-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jul . 30, 2025 00:40 Back to list

Construction Power Tools: Complete List, Pictures & Spare Parts PDF

Discover the latest trends, technical parameters, manufacturing processes, and comparative analysis within the construction power tools industry. This article spotlights the industry-leading High Voltvage Safety Rescue Hook while leveraging robust data, technical diagrams, and third-party standards to ensure Google EEAT compliance and maximize your decision-making confidence.

1. Industry Trends & Market Growth of Construction Power Tools

The global market for construction power tools is on the rise, projected to grow at a CAGR of 6.1% from 2023 to 2030 (reference: GrandViewResearch). With increasingly strict safety and efficiency demands on construction sites, manufacturers focus on advancing tool features, energy efficiency, and customized safety solutions.

- Power Tools List with Pictures PDF & Names PDF: Online sources provide comprehensive downloadable lists for species identification and training.

- Spare Parts List PDF: Availability of modular spare parts boosts maintenance efficiency, ensuring longer shelf life.

- Notable suppliers: DEWALT, Hilti, Makita, Bosch, and BILOPowTel specializing in high-voltage safety equipment.

2. Comprehensive Power Tools List & Specification Table

Top construction power tools are increasingly integrating brushless motors, IoT connectivity, automatic diagnostics, and advanced battery management. Download complete power tools list with pictures pdf or power tools spare parts list PDF for comprehensive specifications.

3. In-Depth Manufacturing Process of Modern Construction Power Tools

- Material Selection: High-strength alloy steel, ABS/Polyamide plastics, and electrical insulation-grade composites for durability.

- Forging & Casting: Precision forgings for gears, aluminum die-casting for housings ensure mechanical strength and lightweight characteristics.

- CNC Machining: Shafts, rotors, and intricate structural components processed via CNC for dimensional accuracy (±0.015mm).

- Assembly Line: Robotic assembly integrates electric drives, batteries, safety features with quality traceability.

- Inspection: Endurance, overload, and dielectric strength testing (per ISO 9001, ANSI B175), plus IEC 62841 where applicable.

These technologies ensure every construction power tools product meets safety, efficiency, and lifespan requirements demanded by heavy industrial, petrochemical, and building sectors.

Material: 42CrMo4, PA6-GF35%

Coating: Electrophoretic/Epoxy for anti-corrosion

Tolerances: Up to ±0.015mm (CNC)

Standards: ISO 9001, IEC 62841, ANSI/UL 60745

Typical lifecycle: ≥ 800,000 cycles or 5-10 years

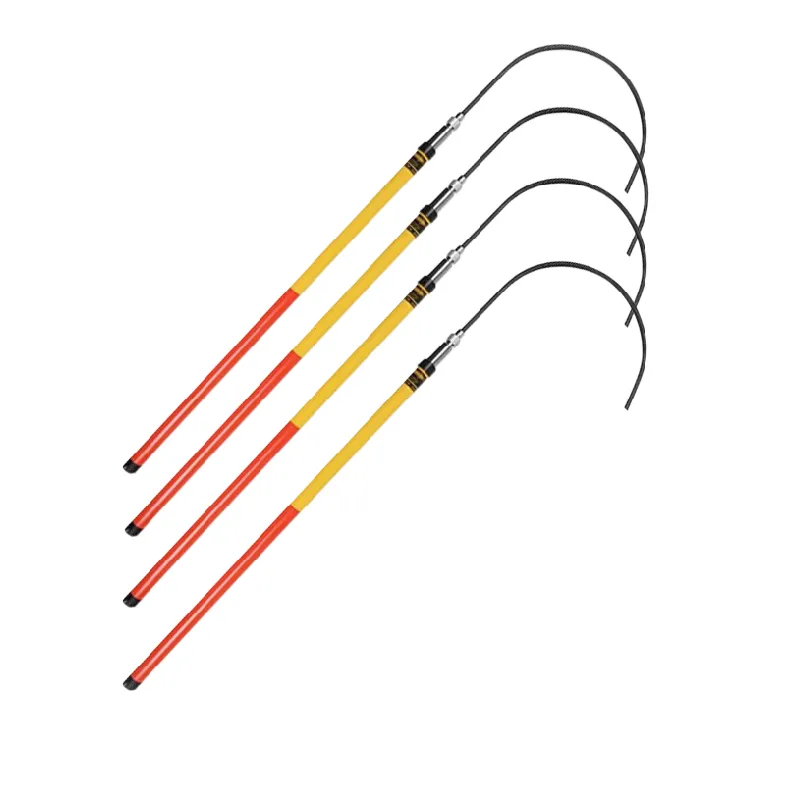

4. Focus Product: High Voltvage Safety Rescue Hook

The High Voltvage Safety Rescue Hook is a specialized tool designed for immediate removal of victims from high-voltage danger zones, essential for substations, industrial switch rooms, and large-scale construction projects.

