-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

12月 . 27, 2024 16:08 Back to list

hot stick electrical safety

Understanding Hot Stick Electrical Safety

In the world of electrical maintenance and utility work, safety is of paramount importance. One of the essential tools employed by electricians and lineworkers is the hot stick, also known as an insulated pole or telecommunication pole. This specialized equipment is designed to ensure that workers can safely work on or near live electrical lines without risking electric shock or injury. This article delves into the significance of hot stick electrical safety and best practices to mitigate risks.

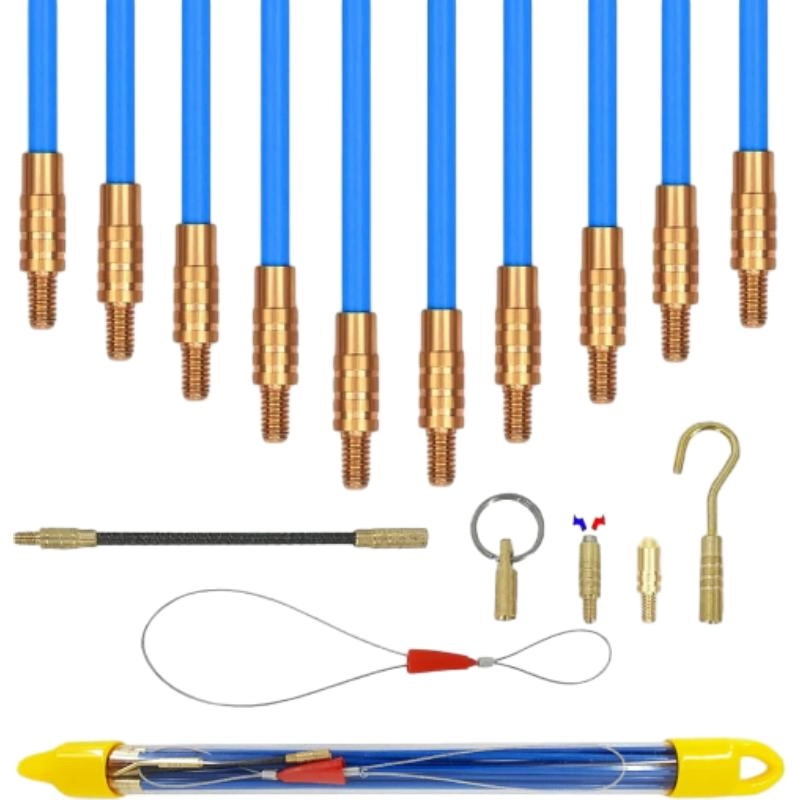

What is a Hot Stick?

A hot stick is an elongated, insulated rod made from non-conductive materials such as fiberglass or composite materials. Its principal purpose is to allow workers to safely manipulate electrical components without direct contact. Hot sticks come in various lengths and are equipped with different attachments depending on the task—be it switching, fusing, or testing.

The insulation properties of a hot stick are crucial; they prevent electricity from passing through the device and reaching the worker. This technology facilitates maintenance, emergency repairs, and various routine tasks while minimizing the risk associated with high-voltage environments.

Importance of Hot Stick Safety

The importance of hot stick safety cannot be overstated. Electrical workers are exposed to potentially life-threatening situations daily, with electric shock being one of the leading causes of injury and fatality in this field. Using a hot stick correctly dramatically reduces this risk.

Moreover, electric utilities must comply with strict safety regulations and standards mandated by organizations such as the Occupational Safety and Health Administration (OSHA) and the National Electric Code (NEC). These regulations outline the minimum safety requirements, emphasizing the necessity of using insulated tools like hot sticks when performing line work energized above a certain voltage level.

Best Practices for Using Hot Sticks

hot stick electrical safety

1. Regular Inspections Before each use, hot sticks should be meticulously inspected for any signs of damage, wear, or defects. Workers should check for cracks, chips, or other impairments that could compromise the stick’s insulation. Any damaged hot stick should be taken out of service immediately for repairs or replacement.

2. Training and Certification Proper training is essential for all personnel who utilize hot sticks. Workers should be familiar with the correct techniques for using the tools, including how to handle them safely, the appropriate distances to maintain from energized components, and how to react in an emergency. Certification programs that focus on safety standards contribute to increased awareness and preparedness.

3. Proper Handling Techniques When using a hot stick, workers should maintain a firm grip and use two hands when necessary to ensure stability and control. Keeping a safe distance from the electrical source is vital, and users should avoid leaning on or resting against energized equipment while manipulating a hot stick.

4. Environmental Awareness Electricians should be acutely aware of their surroundings and environmental factors that could affect safety. Weather conditions, such as rain or high winds, can significantly alter the risk associated with electric work. Outdoor work requires extra caution and planning to ensure that conditions are suitable for safe operations.

5. Emergency Procedures Workers must understand the emergency procedures if something goes awry. Training should emphasize evacuating the area, using equipment to de-energize lines, and coordinating with emergency crews. Familiarity with these procedures can make a critical difference in a high-stress situation.

6. Personal Protective Equipment (PPE) Although hot sticks provide a significant safety barrier, they are not a substitute for proper PPE. Electricians should wear insulated gloves, safety helmets, and fire-resistant clothing to further reduce the risk of injury.

Conclusion

Hot stick electrical safety is a crucial element of workplace safety in the electrical field. Employing best practices, understanding the importance of regular inspections, training, handling techniques, environmental awareness, emergency procedures, and PPE usage are fundamental in ensuring that workers remain safe while performing potentially dangerous tasks. By prioritizing hot stick safety, we not only protect our workforce but also enhance the overall reliability and efficiency of our electrical systems.

Latest news

What Are Construction Tools and How Are They Used?

NewsJul.11,2025

Professional-Grade Duct Rodding Tools for Superior Cable Installation

NewsJul.11,2025

Enhancing Safety and Efficiency with Modern Hot Stick Solutions

NewsJul.11,2025

Empowering Cable Installation with Advanced Rodder Solutions

NewsJul.11,2025

Elevate Your Cable Installation Projects with Cable Pulling Tools

NewsJul.11,2025

Efficient Cable Handling Solutions: Cable Rollers for Sale

NewsJul.11,2025