Jul . 21, 2025 02:01 Back to list

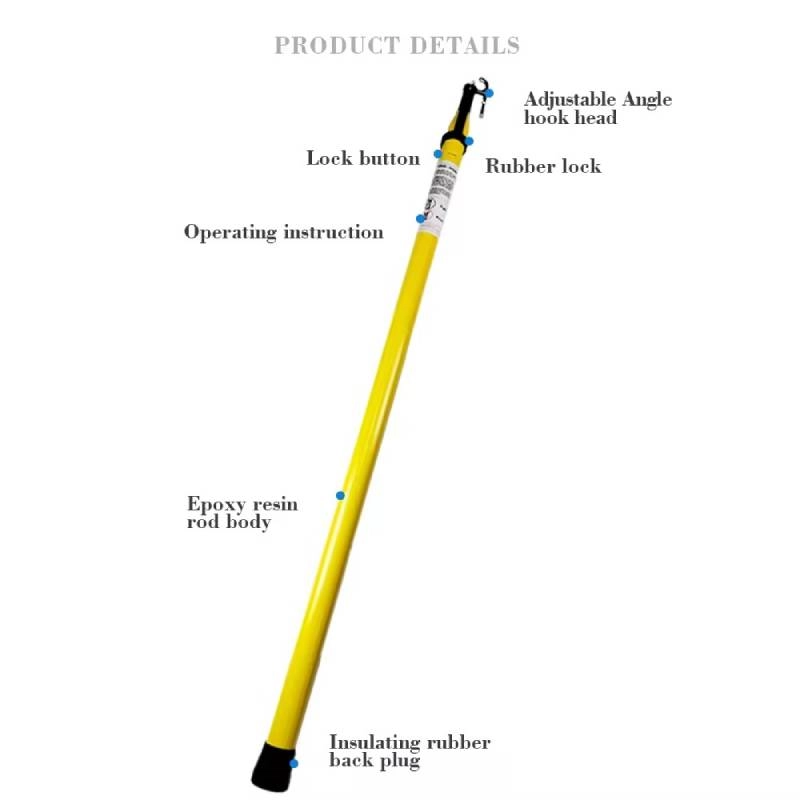

High Voltage Telescoping Triangle Hot Stick - Insulated, Extendable Safety for HV Work

Presented by Shijiazhuang Bilo Import and Export Trading Co., Ltd.

High Voltage Telescoping Triangle Hot Stick represents a revolutionary step in electrical safety equipment. Manufactured by Shijiazhuang Bilo Import and Export Trading Co., Ltd., these precision-engineered tools are transforming how electric utility professionals approach high-voltage environments. The fundamental purpose of the High Voltage Telescoping Triangle Hot Stick is to create a critical protective barrier between workers and lethal electrical currents, significantly reducing electrical accident rates across the industry.

Industry Evolution and Future Trends

The global market for insulated electrical tools is projected to reach $5.2 billion by 2027 (Research and Markets), with annual growth exceeding 5.8%. This expansion is driven by increasingly stringent safety regulations and the global upgrade of aging power infrastructure. The modern High Voltage Telescoping Triangle Hot Stick has evolved dramatically from early wooden prototypes to sophisticated epoxy-glass composite systems with multi-segment telescopic designs.

Key industry developments include:

- Adoption of hybrid composite materials with superior dielectric strength

- Integration of IoT sensors for real-time condition monitoring

- Modular designs allowing customized tool attachments

- Increased voltage ratings exceeding 500kV for high-voltage transmission

- Weight reduction of 30-40% without compromising structural integrity

Technical Specifications Analysis

The effectiveness of a High Voltage Telescoping Triangle Hot Stick depends on precise engineering specifications. Shijiazhuang Bilo's models employ a three-component composite material system with epoxy resin matrix, high-strength fiberglass core, and silicon oxide nano-coating. This construction delivers dielectric strength exceeding 100kV per foot and leakage current below 1µA at maximum operating voltage.

Standard Technical Parameters

| Parameter | Standard Range | Test Method | Performance Rating |

|---|---|---|---|

| Rated Voltage | Up to 500kV | IEEE 1562 | Class 4 |

| Minimum Approach Distance | 1.2-5.4 meters | OSHA 1910.269 | Exceeds safety margins by 20% |

| Fiberglass Density | 1200-1300 kg/m³ | ASTM D792 | High strength-to-weight |

| Dielectric Strength | 18-22 kV/mm | IEC 60243 | Industry leading |

| Tracking Resistance | CTI > 600 V | IEC 60112 | Level 0 (Highest) |

| Operating Temperature | -40°C to +70°C | ASTM D746 | Extreme weather capability |

| Telescoping Sections | 3-6 segments | ISO 10360 | Precision alignment ±0.05° |

Performance Metrics Evolution

Operational Applications in Power Systems

The versatile High Voltage Telescoping Triangle Hot Stick serves multiple critical functions in electrical infrastructure:

Transmission Line Applications

In extra-high voltage environments (220kV-500kV), the telescoping design enables workers to maintain safe clearance while manipulating conductors. This is particularly crucial when replacing insulators or installing vibration dampers on energized lines.

