-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

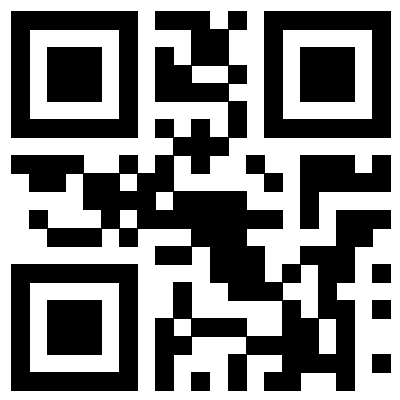

TEL:

0086-311-88862036

Jan . 24, 2025 00:45 Back to list

clamp for wire wrapping

Effective wire management is a critical aspect in ensuring optimal performance and longevity of electrical systems. Among the various tools designed to enhance wire management, the clamp for wire wrapping stands out as an essential component. This innovative product doesn't just organize wires, it becomes a linchpin in enhancing system safety and efficiency.

Authoritativeness comes from both the proven performance of high-quality wire wrapping clamps and the reputation of the brands that produce them. Not all clamps are created equal; renowned manufacturers have developed innovative designs that incorporate advanced materials and locking mechanisms, offering superior support and protection. Some leading brands integrate feedback from field technicians and engineers into their product development cycles, continually enhancing the clamp's design to meet evolving industry standards. This iterative process not only underlines a brand's authority in wire management solutions but also ensures the product remains relevant and effective. Moreover, trustworthiness in wire wrapping clamps is derived from stringent testing and quality assurance processes. High-quality clamps are subjected to rigorous stress tests, confirming their ability to withstand various environmental conditions and loads. Professionals rely on products that boast certifications such as UL or CE, ensuring they meet international safety and performance standards. By choosing certified clamps, users can secure their projects with confidence in the product’s adherence to global regulations. Beyond these technical aspects, wire wrapping clamps contribute to sustainability—a core concern in contemporary engineering projects. By preventing wire damage and prolonging the life of electrical components, these clamps minimize waste and promote the efficient use of resources. Furthermore, some manufacturers offer recyclable or eco-friendly clamp options, aligning with the push towards greener engineering solutions. In conclusion, wire wrapping clamps are invaluable across diverse electrical applications. They embody the experience and expertise of seasoned professionals, the authoritativeness of their trusted brands, and the reliability needed for consistent performance. As projects increasingly focus on sustainability and safety, wire wrapping clamps adapt to meet these demands, ensuring wires are organized, secure, and protected, paving the way for efficient, safe, and sustainable systems.

Authoritativeness comes from both the proven performance of high-quality wire wrapping clamps and the reputation of the brands that produce them. Not all clamps are created equal; renowned manufacturers have developed innovative designs that incorporate advanced materials and locking mechanisms, offering superior support and protection. Some leading brands integrate feedback from field technicians and engineers into their product development cycles, continually enhancing the clamp's design to meet evolving industry standards. This iterative process not only underlines a brand's authority in wire management solutions but also ensures the product remains relevant and effective. Moreover, trustworthiness in wire wrapping clamps is derived from stringent testing and quality assurance processes. High-quality clamps are subjected to rigorous stress tests, confirming their ability to withstand various environmental conditions and loads. Professionals rely on products that boast certifications such as UL or CE, ensuring they meet international safety and performance standards. By choosing certified clamps, users can secure their projects with confidence in the product’s adherence to global regulations. Beyond these technical aspects, wire wrapping clamps contribute to sustainability—a core concern in contemporary engineering projects. By preventing wire damage and prolonging the life of electrical components, these clamps minimize waste and promote the efficient use of resources. Furthermore, some manufacturers offer recyclable or eco-friendly clamp options, aligning with the push towards greener engineering solutions. In conclusion, wire wrapping clamps are invaluable across diverse electrical applications. They embody the experience and expertise of seasoned professionals, the authoritativeness of their trusted brands, and the reliability needed for consistent performance. As projects increasingly focus on sustainability and safety, wire wrapping clamps adapt to meet these demands, ensuring wires are organized, secure, and protected, paving the way for efficient, safe, and sustainable systems.

Next:

Latest news

What Are Construction Tools and How Are They Used?

NewsJul.11,2025

Professional-Grade Duct Rodding Tools for Superior Cable Installation

NewsJul.11,2025

Enhancing Safety and Efficiency with Modern Hot Stick Solutions

NewsJul.11,2025

Empowering Cable Installation with Advanced Rodder Solutions

NewsJul.11,2025

Elevate Your Cable Installation Projects with Cable Pulling Tools

NewsJul.11,2025

Efficient Cable Handling Solutions: Cable Rollers for Sale

NewsJul.11,2025

Copyright © 2025 Shijiazhuang Bilo Import and Export Trading Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

BlLo lmport & Éxport is specialized in power and cable equipment andconsiruction tools,Qur main producis are FRP

duct rodder, cable rollerscable pulling winch, cable drum jack, cable pulling sock, etc.

Copyright © 2025 Shijiazhuang Bilo Import and Export Trading Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy