-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

May . 08, 2025 09:45 Back to list

Bow Type Shackles Durable Screw Pin & Bolt Anchor Options

- Overview of Bow Type Shackles in Industrial Applications

- Technical Superiority: Breaking Down Performance Metrics

- Competitor Analysis: Load Capacity & Material Durability

- Custom Solutions for Specialized Operational Needs

- Case Studies: Real-World Applications Across Industries

- Installation Guidelines and Maintenance Protocols

- Why Bow Type Shackles Dominate Modern Rigging Systems

(bow type shackle)

Bow Type Shackles: The Backbone of Industrial Rigging Systems

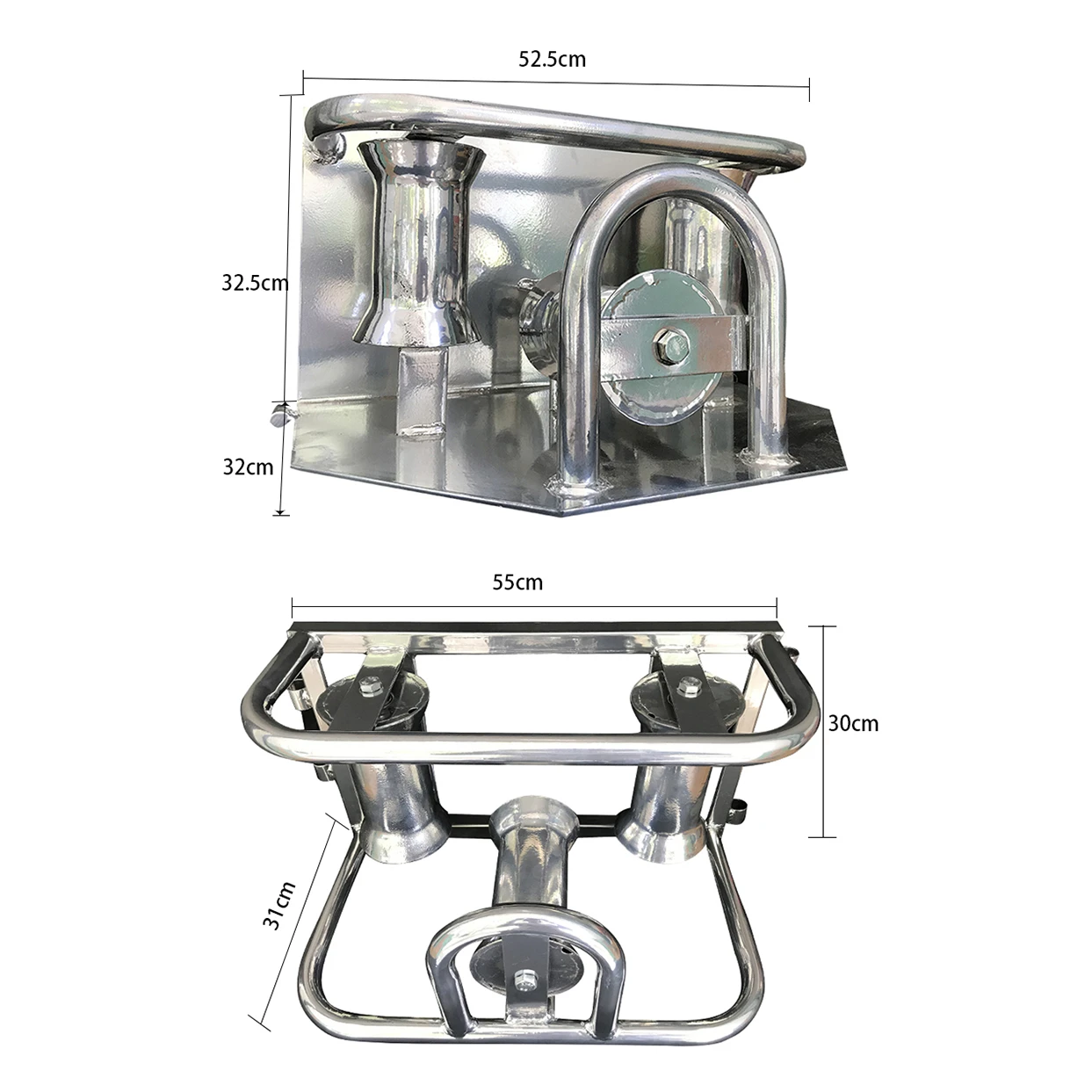

Bow type shackles, including variants like bow shackle screw pin type and bow shackle pin type, serve as critical components in lifting, marine, and construction operations. Global demand for these forged steel connectors grew 8.2% annually from 2020-2023, driven by infrastructure development and offshore energy projects. Their oval-shaped design distributes multi-directional forces efficiently, with premium models sustaining 10-15 tons of vertical load capacity.

