-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Nov . 09, 2024 03:32 Back to list

Selecting the Right 35mm Earth Cable for Your Electrical Projects

Understanding 35mm² Earth Cable Specifications, Applications, and Importance

When it comes to electrical installations, particularly in commercial and industrial sectors, grounding or earthing is a critical aspect that cannot be overlooked. One of the prominent types of cables used for earthing purposes is the 35mm² earth cable. This article delves into the specifications, applications, and significance of 35mm² earth cable in modern electrical systems.

Specifications of 35mm² Earth Cable

The term 35mm² refers to the cross-sectional area of the cable's conductor, which is 35 square millimeters. This measurement is vital as it directly correlates with the amount of current the cable can safely carry. In the case of a 35mm² earth cable, it is typically manufactured using copper or aluminum conductors, with copper being preferred for its superior conductivity and corrosion resistance.

The insulation material used in 35mm² earth cables also plays a key role in ensuring safety and durability. Common insulators include PVC (Polyvinyl Chloride), XLPE (Cross-Linked Polyethylene), or even rubber for specialized applications. These materials provide protection against environmental factors and mechanical stress while maintaining high dielectric strength.

Moreover, the cable is often designed to comply with international and local standards, such as the IEC (International Electrotechnical Commission) or BS (British Standard) regulations. These standards ensure that the cable performs safely and efficiently under various operating conditions.

Applications of 35mm² Earth Cable

35mm² earth cables have a wide array of applications, primarily related to grounding systems in electrical installations. Here are some key areas where these cables are utilized

1. Industrial Installations In factories and manufacturing plants, robust earthing systems are essential to protect equipment and personnel from electrical faults. A 35mm² earth cable can handle large fault currents, ensuring that any stray electricity is safely directed to the ground, reducing the risk of electric shocks and equipment damage.

2. Commercial Buildings In office complexes and retail spaces, effective grounding is necessary to prevent voltage surges that could disrupt electronic devices. The use of 35mm² earth cables in these settings ensures reliable protection against lightning strikes and other electrical surges.

35mm earth cable

3. Renewable Energy Systems As the world moves towards cleaner energy sources, grounding becomes increasingly crucial in solar and wind power systems. A 35mm² earth cable is often used to ground the structural framework of solar panels and wind turbines, ensuring operational safety and performance reliability.

4. Telecommunications Telecommunication infrastructures, including cell towers and data centers, require earthing for the protection of sensitive electronic equipment. The robustness of a 35mm² earth cable makes it ideal for these applications, where susceptibility to transient voltage spikes is a concern.

Importance of 35mm² Earth Cable

The importance of using a 35mm² earth cable in electrical installations cannot be overstated. A well-designed earthing system

- Enhances Safety By adequately grounding equipment, the risk of electric shock to personnel is significantly reduced. This is particularly critical in environments where workers are exposed to potentially hazardous electrical conditions.

- Protects Equipment A reliable earthing system minimizes the risk of damage to electrical appliances and machines from fault currents and voltage surges. This, in turn, leads to lower maintenance costs and extended equipment lifespan.

- Ensures Compliance Adhering to electrical standards and regulations helps avoid legal liabilities and ensures that installations meet safety and performance criteria.

- Facilitates Efficiency Proper grounding can improve the overall efficiency of electrical systems by providing a stable reference point for voltages, allowing equipment to operate optimally.

In conclusion, the 35mm² earth cable is a vital component in electrical installations, serving multiple roles that enhance safety, protect equipment, and ensure compliance with regulatory standards. As technology evolves and the complexity of electrical systems increases, the significance of such grounding solutions will only continue to grow, making them cornerstone elements in any safe and reliable electrical infrastructure.

Latest news

What Are Construction Tools and How Are They Used?

