Oct . 21, 2025 12:50 Back to list

Cable Pulling Tools: Durable, Safe & High-Efficiency Kits

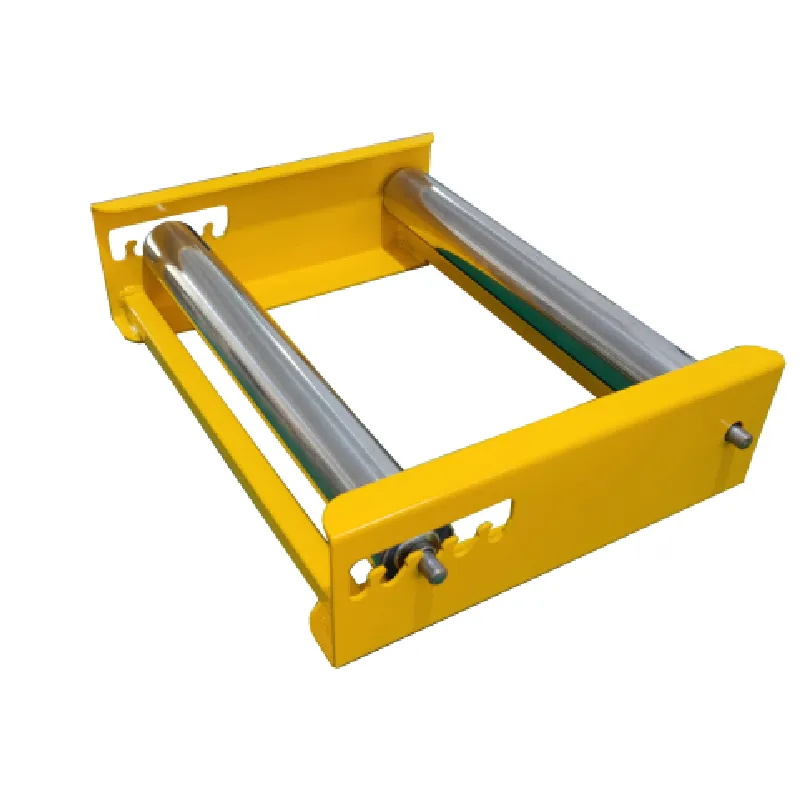

Field Notes on the Cable Drum Roller Dispenser: the quiet workhorse behind modern pulls

If you work with Cable Pulling Tools, you already know the unsung star is the cable drum roller dispenser. It’s the difference between a clean, controlled pay-off and a tangle that eats half a day. I’ve watched crews shave hours simply by switching to a stable, low-friction frame with real bearings. Sounds basic, yet it’s where projects either glide or grind.

What’s trending on job sites

Three shifts stand out: sealed bearings (less grit, lower start-up torque), modular frames that fold for vans and lifts, and safety add-ons—brakes, axle retainers, and toe guards. In telecom and renewable buildouts, crews are pushing heavier drums and tighter corridors, so stability and ground pressure distribution matter more than ever. Many customers say a good frame saves them “one headache per pull,” which is a very human KPI, I guess.

Typical specs (real-world values, not brochure dreams)

| Model | Cable Drum Roller Dispenser |

| Origin | China |

| Rated Load | ≈ 1–3 t (real-world use may vary by drum width) |

| Drum Width/Ø | Up to ≈ 1.2–1.6 m width, ≈ 2.2 m Ø |

| Frame/Finish | Welded steel, powder coat (salt spray ≈ 240 h) |

| Bearings | Sealed roller bearings; start torque ≈ 0.6–1.0% of drum weight |

| Service Life | ≈ 5–10 years with periodic inspection |

| Cert/Compliance | Factory ISO 9001, CE self-declaration, safety per EN ISO 12100 |

Process, testing, and the boring stuff that keeps you safe

Materials: welded structural steel, laser-cut plates, MIG seams; surfaces blasted then powder-coated. Methods: axle seats trued to reduce runout; bearings pressed to spec. Testing: 1.5× rated static load hold (8 h), dynamic spin cycles ≥ 1,000 with no abnormal noise, coating salt-spray ≈ 240 h (ISO 9227), dimensional checks ±1.5 mm. We’ve seen axial runout kept under ≈ 1.2 mm—good enough that cable lays stay smooth. In fact, crews report fewer snags when pairing these with low-friction bends and proper reel brakes.

Where it earns its keep

- Building MEP rooms and corridors (tidy pay-off, zero twist).

- Utility and MV cable projects adhering to IEC 60364 practices.

- Fiber backbones and data centers; paired with pulling eyes and tension meters.

- Industrial plants: trays, conduits, and long straight pulls with minimal crew.

Vendor snapshot (indicative)

| Vendor | Load Rating | Lead Time | Customization | Certs |

|---|---|---|---|---|

| Bilopowtel (China) | ≈ 1–3 t | 2–4 wks | Width, axle, brake, finish | ISO 9001, CE |

| Global Brand A | ≈ 1–2 t | Stock/2 wks | Limited options | ISO 9001 |

| Regional Fabricator B | ≈ 0.8–1.5 t | 3–6 wks | Custom frame sizes | ISO 9001 (varies) |

Customization that actually matters

Brake kits, spindle lengths, interchangeable cones, forklift pockets, grounding lugs, and even color-coding by cable type. For Cable Pulling Tools, small tweaks like low-start-torque bearings or wider stances deliver outsized gains on polished floors or rough pads.

Two quick case notes

- Data hall fit-out: 1.2 km of 240 mm² feeders; swapping to a wider base dispenser cut crew count from 6 to 5, time down ≈ 18%.

- Fiber street run: narrow sidewalks; folding frame cleared access rules, zero incidents, inspector happy (surprisingly rare).

Feedback? Many customers say the big win is consistency: predictable pay-off tension and fewer bruised knuckles. However, they also warn—always chock the frame and confirm drum cone lock before lift.

Standards and safety pointers

Reference IEC 60364 for installation practices; verify conductor specs per IEC 60228; treat the frame as work equipment under EN ISO 12100 risk assessment. On U.S. sites, coordinate with OSHA 1926 for site safety. To be honest, most incidents I’ve seen were preventable—improper chocking, no brake on a slope, or a drum not centered.

Citations

- IEC 60364 Low-voltage electrical installations.

- IEC 60228 Conductors of insulated cables.

- EN ISO 12100 Safety of machinery — Risk assessment and risk reduction.

- ISO 9227 Corrosion tests in artificial atmospheres — Salt spray tests.

- OSHA 29 CFR 1926 Safety and Health Regulations for Construction.

Latest news

Hydraulic Crimping Tool – Precision & Heavy-Duty Speed

NewsNov.05,2025

Cable Pulling Swivel | High-Strength, Anti-Twist, Stainless

NewsNov.04,2025

Cable Pulling Tools – Pro-Grade, Safe, Fast Install

NewsNov.03,2025

Hydraulic Crimping Tool – Fast, Precise, Quick-Change Dies

NewsNov.02,2025

Hydraulic Crimping Tool for Sale | Fast, Precise, Heavy-Duty

NewsNov.01,2025

Duct Rodder for Sale – Non-Conductive, Durable Fiberglass

NewsOct.31,2025