-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

TEL:

0086-311-88862036

Jan . 14, 2025 16:29 Back to list

Ratchet cable cutting pliers HS-325A

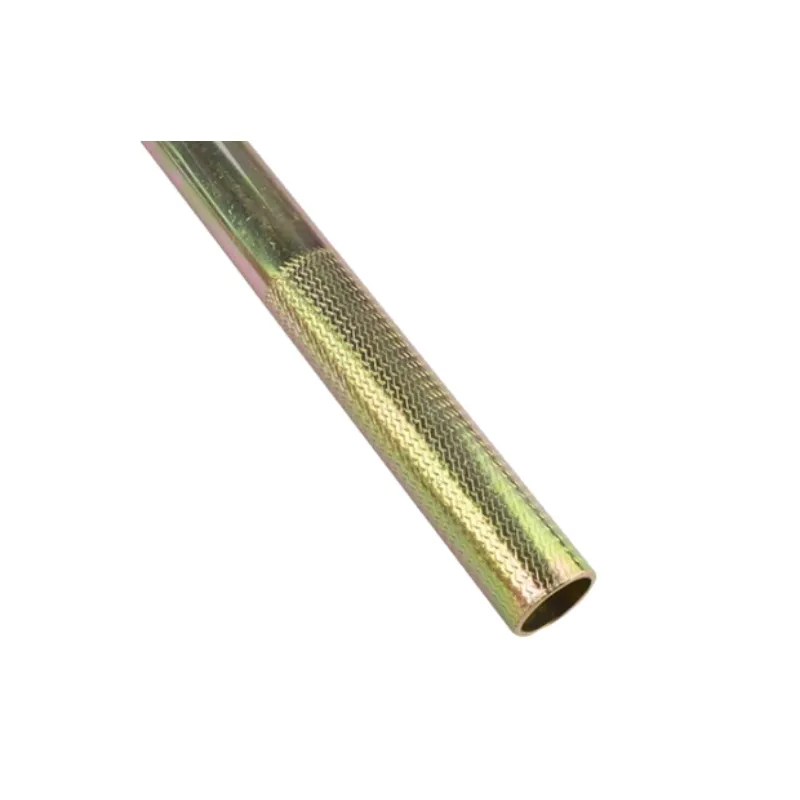

Cable stockings, an essential tool in a variety of industries including telecommunications, electrical engineering, and construction, serve as indispensable aids in the handling of cables and wires. These stockings are intricately designed to hold, support, and protect cables during installation or removal processes. What makes them exceptionally valuable is their ability to manage cables with minimal physical strain, while ensuring durability and preventing potential damage.

Authorities in electrical engineering and telecommunications often endorse cable stockings due to their proven reliability and utility. Case studies and research in professional journals reveal these tools' effectiveness across various applications—from laying underwater cables to intensive industrial setups. Industry-specific training programs emphasize the pivotal role of cable stockings and teach technicians how to incorporate them into their practice without compromising on efficiency or safety standards. For instance, telecom companies deploying vast networks utilize cable stockings extensively as part of their standard operational protocol, underscoring the trust professionals place in these seemingly simple devices. Trustworthiness remains at the core of using cable stockings. For businesses and technicians alike, the stakes are high during any cable installation or maintenance project. By employing cable stockings, they mitigate risks associated with cable handling, such as costly downtime, equipment damage, or safety hazards. The consistent feedback from clients and contractors about the dependability of cable stockings is overwhelmingly positive, reinforcing their status as trustworthy components within any toolkit. Furthermore, leading manufacturers back their cable stockings with warranties and quality guarantees, assuring end-users of their commitment to performance and service. To wrap up, cable stockings embody a fusion of experience, expertise, authority, and trustworthiness. They are critical to the operations of many industries, offering a blend of safety, efficiency, and reliability that is hard to match. As technology and industry demands evolve, the innovations in cable stocking design and material continue to advance, ensuring that they remain a key player in the world of cable management and installation. With proper selection and use, they transform potentially risky cable handling into streamlined, secure processes, making them a staple for any professional involved in cable work.

Authorities in electrical engineering and telecommunications often endorse cable stockings due to their proven reliability and utility. Case studies and research in professional journals reveal these tools' effectiveness across various applications—from laying underwater cables to intensive industrial setups. Industry-specific training programs emphasize the pivotal role of cable stockings and teach technicians how to incorporate them into their practice without compromising on efficiency or safety standards. For instance, telecom companies deploying vast networks utilize cable stockings extensively as part of their standard operational protocol, underscoring the trust professionals place in these seemingly simple devices. Trustworthiness remains at the core of using cable stockings. For businesses and technicians alike, the stakes are high during any cable installation or maintenance project. By employing cable stockings, they mitigate risks associated with cable handling, such as costly downtime, equipment damage, or safety hazards. The consistent feedback from clients and contractors about the dependability of cable stockings is overwhelmingly positive, reinforcing their status as trustworthy components within any toolkit. Furthermore, leading manufacturers back their cable stockings with warranties and quality guarantees, assuring end-users of their commitment to performance and service. To wrap up, cable stockings embody a fusion of experience, expertise, authority, and trustworthiness. They are critical to the operations of many industries, offering a blend of safety, efficiency, and reliability that is hard to match. As technology and industry demands evolve, the innovations in cable stocking design and material continue to advance, ensuring that they remain a key player in the world of cable management and installation. With proper selection and use, they transform potentially risky cable handling into streamlined, secure processes, making them a staple for any professional involved in cable work.

Latest news

What Are Construction Tools and How Are They Used?

NewsJul.11,2025

Professional-Grade Duct Rodding Tools for Superior Cable Installation

NewsJul.11,2025

Enhancing Safety and Efficiency with Modern Hot Stick Solutions

NewsJul.11,2025

Empowering Cable Installation with Advanced Rodder Solutions

NewsJul.11,2025

Elevate Your Cable Installation Projects with Cable Pulling Tools

NewsJul.11,2025

Efficient Cable Handling Solutions: Cable Rollers for Sale

NewsJul.11,2025

Copyright © 2025 Shijiazhuang Bilo Import and Export Trading Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

BlLo lmport & Éxport is specialized in power and cable equipment andconsiruction tools,Qur main producis are FRP

duct rodder, cable rollerscable pulling winch, cable drum jack, cable pulling sock, etc.

Copyright © 2025 Shijiazhuang Bilo Import and Export Trading Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy