Oct . 06, 2025 00:35 Back to list

Hot Stick: Lightweight, Insulated, Durable—Ready to Work?

High Voltage Telescoping Triangle Hot Stick: field notes, hard data, and what crews really want

If you work around energized equipment, a hot stick isn’t “nice-to-have”—it’s the difference between a safe shift and an incident report. I’ve watched distribution crews lean on telescoping triangle designs for years; the geometry prevents spin, which sounds minor until you’re hanging a cutout in a crosswind at dusk. This China-made High Voltage Telescoping Triangle hot stick leans into that reality: epoxy resin + fiberglass, long reach, fast locks, and frankly, fewer surprises.

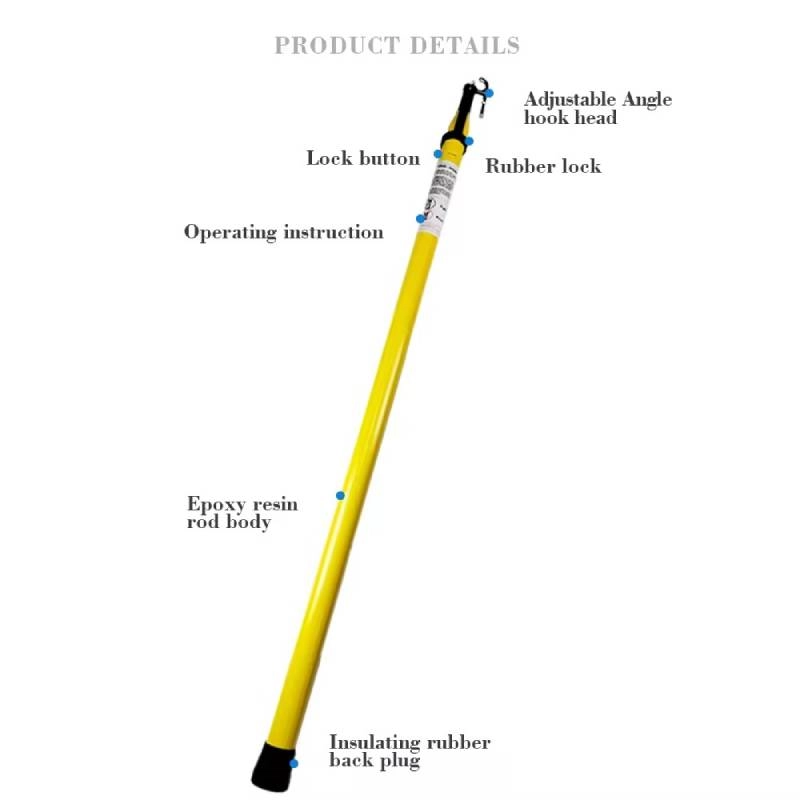

What’s inside the pole (and why it matters)

Core materials are epoxy resin and high-quality fiberglass, pultruded and then cured. The outer layer typically carries a UV-stable, hydrophobic gelcoat to keep moisture at bay. Triangle telescoping sections reduce twist under torque—handy when tightening hardware or manipulating switches. With the right head, a hot stick lets you test voltage, tighten nuts and bolts, apply tie wires, open/close switches, replace fuses, or sleeve conductors without getting dangerously close.

Process flow and testing (short version)

- Materials: E-glass fiber, epoxy resin; UV gelcoat exterior.

- Methods: Pultrusion → sanding → hydrophobic coating → assembly of telescopic sections → universal head fitment → quality checks.

- Testing standards: ASTM F711 (dielectric/mechanical), IEC 60855-1 and IEC 61235 (live working), IEEE 516 (work practices), OSHA 1910.269 (utility safety).

- Typical test data: dielectric withstand ≈100 kV/ft dry, ≈75 kV/ft wet (lab conditions); bending strength ≈600–800 MPa; torque resistance depends on section size—triangle profile helps a lot.

- Service life: around 8–12 years with maintenance (cleaning, waxing, and periodic dielectric testing); real-world use may vary.

- Certifications: usually ISO 9001 plant + third-party dielectric tests; ask for latest reports.

