-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Dec . 18, 2024 05:00 Back to list

driving ground rods in rocky soil

Driving Ground Rods in Rocky Soil Techniques and Considerations

Grounding systems are a critical component of electrical installations, ensuring safety by providing a pathway for fault currents to dissipate into the earth. While driving ground rods is generally a straightforward task in many soils, rocky terrain presents unique challenges that require specific techniques and considerations. This article will explore the process of driving ground rods in rocky soil, the tools needed, and the best practices to ensure effective grounding.

Importance of Grounding

Before delving into the intricacies of installation in rocky soil, it’s essential to understand why grounding is necessary. Grounding protects equipment and sensitive electronic devices from voltage spikes, prevents electrical shocks, and creates a reference point for the electrical system. Proper grounding is particularly crucial in environments where lightning strikes are a concern or in areas with unstable power sources.

Choosing the Right Ground Rod

When working in rocky soil, selecting the appropriate type and length of ground rod is essential. The most common materials for ground rods are copper and galvanized steel. Copper rods are more resistant to corrosion but can be more expensive than their steel counterparts. The length of the rod should also be considered; a common length is 8 feet, but longer rods may be necessary in rocky soil to reach more conductive layers. In some cases, multiple rods may need to be installed in a grounding grid to lower resistance.

Tools Required

Having the right tools is key when installing ground rods in challenging soil conditions

1. Hammer Drill A heavy-duty hammer drill is essential for breaking through solid rock. It provides the necessary force to penetrate rocky or compacted soil.

2. Ground Rod Driver This tool is specifically designed to drive ground rods into the earth. It can be used manually or attached to a hammer drill to augment its impact.

3. Auger In extremely rocky conditions, a soil auger may be used to create a pilot hole for the ground rod, making it easier to drive into the ground.

driving ground rods in rocky soil

4. Level and Measuring Tape Ensuring that the rod is vertical and positioned correctly is crucial for effective grounding.

5. Protective Gear Always wear safety glasses and gloves when using power tools to protect against debris and injury.

Techniques for Driving Ground Rods in Rocky Soil

1. Site Assessment Before starting, perform a thorough assessment of the site to identify any obstacles or particularly hard rock areas. This knowledge will help in planning the installation strategy.

2. Pilot Hole Creation In very rocky areas, it can be advantageous to use an auger to create a pilot hole. This reduces the amount of force needed to drive the rod and minimizes the risk of damaging it.

3. Use of a Hammer Drill Once a pilot hole is established, a hammer drill can be employed to drive the ground rod more effectively. The combined rotational and percussive action of the hammer drill helps penetrate through hard soil and rock.

4. Gradual Insertion Drive the ground rod slowly and gradually, applying consistent pressure. If there is significant resistance, it may be necessary to stop and evaluate the situation, perhaps switching to an auger or using a different rod location.

5. Testing Resistance After installing the ground rod, it is crucial to test its resistance to ground using an ohmmeter. The resistance should typically be below 25 ohms for effective grounding. If the resistance is too high, additional rods may need to be installed, or alternative grounding methods explored.

Conclusion

Driving ground rods in rocky soil is undoubtedly more challenging than in softer ground. However, with the right tools, techniques, and careful planning, it is possible to achieve an effective grounding system. Proper grounding is not just a regulatory requirement; it is a vital component of any electrical installation that ensures safety and reliability. By understanding the unique challenges posed by rocky soil and employing the correct methods, installers can overcome these obstacles and secure a robust grounding system.

Latest news

What Are Construction Tools and How Are They Used?

NewsJul.11,2025

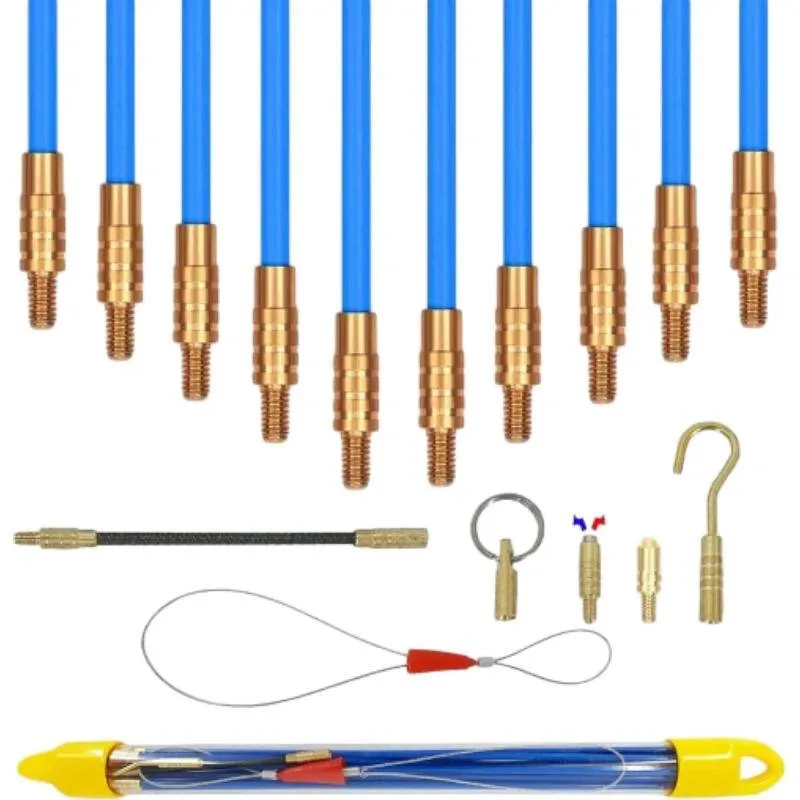

Professional-Grade Duct Rodding Tools for Superior Cable Installation

NewsJul.11,2025

Enhancing Safety and Efficiency with Modern Hot Stick Solutions

NewsJul.11,2025

Empowering Cable Installation with Advanced Rodder Solutions

NewsJul.11,2025

Elevate Your Cable Installation Projects with Cable Pulling Tools

NewsJul.11,2025

Efficient Cable Handling Solutions: Cable Rollers for Sale

NewsJul.11,2025