-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

تەموز . 21, 2025 12:01 Back to list

Best Cable Pulling Tools: High-Performance & Durable Solutions for Pros

As technological advancements continue to reshape industries, cable pulling tools have emerged as critical components in modern electrical and telecommunications infrastructure projects. These specialized tools not only enhance efficiency but also significantly reduce installation time and labor costs. From large-scale industrial projects to residential installations, choosing the appropriate cable pulling equipment is essential for any successful cable deployment operation.

Phone: 0086-311-88862036

Email: info@bilopowtel.com

Mobile: 008615226563165

Website: www.bilopowtel.com

Fundamentals of Cable Pulling Systems

Understanding the physics and mechanics of cable installation helps professionals select the right tools for their specific application. Cable pulling systems typically incorporate several components working in concert: power sources, tension control mechanisms, cable guidance systems, and protective elements. When properly coordinated, these cable pulling tools allow cables to be installed efficiently through conduits, cable trays, and other pathways with minimal stress on the conductors.

The industry has evolved significantly since the early days of manual pulling methods. Today, specialized tools like the cable pulling winch provide controlled mechanical advantage, allowing installers to pull thousands of feet of heavy cable with minimal effort. Simultaneously, innovations such as cable tray rollers ensure smooth movement through support systems, significantly reducing friction and preventing damage to cable jackets.

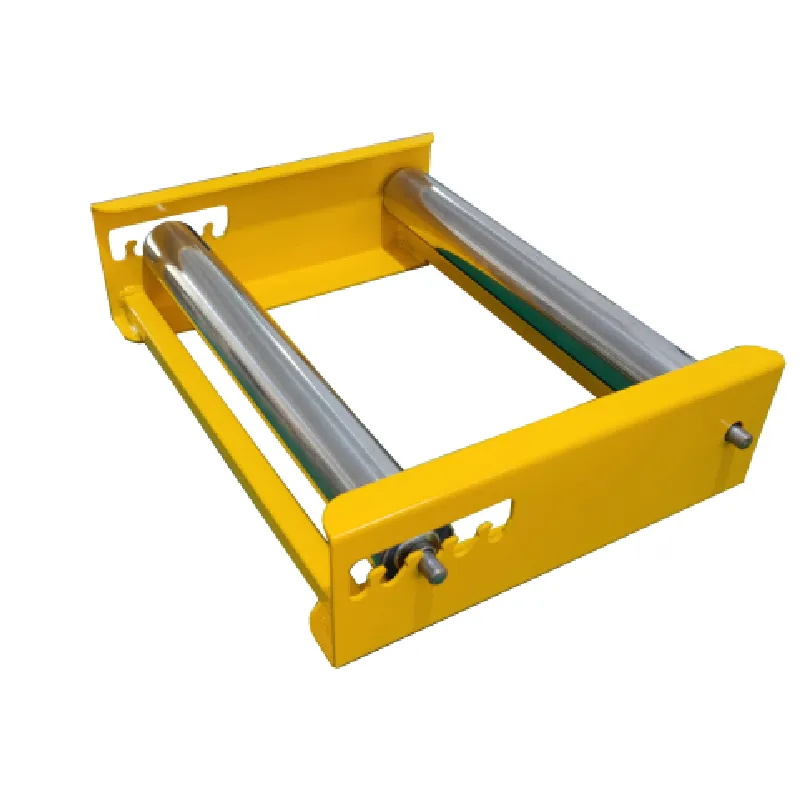

Cable Drum Roller Dispenser: Essential Equipment

As featured equipment from Shijiazhuang Bilo, the Cable Drum Roller Dispenser plays a pivotal role in modern cable installation projects. This sophisticated device provides critical support and stabilization for cable drums during deployment operations, ensuring smooth and controlled cable payout regardless of cable weight or length.

