-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

11월 . 01, 2024 19:58 Back to list

A Comprehensive Guide to Wire Pulling Techniques Using a Sling for Strategic Success

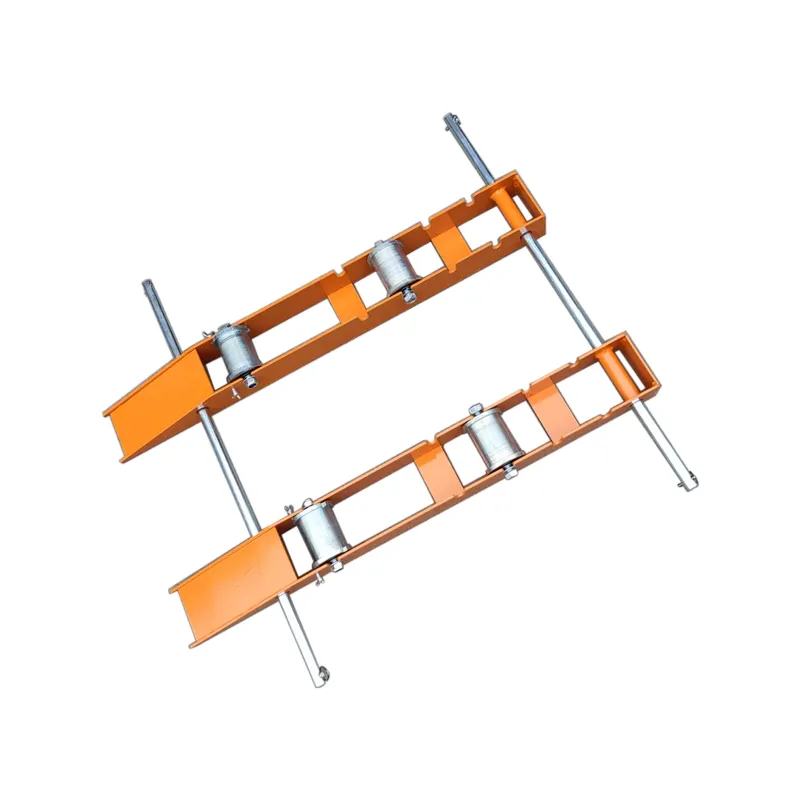

Wire Pulling with a Sling A Strategic Guide

Wire pulling is an essential task in many construction and electrical projects. Using a sling to assist with this process can enhance efficiency and safety, ultimately leading to a more effective workflow. This article serves as a strategic guide to wire pulling with a sling, outlining the best practices and techniques to ensure a successful operation.

First and foremost, understanding the fundamentals of wire pulling is crucial. The objective is to maneuver electrical wires through conduits or channels while minimizing damage and ensuring a smooth installation. A sling can significantly aid this process by distributing the pulling force evenly, reducing the strain on both the wire and the installation team.

Selecting the Right Sling

The first step in wire pulling with a sling is selecting the appropriate equipment. Slings come in various types, including nylon, polyester, and rope slings, with differing capacities and stretching characteristics. It’s imperative to choose a sling that is rated for the specific load you will be pulling, considering both the weight of the wire and the conditions of the installation site. Always refer to manufacturer guidelines and safety data sheets to ensure compliance and safety.

Preparing the Worksite

Before initiating any wire pulling task, proper preparation of the worksite is essential. Clear the area of debris, obstacles, and any other hazards that may impede the operation. Ensure that the path where the wire will be pulled is free from sharp edges or pinch points that could damage the wire insulation. Establish a clear communication protocol among team members to coordinate the pulling process efficiently.

wire pulling with a sling a strategic guide

Using the Sling Effectively

Once the sling and site are prepared, it’s time to begin the wire pulling process. The sling should be securely attached to both the wire and the pulling mechanism (such as a winch or a manual pulling tool). This attachment must be firm enough to withstand the pulling force without slipping. Adjust the angle of the sling as needed to ensure an even pull, which helps avoid stress points on the wire.

During the pulling process, it’s critical to maintain a steady and controlled force. Avoid sudden jerks or excessive force that could overwhelm the cables and potentially lead to damage. Team members should work in unison, as synchronized pulling can prevent snags and ensure a seamless installation.

Post-Pulling Checklist

After completing the wire pulling, perform a thorough inspection of the wire and sling. Ensure there are no signs of damage, kinks, or abrasions on the wire insulation. Check the sling for any wear or deterioration that may compromise its integrity in future tasks. Proper documentation of the installation process and any issues encountered can aid in future projects and provide valuable insights for improvement.

Conclusion

Wire pulling with a sling is a strategic operation that, when executed properly, enhances the efficiency and safety of electrical installations. By selecting the right equipment, preparing the worksite, and employing effective techniques during the pulling process, teams can ensure a successful outcome. With careful planning and execution, wire pulling can be a smooth and trouble-free task, contributing to the overall success of any project.

Latest news

The Unique Design of Cable Socks

NewsJun.04,2025

Swivel Connectors in Industrial Automation

NewsJun.04,2025

Safety Features of Link Sticks

NewsJun.04,2025

How to choose the best cable pulling winch for sale

NewsJun.04,2025

Fish tape safety precautions

NewsJun.04,2025

Essential Maintenance Tips for Cable Pulling Tools

NewsJun.04,2025