-

אַפְרִיקַנִי

אַפְרִיקַנִי -

אלבני

אלבני -

אמהרית

אמהרית -

עֲרָבִית

עֲרָבִית -

אַרְמֶנִי

אַרְמֶנִי -

אזרבייג'נית

אזרבייג'נית -

באסקית

באסקית -

בלארוסית

בלארוסית -

בנגלית

בנגלית -

בוסנית

בוסנית -

בולגרית

בולגרית -

קטלאנית

קטלאנית -

סבואנו

סבואנו -

קורסיקאי

קורסיקאי -

קרואטית

קרואטית -

צ'כית

צ'כית -

דַנִי

דַנִי -

הוֹלַנדִי

הוֹלַנדִי -

אנגלית

אנגלית -

אֶסְפֵּרַנְטוֹ

אֶסְפֵּרַנְטוֹ -

אסטונית

אסטונית -

פִינִית

פִינִית -

צָרְפָתִית

צָרְפָתִית -

פריזית

פריזית -

גליציאנית

גליציאנית -

גרוזינית

גרוזינית -

גֶרמָנִיָת

גֶרמָנִיָת -

יווני

יווני -

גוג'ראטי

גוג'ראטי -

קריאולי האיטי

קריאולי האיטי -

האוסה

האוסה -

הוואי

הוואי -

עִברִית

עִברִית -

לא

לא -

מיאו

מיאו -

הוּנגָרִי

הוּנגָרִי -

איסלנדית

איסלנדית -

איבו

איבו -

אינדונזית

אינדונזית -

אִירִית

אִירִית -

אִיטַלְקִית

אִיטַלְקִית -

יַפָּנִית

יַפָּנִית -

ג'אוואנית

ג'אוואנית -

קנאדה

קנאדה -

קזחית

קזחית -

חמר

חמר -

רואנדה

רואנדה -

קוריאנית

קוריאנית -

כּוּרדִי

כּוּרדִי -

קירגיזית

קירגיזית -

שַׁחֶפֶת

שַׁחֶפֶת -

לָטִינִית

לָטִינִית -

לטבית

לטבית -

ליטאית

ליטאית -

לוקסמבורג

לוקסמבורג -

מקדונית

מקדונית -

מלגאשי

מלגאשי -

מלאית

מלאית -

מלאיאלאם

מלאיאלאם -

מלטזית

מלטזית -

מאורי

מאורי -

מראטי

מראטי -

מוֹנגוֹלִי

מוֹנגוֹלִי -

מיאנמר

מיאנמר -

נפאלית

נפאלית -

נורבגית

נורבגית -

נורבגית

נורבגית -

אוקסיטנית

אוקסיטנית -

פשטו

פשטו -

פַּרסִית

פַּרסִית -

פולני

פולני -

פורטוגזית

פורטוגזית -

פנג'בי

פנג'בי -

רומנית

רומנית -

רוּסִי

רוּסִי -

סמואנית

סמואנית -

גאלית סקוטית

גאלית סקוטית -

סרבית

סרבית -

אנגלית

אנגלית -

שונה

שונה -

סינדהי

סינדהי -

סינהאלה

סינהאלה -

סלובקית

סלובקית -

סלובנית

סלובנית -

סומלית

סומלית -

ספרדית

ספרדית -

סונדני

סונדני -

סוואהילית

סוואהילית -

שוודית

שוודית -

טאגלוג

טאגלוג -

טג'יקית

טג'יקית -

טמילית

טמילית -

טטרית

טטרית -

טלוגו

טלוגו -

תאילנדית

תאילנדית -

טורקי

טורקי -

טורקמנית

טורקמנית -

אוקראינית

אוקראינית -

אורדו

אורדו -

אויגורי

אויגורי -

אוזבקית

אוזבקית -

וייטנאמית

וייטנאמית -

וולשית

וולשית -

עֶזרָה

עֶזרָה -

אִידִישׁ

אִידִישׁ -

יורובה

יורובה -

זולו

זולו

אוג . 13, 2025 10:21 בחזרה לרשימה

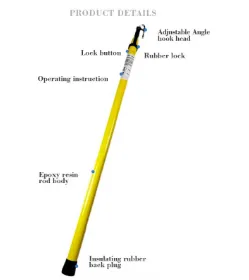

Reliable Protection with Advanced Hot Stick Technology

In the high-risk world of electrical power distribution, ensuring safety without compromising efficiency is paramount. Tools that allow technicians to perform complex operations while staying at a safe distance from high-voltage lines are essential. Among these, the hot stick electrical tool stands out as one of the most critical. Engineered to meet stringent industry standards, the telescopic hot stick, high voltage hot stick, and מקל חם טלסקופי models offer unmatched reach, durability, and reliability, making them indispensable for any utility crew working in energized environments.

Uncompromising Safety Standards in Electrical Environments

The core reason for the widespread adoption of hot stick electrical tools lies in their proven ability to protect linemen and utility technicians from life-threatening electrical hazards. These tools are crafted using high-quality, non-conductive materials such as epoxy resin and reinforced fiberglass. These materials ensure excellent insulation and mechanical strength, critical factors when working near high-voltage lines.

When technicians perform routine tasks like opening switches or replacing fuses, direct contact with energized components is never necessary. The telescopic hot stick allows workers to maintain a secure distance while executing complex operations. In high-voltage scenarios, the importance of this separation cannot be overstated. The tools are rigorously tested under extreme conditions to verify dielectric properties, ensuring every stick can be relied upon in the field. This attention to safety enables utility workers to function confidently and reduces the risk of workplace incidents.

