Oct . 10, 2025 09:30 Back to list

Hot Stick: Lighter, Safer, Longer Reach—Why Upgrade Now?

High Voltage Telescoping Triangle hot stick: field notes from the line

If you spend any time around distribution crews, you know the simple truth: the right tool keeps the lights on and people safe. This triangle-profile, telescoping hot stick from China’s Bilopowtel has been popping up in utility depots I visit. At first I was skeptical (I usually am), but the details—materials, test data, and the non-rotating tube—won me over. It’s built for long reach, quick deployment, and, frankly, fewer heart-in-throat moments aloft.

Why the triangle matters (and other trends)

Utilities are trimming outage minutes and working more “hot” on renewables-tied feeders. The triangle profile doesn’t spin under torque—so switching blades, fuse barrels, and tie wires go on straight, first try. Telescoping sections mean fewer truck rolls for the “wrong length” tool. And, yes, crews keep asking for lighter sticks with better UV topcoats; manufacturers are finally catching up.

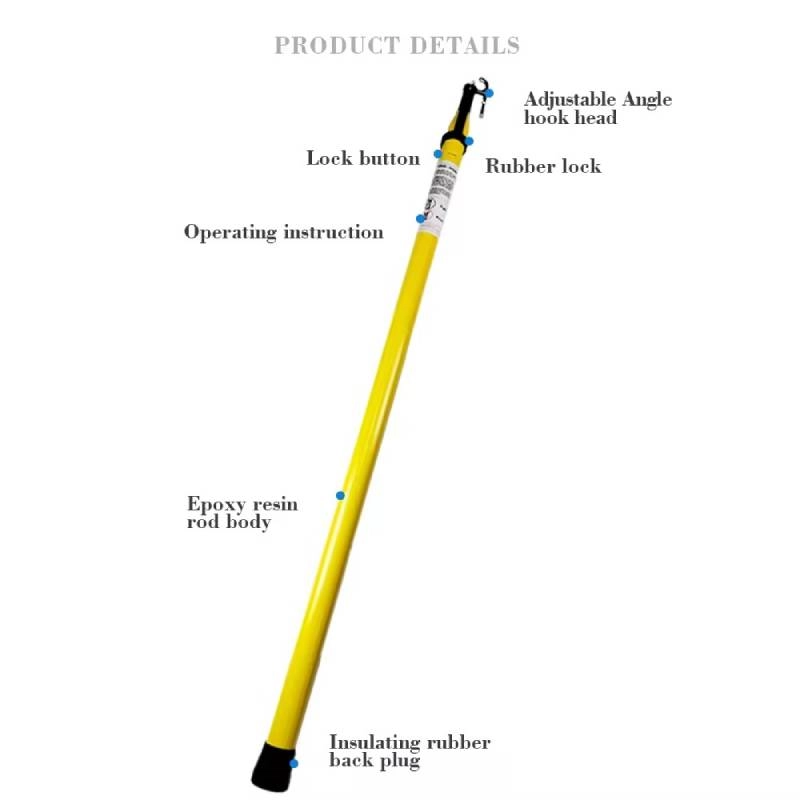

Core specs at a glance

| Material | Epoxy resin + high-quality fiberglass (pultruded tubes), UV-resistant gelcoat |

| Dielectric withstand (type test) | ≈ 100 kV/30 cm dry; ≈ 75 kV/30 cm wet, leakage current |

| Length (collapsed / extended) | Around 1.7 m / 6–9 m options; multi-section telescoping |

| Locking | Positive button locks; triangle profile prevents rotation |

| Heads & fittings | Universal head compatible with hooks, cutters, fuse pullers, voltage indicators, tie tools |

| Service life | 10–15 years with care per ASTM F496, annual dielectric checks |

How it’s built and tested

Materials: pultruded fiberglass reinforced plastic with an epoxy matrix for rigidity and dielectric strength; exterior UV topcoat; hydrophobic surface finish for wet performance.

Methods: precision pultrusion, triangle die forming, section tuning for stiffness-to-weight, tip bonding and universal head fitting, then bake-cure and polish. To be honest, the finish on newer batches looks cleaner than last year’s run.

Testing: dielectric per ASTM F711 (type), in-service care ASTM F496, and conformity to IEC 61235 / IEC 60855-1 for live working tubes and rods. Field checks: wet-wipe, wax, and a quick leakage test before a storm call—old habits, still good ones.

Where crews use this hot stick

- Open/close disconnects and reclosers fast, from a safer distance.

- Replace cutouts/fuses; tighten hardware; apply tie wires and insulating sleeves.

- Wind O&M, substations, and electrified rail maintenance where access is awkward.

- Voltage presence testing with clip-on indicators before hands go near anything.

Customization options

Lengths (3–9 m), section counts, orange or safety-yellow coats, laser-etched inch/cm markings, private labeling, and kits with hooks, fuse pullers, and voltage detectors. Many customers say the triangle profile plus contrast markings reduce “misreach” at dawn or in rain.

Vendor comparison (quick take)

| Criteria | Bilopowtel (Origin: China) | Vendor A (US) | Vendor B (EU) |

|---|---|---|---|

| Profile / Lock | Triangle, button locks | Round/Triangle, button | Round, cam |

| Dielectric rating | ≈100 kV/30 cm dry | ≈100–125 kV/30 cm dry | ≈90–110 kV/30 cm dry |

| Weight (6 m) | Around 3.8–4.6 kg | Around 4.0–5.0 kg | Around 4.2–5.2 kg |

| Lead time | 2–5 weeks typical | 2–6 weeks | 3–7 weeks |

Field notes, cases, and compliance

Case 1: A South China distribution utility swapped aging round sticks for the triangle model; switching errors dropped noticeably and SAIDI nudged down after a wet season. Case 2: A coastal wind farm reported better wet-grip and fewer slips on nacelle work, which is not nothing on a windy Tuesday.

Typical test data from factory reports: dry withstand >100 kV/30 cm; wet withstand ≈75 kV/30 cm; torque at head >45 N·m without rotation. Certifications: ISO 9001 for quality systems; design and testing aligned with OSHA 1910.269 work practices, IEEE 516 guidance, ASTM F711/F496, and IEC 61235/60855-1.

Bottom line: this hot stick feels purpose-built for modern crews—fast to deploy, steady under torque, and backed by the test standards that matter. And, actually, that triangle? You notice it most when you don’t notice it at all.

References

- OSHA 1910.269 Electric Power Generation, Transmission, and Distribution

- ASTM F711: FRP Rod and Tube Used in Live Line Tools

- ASTM F496: In-Service Care of Live-Line Tools

- IEC 61235: Live working — Insulating hollow tubes

- IEC 60855-1: Live working — Insulating foam-filled tubes and rods

- IEEE 516: Guide for Maintenance Methods on Energized Power Lines

Latest news

Hydraulic Crimping Tool – Precision & Heavy-Duty Speed

NewsNov.05,2025

Cable Pulling Swivel | High-Strength, Anti-Twist, Stainless

NewsNov.04,2025

Cable Pulling Tools – Pro-Grade, Safe, Fast Install

NewsNov.03,2025

Hydraulic Crimping Tool – Fast, Precise, Quick-Change Dies

NewsNov.02,2025

Hydraulic Crimping Tool for Sale | Fast, Precise, Heavy-Duty

NewsNov.01,2025

Duct Rodder for Sale – Non-Conductive, Durable Fiberglass

NewsOct.31,2025