-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

TEL:

0086-311-88862036

Jan . 20, 2025 00:19 Back to list

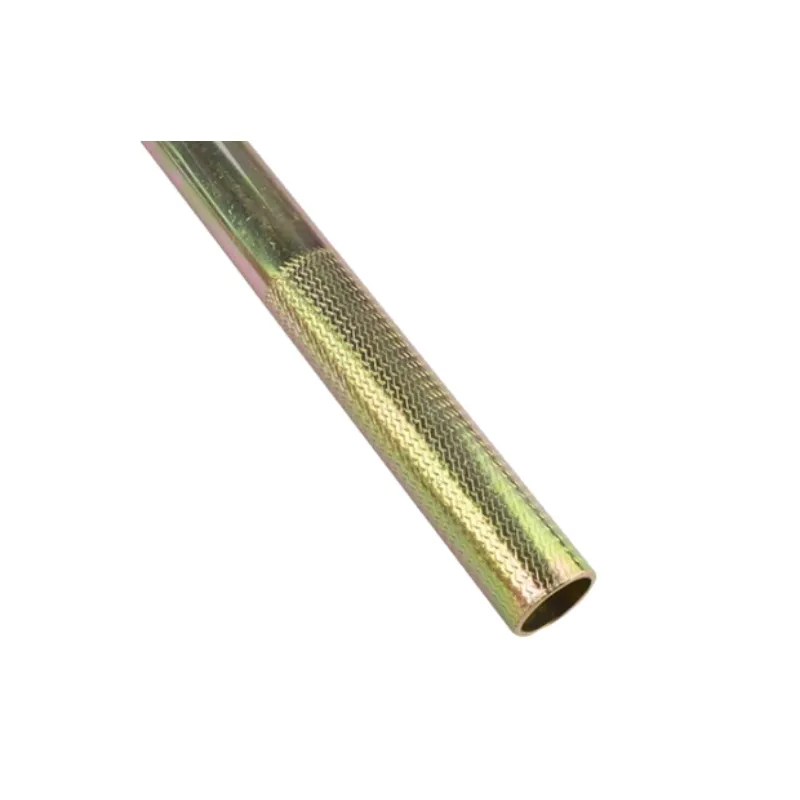

aerial cable clamp

Aerial cable clamps, those unsung heroes of electrical and telecommunications infrastructure, play an indispensable role in supporting overhead power lines and communication cables crisscrossing our landscapes. Yet, for a product so crucial, the intricate details and expertise behind its design and manufacturing often receive less attention than they deserve. Delving deeper into the world of aerial cable clamps reveals an arena of innovation, precision, and authority in material sciences and engineering.

Field experience from seasoned professionals underscores the importance of proper installation and maintenance of aerial cable clamps. While the design and materials of the clamps themselves are crucial, so too is the expertise of the technicians who install them. Proper tensioning, alignment, and securing of clamps can significantly extend the lifespan of the cables they support. Regular inspections ensure that the infrastructure remains in optimal condition, identifying potential issues before they escalate into costly repairs or outages. In discussing aerial cable clamps, one cannot overlook the technological advancements making waves in the industry. Smart clamps are an emerging innovation, equipped with sensors to monitor real-time data such as temperature and tension. These advancements allow for predictive maintenance, effectively minimizing downtime and enhancing the reliability of energy and data transmission networks. As the infrastructure supporting global communication and power distribution becomes increasingly complex, the role of aerial cable clamps continues to grow. These components, though small, are vital cogs in a massive machine, ensuring uninterrupted service and safety. Thus, investing in high-quality aerial cable clamps backed by robust research, expert design, and authoritative testing not only fulfills an operational necessity but also represents a commitment to reliability and excellence in infrastructural development. In conclusion, aerial cable clamps exemplify a marriage of innovation and practicality where precision engineering meets field-tested reliability. Their evolution reflects an ongoing commitment to enhance the efficacy of global infrastructures, reinforcing the importance of expertise and trustworthiness in the products that uphold our modern world.

Field experience from seasoned professionals underscores the importance of proper installation and maintenance of aerial cable clamps. While the design and materials of the clamps themselves are crucial, so too is the expertise of the technicians who install them. Proper tensioning, alignment, and securing of clamps can significantly extend the lifespan of the cables they support. Regular inspections ensure that the infrastructure remains in optimal condition, identifying potential issues before they escalate into costly repairs or outages. In discussing aerial cable clamps, one cannot overlook the technological advancements making waves in the industry. Smart clamps are an emerging innovation, equipped with sensors to monitor real-time data such as temperature and tension. These advancements allow for predictive maintenance, effectively minimizing downtime and enhancing the reliability of energy and data transmission networks. As the infrastructure supporting global communication and power distribution becomes increasingly complex, the role of aerial cable clamps continues to grow. These components, though small, are vital cogs in a massive machine, ensuring uninterrupted service and safety. Thus, investing in high-quality aerial cable clamps backed by robust research, expert design, and authoritative testing not only fulfills an operational necessity but also represents a commitment to reliability and excellence in infrastructural development. In conclusion, aerial cable clamps exemplify a marriage of innovation and practicality where precision engineering meets field-tested reliability. Their evolution reflects an ongoing commitment to enhance the efficacy of global infrastructures, reinforcing the importance of expertise and trustworthiness in the products that uphold our modern world.

Latest news

What Are Construction Tools and How Are They Used?

NewsJul.11,2025

Professional-Grade Duct Rodding Tools for Superior Cable Installation

NewsJul.11,2025

Enhancing Safety and Efficiency with Modern Hot Stick Solutions

NewsJul.11,2025

Empowering Cable Installation with Advanced Rodder Solutions

NewsJul.11,2025

Elevate Your Cable Installation Projects with Cable Pulling Tools

NewsJul.11,2025

Efficient Cable Handling Solutions: Cable Rollers for Sale

NewsJul.11,2025

Copyright © 2025 Shijiazhuang Bilo Import and Export Trading Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

BlLo lmport & Éxport is specialized in power and cable equipment andconsiruction tools,Qur main producis are FRP

duct rodder, cable rollerscable pulling winch, cable drum jack, cable pulling sock, etc.

Copyright © 2025 Shijiazhuang Bilo Import and Export Trading Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy