-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

ಡಿಸೆ . 10, 2024 10:42 Back to list

hydraulic pipe swaging machine

Hydraulic Pipe Swaging Machines Essential Tools for Precision Engineering

In the world of manufacturing and construction, the ability to join pipes and tubes efficiently and accurately is vital. Hydraulic pipe swaging machines have emerged as essential tools designed to meet these demands, providing manufacturers and fabricators with the means to create high-quality connections across various applications.

Understanding Hydraulic Pipe Swaging

Swaging is a process used to reduce the diameter of a pipe or to join two pieces of pipe together. This is accomplished by using a hydraulic swaging machine, which employs hydraulic pressure to deform the pipe material. The process can be used on a variety of materials, including steel, aluminum, copper, and plastic, making it versatile for different industries.

The hydraulic pipe swaging machine operates by placing the pipe in a die that molds it into the desired shape. The hydraulic system then exerts pressure on the pipes, which forces them into the die, resulting in seamless connections without the need for welding or other joining methods. This technique not only ensures strong and reliable joints but also reduces the need for additional fittings, leading to cost savings and efficiency in production.

Benefits of Hydraulic Pipe Swaging Machines

1. Precision and Consistency One of the most significant advantages of hydraulic swaging machines is their ability to produce consistent and precise fittings. The hydraulic pressure can be controlled with remarkable accuracy, ensuring that every pipe joint meets the desired specifications. This is particularly important in industries where tolerances are critical, such as aerospace and automotive manufacturing.

2. Speed Hydraulic swaging machines can significantly reduce the time required to join pipes. The quick operation of these machines allows for increased productivity on the shop floor. With faster processing times, manufacturers can meet tight deadlines without compromising quality.

hydraulic pipe swaging machine

3. Cost-Effectiveness By eliminating the need for additional fittings and reducing the time spent on assembly, hydraulic swaging machines can lead to significant cost savings. Additionally, the durability of swaged joints results in lower maintenance costs over time, as they are less likely to fail compared to other joining methods.

4. Versatility Hydraulic pipe swaging machines are capable of working with a wide range of materials and sizes. This versatility means that a single machine can be used for multiple applications, making it an invaluable asset for manufacturers with diverse project requirements.

5. Ease of Use Modern hydraulic swaging machines are designed with user-friendly interfaces and automated features. This means that operators can quickly learn to use the machines, reducing training time and allowing for smoother workflow integration.

Applications of Hydraulic Pipe Swaging Machines

The applications of hydraulic pipe swaging machines are vast. In the automotive sector, these machines are used to create fuel lines, brake lines, and exhaust components. In construction, they are employed for plumbing and HVAC systems, providing reliable connections that withstand high pressures. Additionally, industries such as oil and gas utilize swaging machines for pipe connections in harsh environments, where durability is paramount.

The medical field also benefits from hydraulic swaging technology, where precision is essential for equipment like respiratory devices and surgical tools. In fact, any industry that relies on fluid or gas transport can find value in the capabilities of hydraulic pipe swaging machines.

Conclusion

Hydraulic pipe swaging machines represent a pivotal advancement in pipe fabrication technology. With their ability to deliver precise, quick, and cost-effective solutions for joining pipes, these machines have become indispensable in various industries. As technological advancements continue to shape manufacturing processes, the reliance on hydraulic swaging machines is likely to grow, further enhancing the efficiency and effectiveness of pipe connections in both existing and emerging applications. For manufacturers looking to enhance their production capabilities, investing in a hydraulic pipe swaging machine can be a game-changing decision that pays dividends in quality and productivity.

Latest news

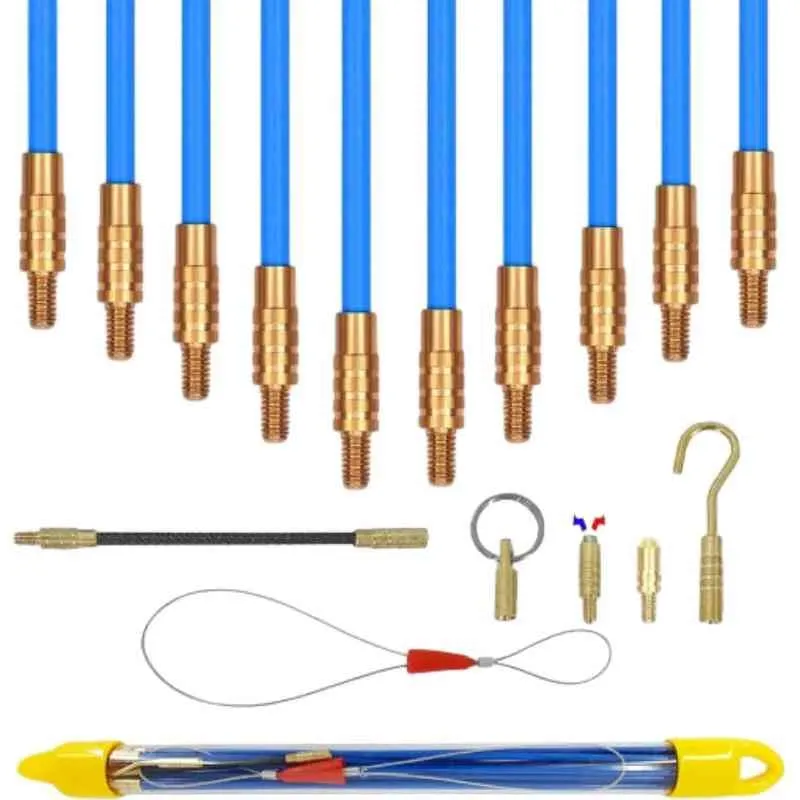

duct-rodders-and-conduit-rod-tools

NewsAug.22,2025

ratchet-pullers-and-wire-tightening-tools

NewsAug.22,2025

chain-ratchet-pullers-and-hoist-solutions

NewsAug.22,2025

telescopic-hot-stick-for-electrical-and-high-voltage-use

NewsAug.22,2025

cable-clamp-and-insulated-cable-clamp-systems

NewsAug.22,2025

duct-rodder-conduit-rodder-and-cable-solutions

NewsAug.22,2025