Technical Advantages

Engineered for heavy-duty applications, the dispenser features a robust structural design combined with precision-balanced rollers that minimize rotational resistance. The adjustable brake system offers precise tension control, preventing cable overrun and tangling during deployment. This capability is particularly valuable when working with premium cable products where surface protection is paramount.

Operational Efficiency

Significantly reducing manual handling requirements, this dispenser allows a single operator to control large cable deployments that previously required entire teams. Its compatibility with various drum sizes and cable types makes it versatile across numerous applications, from industrial power cables to sophisticated fiber optic installations.

Cable Pulling Equipment Technical Specifications

The performance metrics of cable pulling equipment directly impact project planning and execution. Understanding capacity ratings, power requirements, and compatibility specifications is essential for selecting appropriate tools for specific installation environments.

| Equipment Type | Max Capacity (lbs) | Power Source | Cable Diameter Range | Typical Applications |

|---|---|---|---|---|

| Cable Pulling Winch | 10,000 | Hydraulic/Electric | 0.5-4 inches | Industrial power, Sub-stations |

| Cable Pulling Sock | 5,000 | Manual | 0.25-2 inches | Commercial buildings, Residential |

| Cable Tray Rollers | N/A | Passive | Unlimited | Cable tray installations |

| Cable Drum Dispenser | 15,000 | Mechanical | 0.25-5 inches | All cable deployment scenarios |

| Conduit Rodder | 1,500 | Manual/Electric | Up to 4 inch conduits | Underground installations |

ECharts: Cable Pulling Tools Market Analysis

Cable Pulling Tools in Specialized Applications

The evolution of cable pulling tools continues to address increasingly complex installation challenges across diverse sectors:

1. Renewable Energy Installations

Wind and solar farms require specialized cable pulling equipment capable of managing lengthy runs of high-voltage conductors in challenging outdoor conditions. Corrosion-resistant materials and sealed components ensure long-term reliability in these demanding environments.

2. Data Center Infrastructure

Modern data centers utilize high-density fiber pathways that demand precise cable tray rollers and specialized pull grips that prevent damage to fragile optical fibers. Installation speed and accuracy are paramount in these high-value facilities.

3. Urban Utility Networks

Underground cable installations in congested urban areas require sophisticated horizontal directional drilling equipment combined with specialized pulling socks that protect conductors during installation through existing conduit networks.

Technical FAQ: Cable Pulling Equipment

Industry References & Authoritative Research

The following research articles and industry publications provide valuable insights into cable pulling technologies:

Optimize Your Cable Installation Operations

Discover advanced cable pulling solutions including our premium Cable Drum Roller Dispenser designed for demanding industrial applications. Visit our product page to explore complete specifications and technical documentation:

Conclusion: The Future of Cable Pulling Technology

The future of cable pulling tools lies in continued integration with digital technologies. AI-assisted tension control systems, automated lubrication application, and smart path mapping algorithms represent the next evolutionary step for professional cable installation equipment. As global infrastructure expands, innovations in cable pulling equipment will play an increasingly vital role in efficiently connecting power and data networks worldwide.

Companies like Shijiazhuang Bilo Import and Export Trading Co., Ltd. continue to advance cable deployment technology, with products like their Cable Drum Roller Dispenser setting new industry standards for reliability and efficiency. As installation challenges grow increasingly complex, specialized cable pulling tools become not just advantageous but essential components of successful electrical construction projects.

Further industry insight can be found in these additional resources:

Latest news

What Are Construction Tools and How Are They Used?

NewsJul.11,2025

Professional-Grade Duct Rodding Tools for Superior Cable Installation

NewsJul.11,2025

Enhancing Safety and Efficiency with Modern Hot Stick Solutions

NewsJul.11,2025

Empowering Cable Installation with Advanced Rodder Solutions

NewsJul.11,2025

Elevate Your Cable Installation Projects with Cable Pulling Tools

NewsJul.11,2025

Efficient Cable Handling Solutions: Cable Rollers for Sale

NewsJul.11,2025