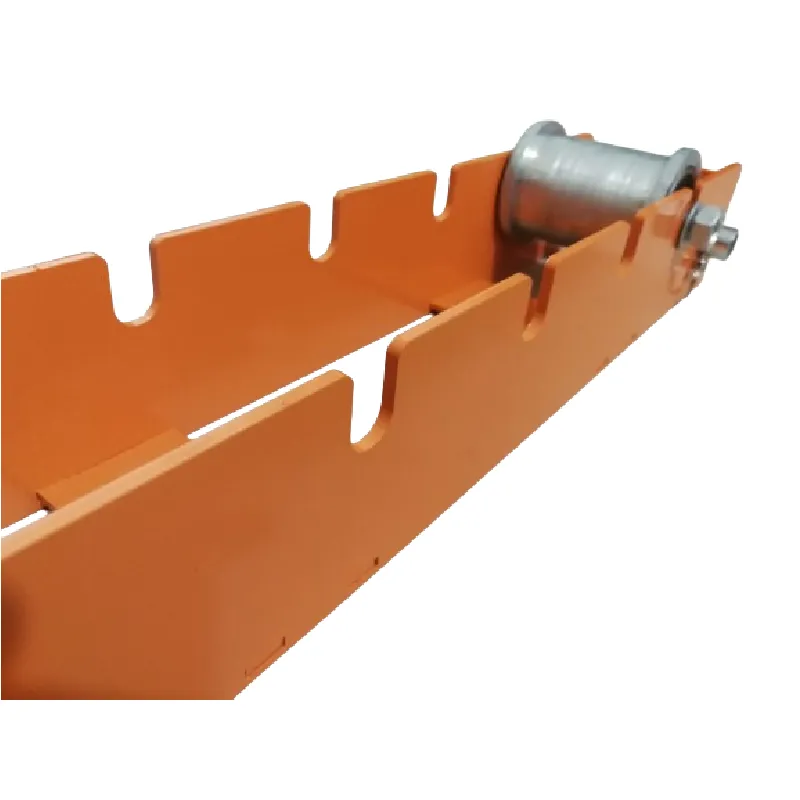

- 1. Nws cov qauv tsim tshwj xeeb ua kom cov kab sib txuas du thiab txo qis hnav thiab tsim kua muag.

- 2. Cov menyuam ua haujlwm du nrog lub luag haujlwm hnyav steel pob bearings muab ib qho yooj yim cable tawm yam tsis muaj kev tawg lossis khoov.

- 3. Cov pob bearings no kuj yog "Lub neej kaw," tiv thaiv dej los yog plua plav nkag rau ntawm qhov chaw tsim kho lossis hauv qhov chaw rugged.

- 4. Cov bearings yog encapsulated los ntawm check zinc-coated steel cylinders. Hnyav-duty cable reels tuaj yeem hloov tau yooj yim thiab yooj yim los ntawm nias lub caij nplooj ntoos hlav-loaded nruab nrab qag ncej thiab tshem tawm lub tog raj kheej los ntawm cov hlau ncej.

