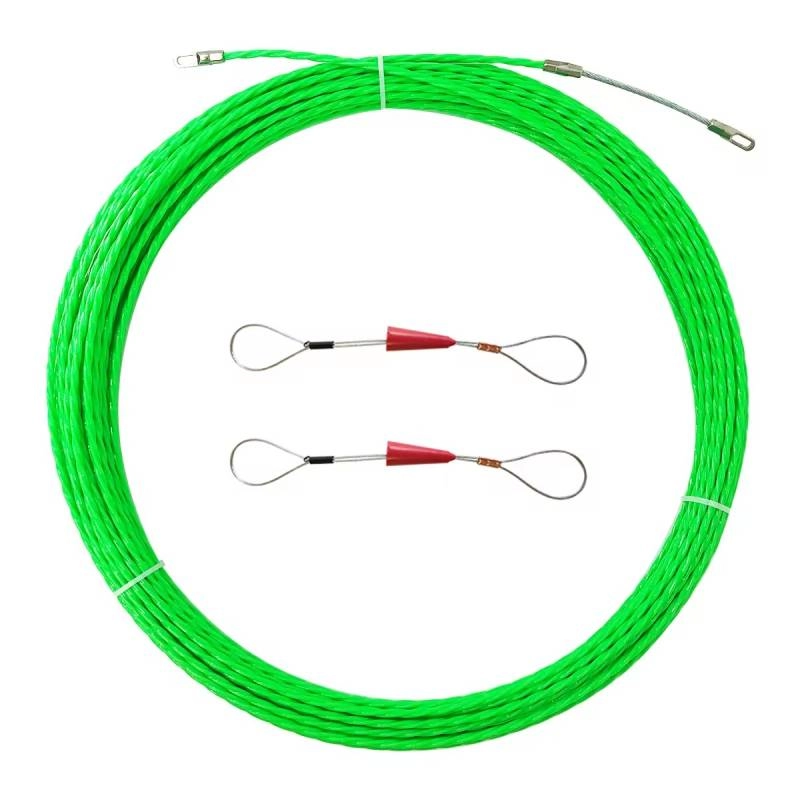

Durable Metal Cable Wrap for Enhanced Protection and Organization of Cables

The Versatility of Metal Cable Wraps A Comprehensive Guide

In today’s fast-paced technological world, the need for organized and efficient cable management solutions has become paramount. Among various methods and materials available for bundling and protecting wires, metal cable wraps have emerged as a popular choice due to their exceptional durability and versatility. This article explores the benefits, applications, and techniques associated with metal cable wraps, providing insights into why they are an indispensable tool for both professionals and hobbyists alike.

What Are Metal Cable Wraps?

Metal cable wraps are flexible, often corrugated tubes made from metal, typically steel or aluminum. They are designed to encase and protect electrical wires and cables from environmental damage, wear and tear, and electromagnetic interference. These wraps come in various sizes and thicknesses, allowing users to choose the appropriate wrap for specific applications.

Benefits of Using Metal Cable Wraps

1. Durability and Strength One of the primary advantages of metal cable wraps is their remarkable durability. Unlike plastic wraps, which can become brittle over time or be prone to tearing, metal cable wraps maintain their integrity under extreme conditions, making them ideal for industrial and outdoor applications.

2. Heat Resistance Metal wraps can withstand high temperatures without degrading, offering a significant advantage in environments where cables may be exposed to heat sources. This quality makes them suitable for use in automotive and aerospace sectors.

3. Shielding and Protection Metal wraps provide excellent shielding against electromagnetic interference (EMI) and radio frequency interference (RFI). This makes them particularly useful in electronic devices where signal quality is critical.

4. Corrosion Resistance Many metal cable wraps come with protective coatings, such as zinc or powder coating, which enhance their resistance to corrosion and environmental damage. This feature extends their lifespan, especially in humid or saline conditions.

5. Aesthetic Appeal In settings where visibility matters, such as in modern design or show-quality installations, metal cable wraps can provide a sleek and professional look. They can be finished in various colors and textures to match the design aesthetic.

Applications of Metal Cable Wraps

The uses of metal cable wraps are diverse and widespread, including

metal cable wrap

- Industrial Equipment In manufacturing, metal cable wraps protect wiring from mechanical stress, chemicals, and extreme temperatures, ensuring the longevity of machinery and electrical components.

- Automotive Industry In vehicles, metal wraps are utilized to encase wiring systems that may be exposed to heat, abrasion, and harsh weather conditions. This enhances safety and minimizes failures.

- Telecommunications For telecommunications infrastructure, where wiring is often laid outdoors, metal wraps protect against animal interference and environmental factors, ensuring reliable performance over time.

- Home Theater Systems Enthusiasts and installers often use metal wraps to manage speaker and power cables, providing a clean, organized appearance while protecting from potential damage.

Techniques for Using Metal Cable Wraps

Using metal cable wraps involves some straightforward techniques

1. Measure and Cut Determine the length of the cable you want to wrap, and cut the metal wrap to the necessary length. Ensure that you have ample coverage to protect connections.

2. Insert Cables Slide the cables into the wrap, ensuring they are properly aligned and not twisted to avoid any tension on the wires.

3. Seal Ends Once the cables are secured within the wrap, seal the ends to prevent any ingress of dirt or moisture. This can be done using end caps or clamps specifically designed for metal wraps.

4. Secure Installation If necessary, use mounting clips to secure the cable wraps in place, particularly in vertical installations where gravity may otherwise cause them to sag.

In conclusion, metal cable wraps are an essential solution for anyone looking to protect and organize their cables effectively. Their durability, heat resistance, and ability to shield against interference make them indispensable in a wide array of applications, from industrial settings to home entertainment systems. By choosing the right metal cable wrap and employing proper installation techniques, users can ensure the safety and longevity of their wire management systems.

Latest news

Understanding Earth Wiring and Grounding: Essential Components for Electrical Safety

NewsAug.15,2025

The Ultimate Guide to Cable Pulling Tools and Equipment for Efficient Installations

NewsAug.15,2025

Streamline Your Projects with Advanced Cable Pulling Equipment

NewsAug.15,2025

Simplify Cable Installation with Advanced Cable Pulling Tools and Equipment

NewsAug.15,2025

Essential Guide to Link Sticks and Hot Sticks for Electrical Safety and Line Work

NewsAug.15,2025

Efficient Solutions for Cable Installation: Your Guide to Cable Pulling Winches and Equipment

NewsAug.15,2025