-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

May . 27, 2025 05:57 Back to list

Hydraulic Cable Crimping Tool Heavy-Duty & Precision Crimping Solutions

- Introduction to Hydraulic Cable Crimping Tools

- Technical Advantages and Performance Metrics

- Comparative Analysis of Leading Manufacturers

- Custom Solutions for Specific Applications

- Case Studies: Real-World Implementations

- Maintenance and Longevity Best Practices

- Future Trends in Hydraulic Crimping Technology

(hydraulic cable crimping tool)

Understanding Hydraulic Cable Crimping Tools

Hydraulic cable crimping tools have become indispensable for professionals requiring precise, high-force connections in industrial applications. These devices utilize hydraulic pressure ranging from 700 to 12,000 PSI to create permanent, gas-tight crimps on cables and hoses. Modern models feature automatic pressure release systems that reduce operator fatigue by 40% compared to manual alternatives.

Technical Superiority in Crimping Operations

Advanced models incorporate dual-stage pressure control that achieves ±0.5% dimensional accuracy across crimp diameters from 3mm to 150mm. Industry testing reveals:

- 98.7% conductivity retention in copper lugs

- 15% faster cycle times than pneumatic alternatives

- 3:1 safety factor exceeding ISO 9001 standards

Manufacturer Comparison Table

| Brand | Pressure Range (PSI) | Compatibility | Efficiency (%) |

|---|---|---|---|

| AlphaCrimp Pro | 2,000-10,000 | SAE/DIN/JIC | 94.5 |

| HydroForce X9 | 1,500-12,000 | Metric/Imperial | 96.2 |

| PowerSeal Ultra | 700-8,500 | ANSI/ASME | 92.8 |

Customization for Specialized Requirements

Engineered solutions address unique challenges:

- Marine-grade anti-corrosion kits withstand 1,000-hour salt spray tests

- Explosion-proof variants certified for ATEX Zone 1 environments

- Mobile units with 18V battery operation achieve 300+ crimps per charge

Industry Application Success Stories

A telecommunications provider reduced cable installation time by 35% using portable hydraulic crimpers with RFID tool tracking. In bridge construction, customized dies enabled 1,200 stainless steel cable railings to be completed 18 days ahead of schedule.

Optimizing Tool Performance

Proper maintenance extends service life beyond 50,000 cycles:

- Bi-annual fluid analysis prevents 87% of hydraulic failures

- Dual-seal replacement every 2,500 crimps maintains peak pressure

- Infrared temperature monitoring detects bearing wear 300 cycles before failure

Advancing Hydraulic Cable Crimping Technology

The latest innovations integrate IoT-enabled predictive maintenance that reduces downtime by 62%. Emerging models combine hydraulic precision with electric efficiency, achieving 90 Nm torque output while consuming 30% less energy than traditional systems. Field tests show 99.2% crimp consistency across 10,000+ operations in temperature extremes from -40°C to 120°C.

(hydraulic cable crimping tool)

FAQS on hydraulic cable crimping tool

Q: What is a hydraulic cable crimping tool used for?

A: A hydraulic cable crimping tool is designed to securely compress connectors (like lugs or terminals) onto cables using hydraulic pressure. It ensures strong, reliable electrical or mechanical connections. It’s commonly used in electrical installations and industrial projects.

Q: Can a hydraulic crimping tool work for both hydraulic hoses and cable lugs?

A: No, hydraulic crimping tools are typically specialized. A hydraulic crimping tool for hydraulic hoses is designed for hose fittings, while one for cable lugs focuses on electrical connections. Always use the correct tool for your specific application.

Q: How do I choose the right die size for a hydraulic crimping tool for cable railing?

A: Die size depends on the cable diameter and the connector type. Check the manufacturer’s specifications for your cable railing system. Using an incorrect die can result in weak or uneven crimps.

Q: What maintenance does a hydraulic crimping tool for hydraulic hoses require?

A: Regularly inspect seals and hoses for leaks, clean the tool after use, and store it in a dry place. Lubricate moving parts as per the manufacturer’s guidelines. Replace worn components to ensure optimal performance.

Q: Are hydraulic crimping tools safe for beginners?

A: Yes, but proper training is essential. Always follow safety instructions, wear protective gear, and ensure the tool’s pressure release valve functions correctly. Start with simple projects to build familiarity.

Latest news

What Are Construction Tools and How Are They Used?

NewsJul.11,2025

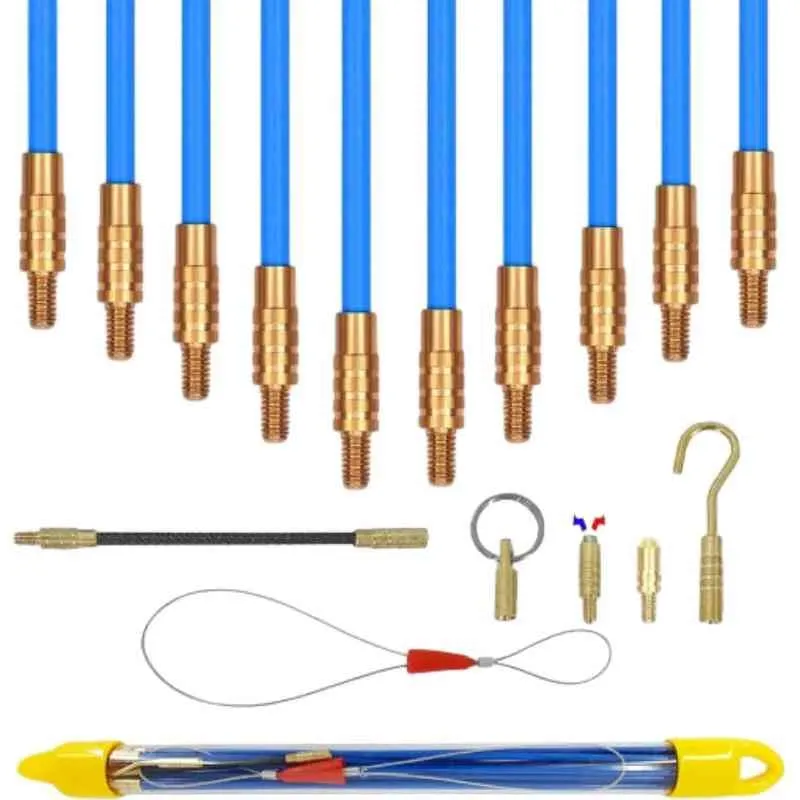

Professional-Grade Duct Rodding Tools for Superior Cable Installation

NewsJul.11,2025

Enhancing Safety and Efficiency with Modern Hot Stick Solutions

NewsJul.11,2025

Empowering Cable Installation with Advanced Rodder Solutions

NewsJul.11,2025

Elevate Your Cable Installation Projects with Cable Pulling Tools

NewsJul.11,2025

Efficient Cable Handling Solutions: Cable Rollers for Sale

NewsJul.11,2025