Product snapshot and specs

Here’s a representative spec for the High Voltage Telescoping Triangle hot stick (actual configurations vary by length and section count):

| Material | Epoxy resin + fiberglass, UV-stable gelcoat |

| Shape / Sections | Triangle telescoping; 4–8 sections (options) |

| Extended Length | ≈4.5–9.0 m options; custom lengths available |

| Retracted Length | ≈1.6–2.2 m (depends on sections) |

| Head / Tip | Universal spline; 5/8"-11 adapter optional |

| Dielectric Withstand | ≥100 kV/ft dry; ≥75 kV/ft wet (ASTM F711 method) |

| Weight | ≈3.5–6.5 kg depending on build |

| Compliance | ASTM F711, IEC 60855-1 / 61235, OSHA 1910.269 (usage) |

Where crews use it (and the perks)

- Distribution switching, fuse replacement, cutout installation, voltage detection.

- Laying insulating sleeves, applying tie wires, operating overhead switches.

- Industries: electric utilities, EPCs, rail electrification, substations, wind/solar O&M, industrial plants.

Advantages that keep coming up in feedback: anti-spin control from the triangle profile, positive section locks for speed, a non-slip grip even with gloves, and coatings that shed water. Many customers say the glide between sections is “satisfyingly smooth,” which, surprisingly, makes a long shift feel shorter.

Vendor landscape (quick comparison)

| Vendor | Origin | Lead Time | Certs/Tests | Customization |

|---|---|---|---|---|

| Bilopowtel Triangle Hot Stick | China | ≈2–4 weeks (stock-dependent) | ISO 9001 facility; ASTM/IEC test reports available | Length, sections, heads, color, branding |

| Vendor A (Triangle) | US/EU | ≈3–6 weeks | ASTM/IEC; broad accessory ecosystem | Wide; premium price tier |

| Vendor B (Round) | Global | ≈4–8 weeks | Meets basics; fewer torque perks | Standard lengths; limited heads |

Customization and maintenance

Options include section count, extended length, universal spline vs. 5/8"-11 head, orange/yellow colorways, dielectric branding, and tool-end kits. For upkeep: clean with approved hot stick wipes or isopropyl alcohol, inspect locks/tips, wax the surface periodically, and schedule dielectric tests at intervals per your utility policy (many go 6–12 months).

Two quick field stories

Mountain crew, 15 kV line: they used a 7.5 m triangle hot stick to replace a blown fuse link above a steep right‑of‑way. The anti-spin kept the cutout steady while gusts came through the saddle. Time-on-task dropped by ~20%, according to the foreman.

Solar substation O&M: operators used a shorter, 4.5 m model for routine switch operations and voltage checks. “It’s quick to deploy and doesn’t chatter when torqued,” one tech told me—brief, but telling.

Bottom line

For crews that prize reach, speed, and control, a telescoping triangle hot stick is hard to beat. Just match the section count to your work envelope, keep the surface clean, and insist on current ASTM/IEC test documentation before you sign off.

Authoritative citations

- ASTM F711 – Standard Specification for Fiberglass-Reinforced Plastic Rod and Tube Used in Live Line Tools.

- IEC 60855-1 – Live working – Insulating foam-filled tubes and solid rods.

- IEC 61235 – Live working – Insulating hollow tubes for electrical purposes.

- IEEE Std 516 – Guide for Maintenance Methods on Energized Power Lines.

- OSHA 1910.269 – Electric Power Generation, Transmission, and Distribution.

Latest news

Hydraulic Crimping Tool – Precision & Heavy-Duty Speed

NewsNov.05,2025

Cable Pulling Swivel | High-Strength, Anti-Twist, Stainless

NewsNov.04,2025

Cable Pulling Tools – Pro-Grade, Safe, Fast Install

NewsNov.03,2025

Hydraulic Crimping Tool – Fast, Precise, Quick-Change Dies

NewsNov.02,2025

Hydraulic Crimping Tool for Sale | Fast, Precise, Heavy-Duty

NewsNov.01,2025

Duct Rodder for Sale – Non-Conductive, Durable Fiberglass

NewsOct.31,2025