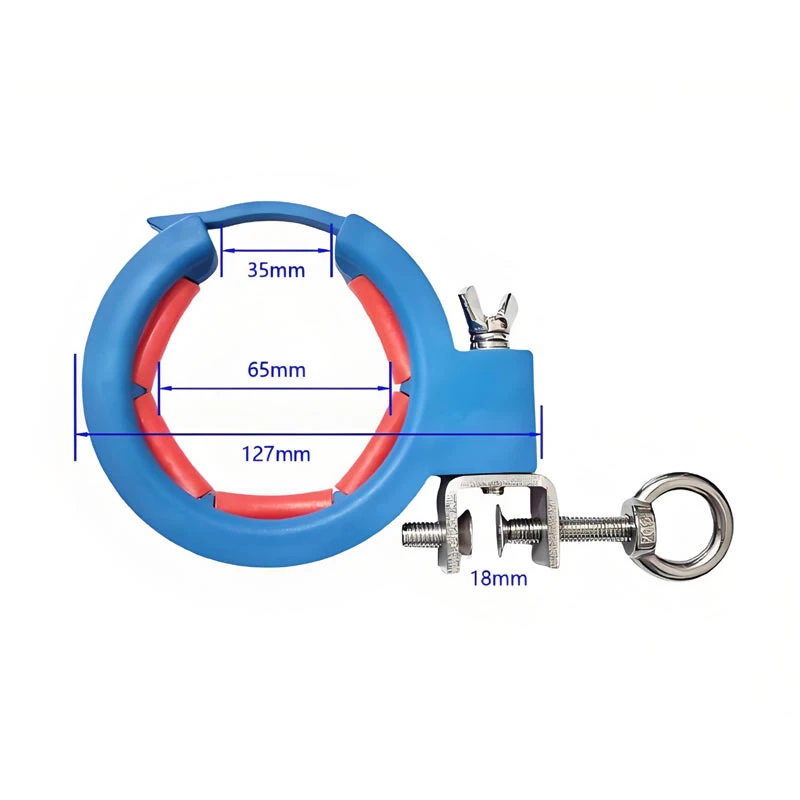

|

Suitable cable drum Dia |

400mm-1200mm |

|

Suitable cable drum Max width |

8 26mm |

|

Max loading capacity |

2000 kgs |

|

N.W |

25 kgs |

|

G.W |

26 kqb |

|

Loj |

100 * 90 * 11.2cm |

|

Package Size |

101 * 31 * 13.5cm |

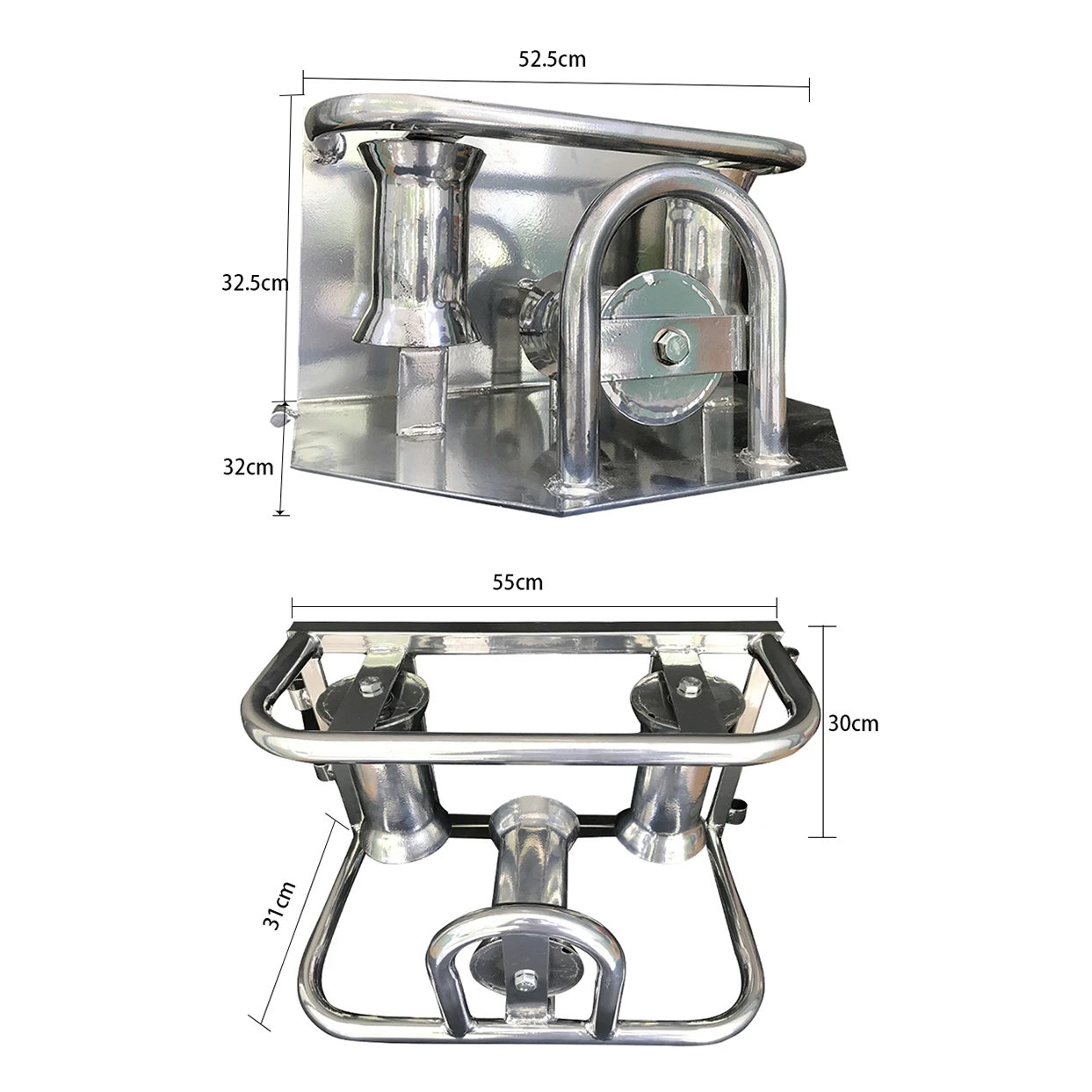

- 1. Ob lub platforms yuav tsum tau muab tso rau zoo nyob rau hauv lub hauv paus ntawm lub reel dav.

- 2. Cov menyuam nyob ze ntawm txoj kab nqes yuav tsum tau muab xauv.

- 3. Txoj hauj lwm ntawm cov menyuam yuav tsum tau kho raws li txoj kab uas hla reel.

- 4. Lub reel yuav tsum raug thawb mus rau lub platform raws txoj kab nqes.

- 5. Relieve lub xauv cov menyuam, thiab tom qab ntawd lub reel tuaj yeem tig.

Cable nruas rollers thiab dispensers yog qhov zoo tshaj plaws ntxiv rau txhua qhov chaw teeb tsa hluav taws xob, tso cai rau cov cables kom tau yooj yim tsis muaj pob los yog tangling. Lawv muaj nyob rau hauv ntau qhov ntau thiab tsawg los ua kom haum rau ntau qhov me me cable nruas, nrog cov hauv paus ruaj khov thiab cov chais los pab kev xa tawm thiab rov qab cable. Lawv yog siv nyob rau hauv ntau yam ntawm ib puag ncig.

How to Choose the Right Cable Drum Roller Jack for Your Project

Selecting the correct cable drum roller jack is critical for ensuring efficient, safe, and reliable cable installation. These devices are designed to support and rotate heavy cable drums, allowing cables to be pulled smoothly without twisting, tangling, or damaging the cable. Choosing the right roller jack involves understanding your project requirements, including drum size, load capacity, material, and operational environment.

1. Understand the Function of a Cable Drum Roller Jack

A cable drum roller jack serves as a support and rotation platform for cable drums. By lifting the drum off the ground and enabling controlled rotation, it reduces friction and prevents excessive strain on the cable during installation. This is especially important for long runs, heavy-duty industrial cables, or fiber optic lines, where even minor twisting or kinking can cause performance issues or damage.

The roller jack ensures smooth cable payout, improves installation speed, and minimizes physical effort for operators. Many models also feature adjustable heights or pivoting rollers, which help accommodate different drum sizes and uneven surfaces.

2. Determine Drum Size and Weight Capacity

The first step in selecting a cable drum roller jack is to evaluate the size and weight of the cable drums you will be using. Roller jacks come in various load capacities, from small, portable models suitable for lighter control cables to heavy-duty jacks designed for large power cables weighing several tons.