Innovative Telescoping Design for Enhanced Flexibility

Adaptability is another hallmark of today’s advanced מקל חם טלסקופי solutions. Traditional hot sticks were fixed-length, limiting their reach and application. In contrast, telescopic versions feature interlocking segments that can be extended or retracted as needed. This design supports a broad range of applications, from simple switch operations to intricate maintenance of high-altitude transmission lines.

עם ה- telescopic hot stick, mobility and storage are also greatly improved. Workers can easily transport these tools in utility vehicles, minimizing space usage. Once deployed, the telescopic system locks securely into place, maintaining full rigidity and safety during use. Utility professionals appreciate the balance of portability and reach, especially in hard-to-access locations or during emergency repairs. Whether conducting voltage testing or installing insulating sleeves, this advanced tool adapts to nearly every jobsite condition.

Durability and Longevity for Demanding Field Conditions

Utility work is often performed in harsh outdoor environments, and tools must withstand a wide range of weather conditions without compromising performance. The high voltage hot stick is built for rugged durability, combining high-strength materials with corrosion-resistant coatings. These enhancements prevent degradation from UV exposure, moisture, or extreme temperatures—common threats in field applications.

Beyond physical wear, dielectric integrity is essential for long-term reliability. Even after years of usage, well-maintained hot stick electrical tools continue to deliver optimal insulation, provided they are cleaned and tested according to industry protocols. Many models come with hydrophobic surfaces to repel moisture and reduce conductivity, improving performance during rainy or humid weather. This robust construction translates into fewer tool replacements, lower maintenance costs, and improved safety records over time.

Versatility in Utility Applications

One of the most compelling reasons for investing in מקל חם טלסקופי equipment is its versatility across utility functions. These tools are compatible with a range of interchangeable heads and adapters, enabling technicians to perform a variety of tasks from a single platform. Whether it's testing voltage, applying grounding equipment, operating switches, tightening hardware, or removing animal guards, these sticks can be outfitted for the specific task at hand.

In urban substations or remote rural settings, the hot stick electrical remains a dependable companion. Telescopic variants offer precise control over reach, allowing linemen to navigate tight clearances or span wide distances with equal ease. The ability to quickly change attachments means crews spend less time switching tools and more time executing critical work. As a result, job efficiency and system reliability both benefit from this multifunctional approach.

Hot stick electrical FAQs

What is a hot stick and why is it important for electrical safety?

A hot stick electrical tool is a long, insulated pole used by electric utility workers to handle high-voltage equipment from a safe distance. It is essential for preventing electrical shock, allowing operators to perform live-line work such as opening switches, replacing fuses, or installing equipment without directly contacting energized parts. By keeping a safe working distance, the hot stick reduces the chance of electrical arc or physical injury, making it an irreplaceable tool in the power distribution sector.

How does a telescopic hot stick differ from a standard hot stick?

ה telescopic hot stick features a modular design that allows it to extend or collapse depending on the application. This offers greater flexibility over traditional fixed-length sticks. Telescoping models are especially useful in scenarios where variable distances need to be covered or when storage space is limited. They are constructed with locking mechanisms that ensure secure extension during use, offering the same level of dielectric protection as non-collapsible sticks while adding convenience and adaptability.

In what situations should a high voltage hot stick be used?

ה high voltage hot stick is specifically designed for operations involving voltages typically exceeding 15kV. It should be used in environments such as transmission towers, substations, and overhead line maintenance. These sticks provide critical protection in high-risk scenarios where direct contact would be dangerous or fatal. Whether used for testing circuits, isolating faults, or conducting emergency interventions, the high voltage hot stick is vital for safety and operational success.

How should hot stick tools be maintained to ensure safety?

Proper maintenance of hot stick electrical tools includes regular cleaning with approved solvents, visual inspections for cracks or contamination, and periodic dielectric testing as recommended by industry standards. Storing the tools in protective cases or sleeves helps prevent environmental damage. Maintenance routines are crucial for ensuring the insulation properties remain intact, as even a small imperfection can compromise the tool’s effectiveness in live-line work.

Can hot stick equipment be used in wet or humid conditions?

Yes, but with caution. While many telescopic hot stick tools are designed with hydrophobic coatings to resist moisture, wet conditions still present a higher risk of conductivity. Workers should follow strict guidelines and conduct thorough tool testing before using hot sticks in such environments. Some models are engineered for improved performance in damp conditions, but best practices still dictate postponing work during heavy rain or using additional insulating measures when safety is uncertain.

חדשות אחרונות

Hydraulic Crimping Tool – Precision & Heavy-Duty Speed

חֲדָשׁוֹתNov.05,2025

Cable Pulling Swivel | High-Strength, Anti-Twist, Stainless

חֲדָשׁוֹתNov.04,2025

Cable Pulling Tools – Pro-Grade, Safe, Fast Install

חֲדָשׁוֹתNov.03,2025

Hydraulic Crimping Tool – Fast, Precise, Quick-Change Dies

חֲדָשׁוֹתNov.02,2025

Hydraulic Crimping Tool for Sale | Fast, Precise, Heavy-Duty

חֲדָשׁוֹתNov.01,2025

Duct Rodder for Sale – Non-Conductive, Durable Fiberglass

חֲדָשׁוֹתOct.31,2025