NewsJul.11,2025

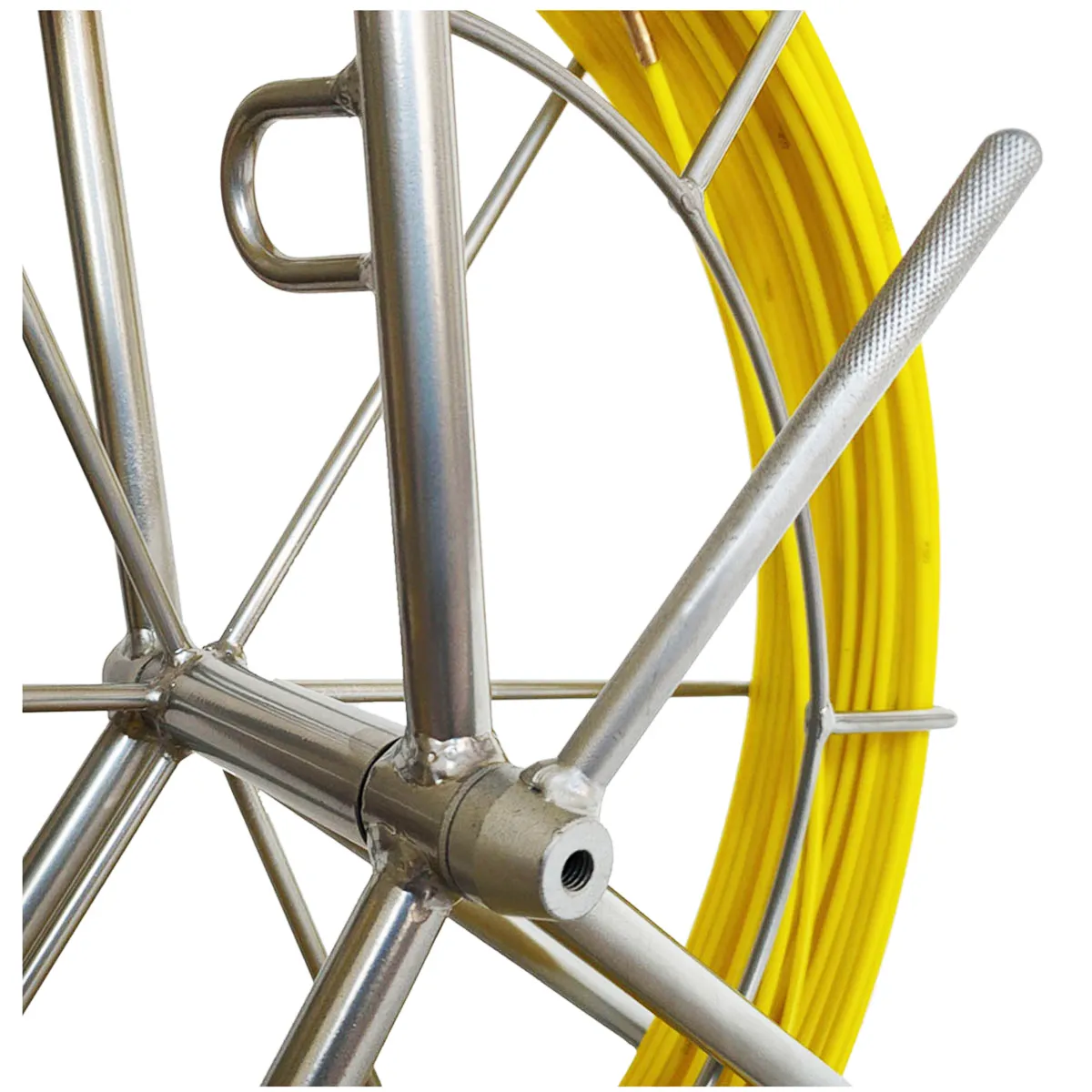

Professional-Grade Duct Rodding Tools for Superior Cable Installation

NewsJul.11,2025

Enhancing Safety and Efficiency with Modern Hot Stick Solutions

NewsJul.11,2025

Empowering Cable Installation with Advanced Rodder Solutions

NewsJul.11,2025

Elevate Your Cable Installation Projects with Cable Pulling Tools

NewsJul.11,2025

Efficient Cable Handling Solutions: Cable Rollers for Sale

NewsJul.11,2025