Ensure that the roller jack you choose can safely support the full weight of the drum, including any additional tension that may occur during rotation. Choosing a jack with an adequate weight margin not only ensures safety but also prolongs the lifespan of the equipment.

3. Consider Material and Durability

Cable drum roller jacks are typically made from steel, stainless steel, or heavy-duty aluminum. Steel models offer high strength and are suitable for heavy industrial or utility applications. Stainless steel provides excellent corrosion resistance, making it ideal for outdoor or marine environments. Aluminum jacks are lighter and more portable, suitable for temporary setups or lighter cables.

Additionally, consider the quality of the roller bearings and frame construction. Durable bearings ensure smooth drum rotation under heavy loads, while a robust frame prevents deformation or instability during operation.

4. Evaluate Operational Features

Modern cable drum roller jacks often include features that enhance safety and ease of use. Adjustable roller positions, pivoting rollers, and locking mechanisms help accommodate various drum sizes and ensure controlled cable payout. Some jacks also include integrated wheels or handles for easier transport between job sites.

Safety features, such as non-slip rollers and secure drum locking, reduce the risk of accidents and protect both the cable and operators. Consider these features based on your project’s environment, whether it’s an indoor facility, construction site, or outdoor terrain.

5. Match the Jack to Your Project Needs

Ultimately, the right cable drum roller jack depends on your project’s specific requirements. Assess the typical drum sizes, cable types, load capacity, and environmental conditions before making a selection. Investing in a high-quality, durable roller jack ensures smoother installations, reduces cable damage, and enhances workplace safety.

Conclusion

Choosing the right cable drum roller jack requires careful consideration of drum size, weight capacity, material, and operational features. By selecting a model suited to your project, you can improve efficiency, reduce physical strain on operators, and protect your cables from damage. A well-chosen roller jack is an essential tool for any professional cable installation project, ensuring reliability, safety, and long-term performance.

Enhancing Safety and Efficiency with Cable Drum Roller Jacks

In modern cable installation projects, safety and efficiency are critical priorities. Handling heavy cable drums improperly can lead to injuries, equipment damage, and costly downtime. Cable drum roller jacks are specialized tools designed to support, lift, and rotate cable drums safely, making them indispensable for industrial, utility, and construction applications. By using the right roller jack, operators can streamline cable installation while significantly reducing the risk of accidents.

1. Improving Safety During Cable Installation

A primary benefit of cable drum roller jacks is enhanced safety. Without proper support, heavy cable drums can be unstable, making manual handling hazardous. Roller jacks lift the drum off the ground, allowing it to rotate smoothly while preventing tipping or uncontrolled movement. This minimizes the risk of injuries from falling drums or strained muscles due to improper lifting techniques.

Many roller jacks also feature secure locking mechanisms, non-slip rollers, and robust frames that keep the drum in place during the pulling process. These safety features ensure that operators can work with confidence, even when handling large or heavy cables in challenging environments.

2. Enhancing Operational Efficiency

Efficiency is another key advantage of using cable drum roller jacks. By enabling smooth drum rotation, the roller jack reduces friction and stress on the cable during payout. This allows for faster cable deployment, whether pulling through conduits, trenches, or across open terrain.

Adjustable rollers and height settings accommodate various drum sizes, ensuring compatibility with different cable types and project requirements. The smooth operation of the drum also prevents cable twisting, tangling, or kinking, which can save significant time that would otherwise be spent correcting installation errors.

3. Reducing Equipment and Cable Damage

Improper cable handling can result in damaged cables, increased maintenance costs, or compromised system performance. Cable drum roller jacks distribute weight evenly and allow controlled rotation, reducing strain on both the cable and the drum. By minimizing direct contact with the ground or uneven surfaces, the jack prevents abrasion and deformation, preserving cable integrity throughout the installation process.

