-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

11월 . 22, 2024 09:00 Back to list

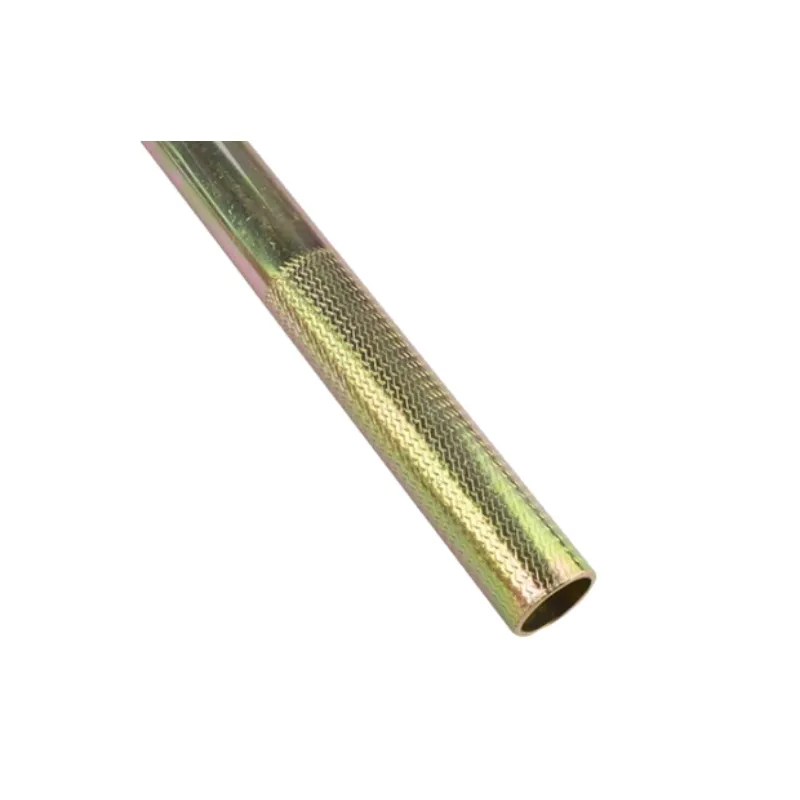

hydraulic cable punch machine

The Hydraulic Cable Punch Machine Revolutionizing Cable Processing

In modern manufacturing and construction, efficient tools are essential for optimizing productivity and ensuring high-quality output. One such tool that has significantly transformed cable processing is the hydraulic cable punch machine. This innovative equipment leverages hydraulic power to perform precise punching and cutting operations on various types of cables, making it an invaluable asset in industries ranging from electrical engineering to telecommunications.

The Mechanism of Hydraulic Punch Machines

Hydraulic punch machines operate on the principle of hydraulic force, which utilizes incompressible fluid to transmit power. The primary components of these machines include a hydraulic pump, a punch mechanism, and a control system. When the operator activates the machine, hydraulic fluid is directed to the punch mechanism, generating immense pressure that translates into force capable of cutting through hard materials.

The versatility of hydraulic punch machines is evident in their ability to handle a wide range of cable sizes and types, including copper and aluminum cables. This flexibility allows manufacturers to produce various products with differing specifications without the need for multiple machines, thereby streamlining the production process.

Key Features and Benefits

1. High Precision One of the standout features of hydraulic cable punch machines is their ability to perform highly accurate cuts and punches. The use of hydraulic systems minimizes human error and ensures that each cut is consistent, which is crucial when dealing with electrical components that require precise measurements.

2. Increased Efficiency Hydraulic machines are designed for high-speed operations, which significantly increases throughput. Manufacturers can punch and cut multiple cables in a short time frame, thereby enhancing overall productivity. This efficiency is particularly beneficial for large-scale projects where time is of the essence.

3. Ease of Use Modern hydraulic punch machines often come equipped with user-friendly control panels and features that allow for easy operation. With minimal training, operators can quickly learn how to adjust settings and manage the machine, reducing downtime associated with learning curves.

4. Safety Features Safety is a primary concern in industrial settings, and hydraulic cable punch machines are built with several safety features to protect operators. Emergency stop buttons, safety guards, and automatic shut-off mechanisms minimize the risk of accidents and injuries.

hydraulic cable punch machine

5. Durability and Reliability Built from robust materials, hydraulic punch machines are designed to withstand the rigors of heavy-duty use. This durability translates into lower maintenance costs and longer machine lifespan, making them a cost-effective investment for businesses.

Applications in Various Industries

The applications of hydraulic cable punch machines are vast and varied. In the electrical industry, they are used for manufacturing wiring harnesses, connectors, and various electronic components. The telecommunications sector also benefits from these machines to create high-quality cables and connectors that meet stringent industry standards.

Moreover, hydraulic punch machines are instrumental in automotive manufacturing, where they help produce wiring systems essential for vehicle functionality. The versatility of these machines enables them to adapt to different materials and specifications, which is crucial in industries that demand rapid innovation.

Future Trends

As technology evolves, so too do hydraulic cable punch machines. The integration of automation and smart technology is paving the way for more advanced machines that can operate with minimal human intervention. Features such as programmable logic controllers (PLCs) and real-time monitoring systems are expected to become standard in new models, enhancing efficiency and data management.

Furthermore, a growing emphasis on sustainability is driving manufacturers to design hydraulic machines that consume less energy and produce less waste. Innovators are exploring eco-friendly hydraulic fluids and energy-efficient systems to align with environmentally conscious practices.

Conclusion

The hydraulic cable punch machine stands as a testament to innovation in manufacturing technology. With their high precision, efficiency, and versatility, these machines have become crucial in various industries, facilitating the production of quality components while ensuring safety and durability. As we look towards the future, the continued evolution of these machines promises to enhance productivity further and pave the way for sustainable manufacturing practices. In a world increasingly reliant on complex electrical systems, the role of hydraulic punch machines will undoubtedly remain central to the advancement of industry standards and practices.

Latest news

What Are Construction Tools and How Are They Used?

NewsJul.11,2025

Professional-Grade Duct Rodding Tools for Superior Cable Installation

NewsJul.11,2025

Enhancing Safety and Efficiency with Modern Hot Stick Solutions

NewsJul.11,2025

Empowering Cable Installation with Advanced Rodder Solutions

NewsJul.11,2025

Elevate Your Cable Installation Projects with Cable Pulling Tools

NewsJul.11,2025

Efficient Cable Handling Solutions: Cable Rollers for Sale

NewsJul.11,2025