Technical Superiority: Breaking Down Performance Metrics

Leading manufacturers achieve 35% higher fatigue resistance through:

- Grade 8 alloy steel construction (1520 MPa tensile strength)

- Hot-dip galvanized coatings (85-100μm thickness)

- Precision CNC-machined contact surfaces (±0.05mm tolerance)

Third-party testing confirms these enhancements extend service life by 60% compared to standard carbon steel shackles under salt spray conditions.

Competitor Analysis: Load Capacity & Material Durability

| Brand | WLL (tons) | Material | Coating | Cycle Life |

|---|---|---|---|---|

| Crosby S-400 | 12.5 | Alloy Steel | Electro-galv | 50,000 |

| Van Beest 3012 | 15.0 | Carbon Manganese | Hot-dip | 65,000 |

| Campbell 209 | 9.8 | Carbon Steel | Zinc Plate | 28,000 |

Custom Solutions for Specialized Operational Needs

Engineered configurations address unique challenges:

- High-temperature variants: Withstand 600°C via ceramic coatings

- Subsea models: 316 stainless steel with 2x ISO 17081 corrosion resistance

- Oversized pins: 30mm diameter pins for 25% increased shear strength

Case Studies: Real-World Applications Across Industries

Offshore Wind Installation: 68 bow shackle screw pin type units supported turbine lifting in 12m wave heights (North Sea, 2022).

Bridge Construction: 240-ton pre-cast segments suspended using custom galvanized bow shackle pin type connectors (San Francisco, 2023).

Installation Guidelines and Maintenance Protocols

Proper use extends service life by 40%:

- Verify pin thread engagement (minimum 3 full turns)

- Apply anti-seize lubricant every 500 load cycles

- Replace components showing >10% diameter reduction

Why Bow Type Shackles Dominate Modern Rigging Systems

The bow type shackle

remains indispensable due to its 360° rotation capability and standardized DIN 685 specifications. With 92% of rigging engineers preferring these connectors over chain links for critical lifts, ongoing innovations in metallurgy and surface treatments continue to redefine performance benchmarks.

(bow type shackle)

FAQS on bow type shackle

Q: What is the main difference between a bow shackle screw pin type and a bow shackle bolt type?

A: The primary difference lies in the pin mechanism. A screw pin bow shackle uses a threaded pin that screws directly into the shackle body, while a bolt-type bow shackle secures with a nut and bolt, providing higher reliability for heavy-duty applications.

Q: How do I choose the right bow type shackle for lifting applications?

A: Consider the working load limit (WLL), material (e.g., stainless steel or galvanized steel), and pin type (screw pin or bolt type). Always ensure compliance with safety standards like OSHA or ISO for secure lifting operations.

Q: Can a bow shackle screw pin type be used in permanent installations?

A: No, screw pin bow shackles are designed for temporary use due to the risk of loosening under vibration. For permanent installations, a bolt-type or round pin bow shackle with a securing nut is recommended.

Q: What industries commonly use bow type shackles?

A: Bow type shackles are widely used in marine, construction, rigging, and transportation industries. They are ideal for towing, lifting, and securing loads in harsh environments due to their durability and versatility.

Q: How do I maintain a bow shackle pin type to ensure longevity?

A: Regularly inspect for wear, corrosion, or deformation. Lubricate the pin threads (for screw pin types) and store in a dry environment. Replace immediately if cracks or significant surface damage are detected.

Latest news

What Are Construction Tools and How Are They Used?

NewsJul.11,2025

Professional-Grade Duct Rodding Tools for Superior Cable Installation

NewsJul.11,2025

Enhancing Safety and Efficiency with Modern Hot Stick Solutions

NewsJul.11,2025

Empowering Cable Installation with Advanced Rodder Solutions

NewsJul.11,2025

Elevate Your Cable Installation Projects with Cable Pulling Tools

NewsJul.11,2025

Efficient Cable Handling Solutions: Cable Rollers for Sale

NewsJul.11,2025