-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

12-р сар . 10, 2024 10:06 Back to list

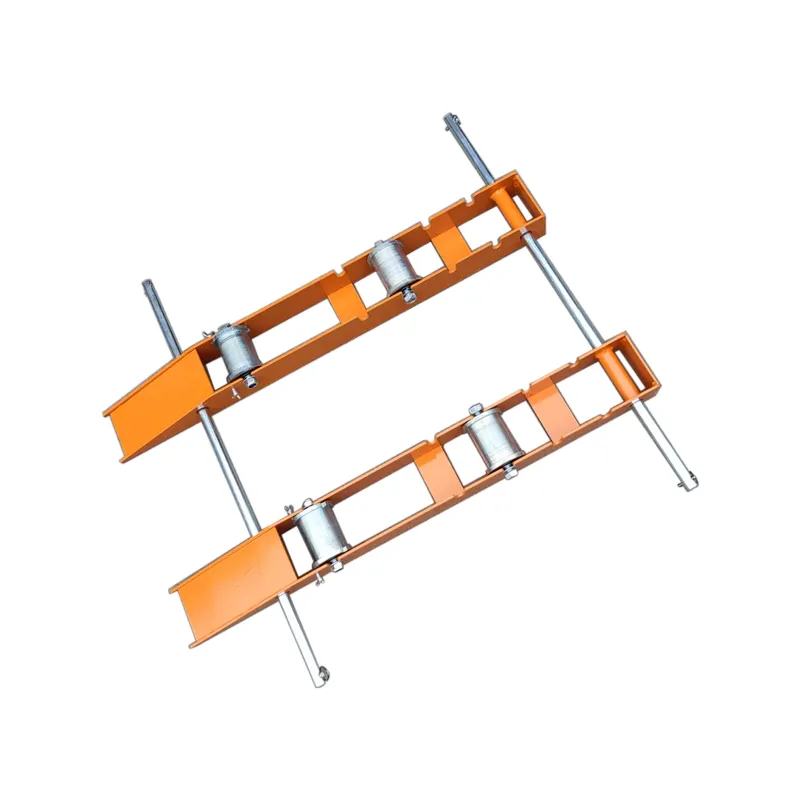

clamp grounding rod

Understanding Clamp Grounding Rods Essential Components for Electrical Safety

In the world of electrical engineering and safety, grounding is a critical aspect that often goes unnoticed until a problem arises. One of the key components in ensuring effective grounding is the clamp grounding rod. This article delves into the significance of clamp grounding rods, their functions, installation processes, and maintenance tips to ensure the safety and efficiency of electrical systems.

What is a Clamp Grounding Rod?

A clamp grounding rod is a metal rod, usually made of copper or galvanized steel, that is driven into the ground to serve as a grounding point for electrical systems. The main purpose of grounding is to provide a safe path for excess electrical currents, such as those caused by lightning strikes or equipment faults. By connecting electrical systems to the grounding rod, operators can prevent dangerous electrical shocks, damage to equipment, and fire hazards.

Importance of Grounding

Grounding is not just a regulatory requirement; it is a fundamental aspect of electrical safety. With proper grounding, the likelihood of electrical shock or equipment damage is greatly minimized. In industrial settings, grounding ensures that sensitive equipment operates correctly and isn't subjected to harmful surges. Additionally, grounding helps stabilize voltage levels within electrical systems, thereby improving the overall efficiency and longevity of electrical installations.

Components of a Clamp Grounding Rod

The clamp grounding rod system typically consists of three main components the grounding rod itself, the grounding clamp, and the grounding wire.

1. Grounding Rod The rod is the first line of defense. Its length and material affect its conductive properties and resistance to corrosion. Standard lengths vary, but a common length is between 8 to 10 feet, which ensures sufficient penetration into the earth to achieve effective grounding.

2. Grounding Clamp This component secures the grounding wire to the grounding rod. It should be made of corrosion-resistant materials to ensure longevity and reliability. The clamp must be tightly fastened to promote effective electrical conductivity.

3. Grounding Wire This wire connects the grounding rod to electrical equipment. Typically made from copper or aluminum, the wire must be appropriately sized to handle potential fault currents without overheating.

clamp grounding rod

Installation Process

The installation of a clamp grounding rod is a straightforward process, but several key steps must be observed for optimal performance.

1. Site Selection Choose a location that is free from interference, such as large trees and buildings, which can impede effective grounding.

2. Driving the Rod The rod is typically driven into the ground using a hammer or a grounding rod driver. It should penetrate at least 8 feet into the earth to ensure proper conductivity.

3. Attaching the Clamp Once the rod is in place, the grounding clamp must be attached securely at a point above ground to ensure easy access for maintenance.

4. Connecting the Wire Finally, the grounding wire is connected from the clamp to the electrical components that require grounding. Proper connection is crucial, so ensure that all connections are secure and weatherproof.

Maintenance and Inspection

Regular maintenance of grounding systems is crucial for electrical safety. Inspect the grounding rod and connections at least once a year, particularly after severe weather events. Look for signs of corrosion, loose clamps, or breaks in the wire. Testing the resistance of the grounding system using a ground resistance tester is also recommended to ensure it meets the safety standards.

If you notice any issues during your inspection, it is best to address them immediately to maintain the integrity of your grounding system.

Conclusion

Clamp grounding rods are indispensable tools in safeguarding electrical systems from faults that can potentially cause harm. Their installation and maintenance are crucial for ensuring the safety of both people and equipment. By understanding the importance and functionality of these grounding systems, individuals and organizations can enhance their electrical safety protocols and compliance with industry standards. As technology continues to advance, grounding techniques and systems will evolve, but the fundamental necessity for reliable grounding will remain constant. Always prioritize safety and stay informed about the best practices in electrical grounding.

Latest news

duct-rodders-and-conduit-rod-tools

NewsAug.22,2025

ratchet-pullers-and-wire-tightening-tools

NewsAug.22,2025

chain-ratchet-pullers-and-hoist-solutions

NewsAug.22,2025

telescopic-hot-stick-for-electrical-and-high-voltage-use

NewsAug.22,2025

cable-clamp-and-insulated-cable-clamp-systems

NewsAug.22,2025

duct-rodder-conduit-rodder-and-cable-solutions

NewsAug.22,2025