-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Aug . 09, 2024 00:25 Back to list

Choosing the Right Clamp for Proper Ground Rod Installation and Electrical Safety Standards

Understanding Clamps for Ground Rods Essential Components for Electrical Safety

In the realm of electrical installations, grounding systems play a pivotal role in ensuring safety and performance. Among the various components involved in grounding systems, ground rod clamps are critical. These clamps connect ground rods to the grounding conductor, facilitating effective dissipation of electrical currents into the earth and safeguarding electrical systems from potential hazards.

A ground rod, typically made of copper or galvanized steel, is driven into the ground to create a low-resistance path to earth. This is essential for protecting equipment and preventing electrical shock hazards. However, the effectiveness of a ground rod is heavily dependent on its connection to the electrical system, which is where ground rod clamps come into play.

Ground rod clamps are designed to secure the grounding conductor to the ground rod. They are available in various materials and designs to suit different applications and environmental conditions. The choice of clamp material is crucial; common materials include copper, aluminum, and stainless steel, each offering distinct advantages in terms of conductivity, corrosion resistance, and durability.

Types of Ground Rod Clamps

There are several types of ground rod clamps, including

1. Single-Hole Clamps These clamps are designed to attach a single grounding conductor to a ground rod. They are usually easy to install and provide a secure connection, making them a popular choice for many applications.

2. Multi-Hole Clamps For systems requiring multiple grounding conductors to be attached to a single ground rod, multi-hole clamps offer a convenient solution. They can accommodate multiple wires, ensuring the grounding system is robust and efficient.

clamp for ground rod

3. Split-Bolt Clamps These clamps feature a split-bolt design that allows for easy connection and disconnection of wires. They are particularly useful in situations where modifications to the grounding system might be necessary.

4. Compression Clamps Compression clamps must be crimped onto the wire and rod, providing a very secure attachment. Though they require specialized tools for installation, they offer excellent conductivity and corrosion resistance.

Installation Considerations

When installing ground rod clamps, it is essential to follow pertinent electrical codes and regulations. Proper torque specifications should be adhered to when tightening the clamps to ensure that the connection is secure without damaging the components. Excessive force can lead to cracks in the grounding rod, while insufficient force may cause a loose connection, risking system failure.

Additionally, regular inspections and maintenance of ground rod clamps are advisable. Over time, environmental factors such as moisture, temperature changes, and soil conditions can affect the integrity of the connections. Therefore, periodic checks help prevent potential issues before they become critical.

Importance of Ground Connections

The significance of effective ground connections cannot be overstated. A reliable grounding system mitigates risks associated with lightning strikes, power surges, and other electrical faults, providing an essential layer of protection for both equipment and personnel. By using high-quality ground rod clamps and ensuring that they are properly installed and maintained, property owners and electrical engineers alike can enhance the safety and reliability of electrical systems.

In conclusion, ground rod clamps are indispensable components of grounding systems. Their selection and installation are crucial for ensuring effective electrical grounding. As technology and electrical systems evolve, so do the advancements in grounding techniques and materials, underscoring the importance of staying informed about the best practices in electrical safety. By prioritizing the use of reliable ground rod clamps, we can create safer environments for all types of electrical installations.

Latest news

What Are Construction Tools and How Are They Used?

NewsJul.11,2025

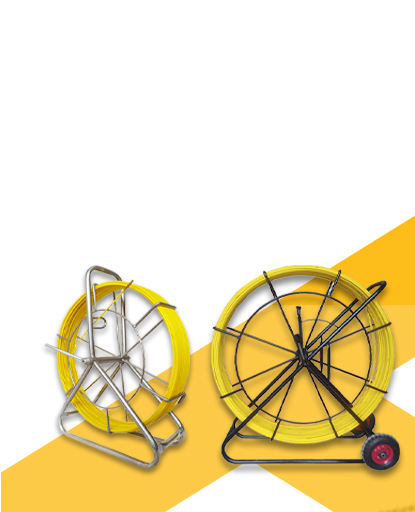

Professional-Grade Duct Rodding Tools for Superior Cable Installation

NewsJul.11,2025

Enhancing Safety and Efficiency with Modern Hot Stick Solutions

NewsJul.11,2025

Empowering Cable Installation with Advanced Rodder Solutions

NewsJul.11,2025

Elevate Your Cable Installation Projects with Cable Pulling Tools

NewsJul.11,2025

Efficient Cable Handling Solutions: Cable Rollers for Sale

NewsJul.11,2025