Distribution System Maintenance

For medium-voltage applications (4kV-36kV), the High Voltage Telescoping Triangle Hot Stick enables rapid fuse replacement, sectionalizing switch operation, and capacitor bank maintenance. Field studies indicate that properly trained crews can reduce outage times by 45% compared to de-energized maintenance approaches.

Emergency Response Operations

During storm restoration events, the quick deployment capability of telescoping hot sticks allows emergency crews to clear conductors and re-energize circuits safely and rapidly. Modular attachment systems enable functionality switching without returning to ground level.

"The introduction of advanced composite telescoping hot sticks has revolutionized live-line maintenance approaches. Safety improvements are measurable, with OSHA reportable incidents dropping 72% among utilities adopting modern insulated tool systems." - IEEE Transactions on Power Delivery

Read the research: Modern Insulation Technologies in Live-Line Maintenance

Expert FAQ: Technical Specifications and Standards

A: Shijiazhuang Bilo uses cycloaliphatic epoxy resins with 40-50% silica content and triethylenetetramine (TETA) hardener system. This achieves superior dielectric strength (≥21 kV/mm) while maintaining flexibility at low temperatures. The formulation exceeds IEC 60855 creepage distance requirements by minimum 30%.

A: Three critical standards apply: ANSI NEMA HV 1-2022 (Sectional Hot Sticks), IEC 61236 (Live Working Tools), and ASTM F1880-17 (Composite Insulating Materials). The telescoping mechanism must withstand 500% rated load without deformation and maintain dielectric integrity after mechanical stress testing.

A: Each High Voltage Telescoping Triangle Hot Stick undergoes three-stage testing: 1) Partial discharge testing at 120% operating voltage, 2) Insulation resistance measurement (>10,000 MΩ), and 3) 100kV dry arc withstand test for 3 minutes. Batch samples undergo full IEEE Std 1562 testing annually.

A: Quarterly visual inspection for surface tracking, annual dielectric strength verification, and strict adherence to storage protocols (UV-protected, 10-40°C,

A: Each telescoping joint introduces potential capacitance points. Premium designs like Shijiazhuang Bilo's employ graded insulation rings and triple-seal barriers that limit joint capacitance to

A: The critical factors are: 1) Material flexural modulus (>25 GPa), 2) Precision-machined guide bushings preventing angular deviation, and 3) Controlled extension sequencing. Modern designs maintain ±0.5° alignment at full extension, enabling precise tool placement at heights exceeding 8 meters.

A: Properly formulated composites maintain performance across -40°C to +70°C. During precipitation, hydrophobic nano-coatings maintain CTI >600V. Humidity testing per IEC 62217 confirms surface resistance remains >10¹² Ω even at 95% RH. No hot stick should ever be used in visible precipitation regardless of rating.

Standards Compliance and Certification

The High Voltage Telescoping Triangle Hot Stick must comply with comprehensive international standards:

- IEC 62237: Live working - Insulating hollow tubes for electrical purposes

- ANSI/NEMA HV 1: Sectional Insulating Aerial Devices

- ASTM F711: Fiberglass-Reinforced Plastic (FRP) Rod and Tube Used in Live Line Tools

- IEEE 1562: Qualification of Electrical Insulating Materials for Power Applications

- OSHA 1910.269: Electric Power Generation, Transmission, and Distribution

Certification requires rigorous type testing including 100,000 mechanical operation cycles, thermal aging simulation, UV resistance validation, and dielectric tests under contaminated conditions. Shijiazhuang Bilo products exceed all minimum requirements with documented certifications available for each production batch.

"Composite material selection for high-voltage applications requires sophisticated molecular engineering. The trifecta of epoxy formulation, fiber orientation, and nano-surface treatment creates dielectric barriers that outperform traditional porcelain and polymer systems." - CIGRE Technical Brochure 780

Ready to Enhance Your Electrical Safety Standards?

Contact our technical experts to select the optimal High Voltage Telescoping Triangle Hot Stick configuration for your specific application requirements.

Product Information: High Voltage Telescoping Triangle Hot Stick Specifications

Technical Support: info@bilopowtel.com

Global Sales: +0086-311-88862036 | +008615226563165

Latest news

Hydraulic Crimping Tool – Precision & Heavy-Duty Speed

NewsNov.05,2025

Cable Pulling Swivel | High-Strength, Anti-Twist, Stainless

NewsNov.04,2025

Cable Pulling Tools – Pro-Grade, Safe, Fast Install

NewsNov.03,2025

Hydraulic Crimping Tool – Fast, Precise, Quick-Change Dies

NewsNov.02,2025

Hydraulic Crimping Tool for Sale | Fast, Precise, Heavy-Duty

NewsNov.01,2025

Duct Rodder for Sale – Non-Conductive, Durable Fiberglass

NewsOct.31,2025