Additionally, high-quality jacks are constructed from durable materials such as steel or stainless steel, ensuring long-term reliability under heavy loads. Bearings and rollers are designed to withstand continuous use, further protecting both the equipment and the cables being installed.

4. Versatility Across Applications

Cable drum roller jacks are highly versatile tools suitable for various industries, including power distribution, telecommunications, industrial manufacturing, and construction. Portable models are available for temporary or remote sites, while heavy-duty jacks can handle large, high-capacity drums used in industrial or utility projects. This adaptability makes them essential for any project that involves cable handling, regardless of size or complexity.

Conclusion

Cable drum roller jacks play a crucial role in enhancing both safety and efficiency during cable installation. By providing secure support, smooth drum rotation, and protection for cables, these tools reduce the risk of injuries, minimize equipment damage, and streamline operations. Investing in the right roller jack ensures reliable, efficient, and safe cable installation for a wide range of industrial, utility, and construction applications.

The Function and Benefits of Cable Drum Roller Jacks in Cable Installation

Efficient and safe cable installation requires specialized tools that can handle heavy cable drums while protecting the cable and ensuring smooth deployment. Cable drum roller jacks are essential equipment in this process, providing support, controlled rotation, and ease of handling for both industrial and utility applications. Understanding their function and benefits can help project managers and technicians optimize installation efficiency and minimize risks.

1. Understanding the Function of Cable Drum Roller Jacks

A cable drum roller jack is designed to lift, support, and rotate cable drums during installation. By raising the drum off the ground, the jack reduces friction between the drum and the surface, allowing cables to be pulled smoothly without twisting, kinking, or stretching. This is particularly important for long runs or heavy-duty cables, where uncontrolled movement can result in damage or installation delays.

The roller jack’s design typically includes adjustable rollers, a stable frame, and, in some models, ratcheting mechanisms or locking features. These elements ensure that the drum remains securely in place while rotating, allowing operators to maintain consistent tension and control over the cable during installation.

2. Key Benefits of Using Cable Drum Roller Jacks

Cable drum roller jacks provide several important advantages that enhance both efficiency and safety:

Improved Safety: Handling heavy cable drums manually can lead to injuries, especially on uneven terrain or in confined spaces. Roller jacks stabilize the drum, reducing the risk of tipping, rolling, or accidental drops.

Enhanced Efficiency: Smooth drum rotation reduces friction, making cable deployment faster and requiring less manual effort. Adjustable features allow operators to accommodate various drum sizes quickly, improving workflow.

Protection for Cables: By keeping the drum elevated and ensuring even rotation, roller jacks minimize cable twisting, kinking, or abrasion. This preserves the integrity of the cable’s insulation and conductors, reducing maintenance and replacement costs.

Durable and Reliable: High-quality roller jacks are constructed from steel, stainless steel, or aluminum, ensuring long-term durability under heavy loads and harsh environments. Bearings and rollers are designed for continuous use, maintaining smooth operation throughout the project.

Versatility: Cable drum roller jacks can be used across a variety of applications, including electrical power distribution, telecommunications, industrial installations, and construction projects. Portable and heavy-duty models cater to different project scales and environments.

3. Applications in Cable Installation

These jacks are used in tasks ranging from installing overhead power lines to deploying underground cables in ducts or trenches. They are particularly beneficial for long-distance cable runs, large industrial projects, and environments where manual handling would be difficult or unsafe. By providing stability and controlled rotation, roller jacks ensure that cables are installed efficiently and with minimal risk of damage.

Conclusion

Cable drum roller jacks are indispensable tools for modern cable installation. By offering secure support, controlled rotation, and protection for cables, they enhance both safety and efficiency on the job site. Investing in the right roller jack not only streamlines installation but also reduces potential damage, labor costs, and downtime, making them a critical component for any professional cable installation project.