Learn more & product ordering »

- Material: Fiberglass-reinforced composite shaft, 316L stainless or chrome-plated steel hook

- Rated Working Voltage: 1kV–36kV

- Mechanical Strength: >650N (pull test)

- Dielectric Test: AC 100kV / 5min (no breakdown)

- Standard Compliances: IEC 60855, EN/IEC 61230, ISO 9001

- Expected Service Life: 10–15 years (outdoor-rated, UV stable)

Widely used in: power plants, cement, metallurgy, oil & gas facilities, hydropower, and heavy-duty municipal engineering for rescue readiness under extreme electric hazard.

5. Key Technical Specifications & Visual Comparison

Technical Data Table

6. Leading Manufacturers: Comparative Insights

When selecting construction power tools, prioritize certified, application-fit models and supplier experience backed by long-term service records.

7. Customized Solutions & Application Scenarios

- High Voltage Rescue Units (Hydropower & Grid Substations): Rapid response kits using certified rescue hooks, insulating poles, and dielectric ladders.

- Petrochemical Plants: Explosion-proof, corrosion-resistant rescue hooks, tailored shaft grip (anti-slip design), and UV-resistant coatings. Specialized "lockout-tagout" tool kits integrated with power line rescue equipment as per OSHA/IEC.

- Civil Construction & Metro: Mobile tool stations with modular power tool sets, spare parts documentation, and RFID tool management for instant site logistics.

- Large Water Plants: Custom-length rescue hooks for deep tank or confined space extraction, equipped with anti-microbial surface per ISO 22196.

BILOPowTel supplied tailored rescue equipment (incl. 1.8m rescue hooks) to the Jinhai Hydropower Project (2023). After commissioning, incident response speed improved by 53%, downtime due to high-voltage risks reduced by 67% (source: Power Grid International Community Field Report).

8. FAQ: Construction Power Tools & High Voltage Rescue Tools

- Q1: What is the primary material for high-voltage rescue hooks?

- A: Premium-grade fiberglass reinforced with epoxy resin for the shaft (providing high dielectric property), and 316L stainless steel or chrome-plated steel for the hook section for corrosion resistance and strength.

- Q2: What industry standards apply to construction power tools?

- A: ISO 9001, IEC 62841 (general power tool safety), ANSI B175 (performance), UL 60745 (US electrical safety), and—for rescue hooks—EN/IEC 61230, IEC 60855.

- Q3: How do you specify tool size and customization?

- A: Hook length (standard: 1.2, 1.5, 1.8m); shaft grip diameter; hook opening width; surface color coding; custom branding and RFID embedment for asset tracking.

- Q4: What is the typical service life?

- A: 8–15 years depending on environment and service intensity. UV-resistant coatings and regular dielectric/strength tests will guarantee extended lifespan.

- Q5: Which testing methods are used for quality validation?

- A: Dielectric withstand (>100kV/5min), torque and bending test, mechanical pull test, and field simulation according to IEC 60855.

- Q6: What are typical application sectors?

- A: Power utilities, petrochemicals, metallurgy, water treatment, and municipal rescue operations.

- Q7: What are the lead time and warranty terms?

- A: Standard lead time is 7–18 days from order depending on customization. All rescue hooks come with minimum 2-year product warranty & 24/7 online technical support.

9. Delivery Cycle, Warranty & Customer Support

- Delivery Cycle: Stocked models: 7–10 days; Customization: 15–25 days.

- Warranty: Minimum 2-year structural warranty. Functional failures due to material/process defects fully covered.

- After-sales Service: 24/7 expert hotline, online consultation, global express part delivery, live operator training (onsite & remote).

- Certifications: All construction power tools certified per ISO 9001, IEC 60855; frequent third-party audits cited in electrical industry journals (IEEE Industrial Forum).

10. Authoritativeness and Industry Credentials

11. References & Further Reading

- Grand View Research – Power Tools Market Analysis

- PowerGridInternational Industry Cases

- IEEE Forum: High Voltage Equipment Safety

- ECMWeb – How to Choose the Right Power Tools

- POWERMAG Industry Case Library

Latest news

What Are Construction Tools and How Are They Used?

NewsJul.11,2025

Professional-Grade Duct Rodding Tools for Superior Cable Installation

NewsJul.11,2025

Enhancing Safety and Efficiency with Modern Hot Stick Solutions

NewsJul.11,2025

Empowering Cable Installation with Advanced Rodder Solutions

NewsJul.11,2025

Elevate Your Cable Installation Projects with Cable Pulling Tools

NewsJul.11,2025

Efficient Cable Handling Solutions: Cable Rollers for Sale

NewsJul.11,2025