Oct . 16, 2025 12:05 Back to list

Hot Stick | Insulated Telescopic Fiberglass, ASTM Rated

High Voltage Telescoping Triangle Hot Stick: field notes, specs, and buying tips

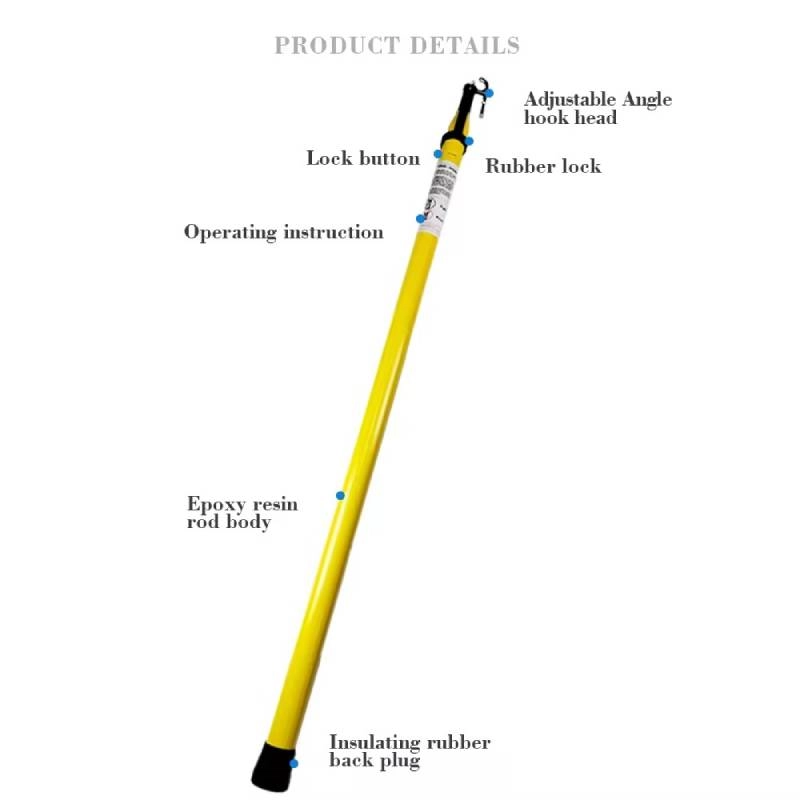

In live-line maintenance, the humble hot stick often decides whether a shift ends safely and on time. This model—High Voltage Telescoping Triangle Hot Stick, made in China—combines epoxy resin with high‑quality fiberglass, and it shows. It’s built for long reach, speed, and safety, with a triangular anti‑twist design that crews keep asking for. Depending on the head you mount, you can test for voltage, tighten hardware, switch, replace fuses, apply tie wires, even sleeve lines—without stepping into the arc of trouble.

What’s changing across the industry

Utilities are pushing more live-line work to cut outages—no surprise there. The trend is toward telescoping triangle bodies (less twist, faster indexing), hydrophobic UV coatings, and modular heads. Some fleets now add RFID to track inspection cycles. Honestly, the biggest shift is cultural: more crews expect tools that are light, fast, and predictable in the rain.

Construction, process, and test standards

- Materials: dielectric-grade epoxy matrix with E‑glass reinforcement; non‑conductive composite collars; silicone grip.

- Method: pultruded triangular tubes, precision‑mated telescoping sections, mechanical lock buttons; UV‑stable clear coat.

- Validation: dielectric withstand and leakage per ASTM F711 and IEC 60855‑1; telescoping integrity per ASTM F1826; periodic wipe tests and bend/torque checks; OSHA 1910.269 work-practice alignment.

- Service life: ≈10–15 years with proper cleaning, inspection, and storage; real‑world use may vary by climate and workload.

- Industries: transmission and distribution, substation maintenance, rail electrification, wind and solar O&M, industrial facility power.

Representative specifications

Numbers below are typical for a telescoping triangle hot stick. Always confirm final spec with the vendor before procurement.

| Parameter | Typical Value (≈) |

|---|---|

| Extended length | 4.8–7.5 m (16–25 ft) |

| Collapsed length | 1.6–2.1 m (5.2–7 ft) |

| Sections | 3–7 sections, triangular anti‑twist |

| Mass | 3.0–5.5 kg depending on length |

| Dielectric strength | ≥100 kV/ft dry; ≥75 kV/ft wet (lab), per ASTM F711 |

| End fitting | Universal spline for heads: hooks, sockets, voltage detectors, fuse tools |

| Surface finish | UV‑resistant, hydrophobic clear coat; wipe‑clean |

| Standards | ASTM F711, ASTM F1826, IEC 60855‑1; OSHA 1910.269 use |

Where it shines (and how crews use it)

- Distribution switching and recloser ops—fast indexing means fewer missed motions.

- Fuse replacement on energized lines, with a clean, stiff reach.

- Applying tie wires and insulating sleeves; hardware tightening on poles and in yard.

- Voltage presence checks using detector heads before any approach.

Field feedback: “Grip is confident even gloved,” one foreman told me; another mentioned the triangle profile made “lining up the head in the wind” easier. To be honest, that anti‑twist detail is a bigger deal than brochures let on.

Vendor snapshot (approximate)

| Vendor | Cross‑section | Standards | Lead time (≈) | Customization | Notes |

|---|---|---|---|---|---|

| Bilopowtel (China) | Triangular telescoping | ASTM F711/F1826, IEC 60855‑1 | 3–6 weeks | Length, heads, color/logo, kits | Strong value; OEM/ODM friendly |

| Hastings | Triangular/round | ASTM/IEC | 4–10 weeks | Broad accessory ecosystem | Premium pricing |

| Hubbell Chance | Triangular | ASTM/IEC | 4–8 weeks | Utility standard kits | Wide utility adoption |

Customization, maintenance, and real cases

Options include section count, lengths, universal head kits, dielectric color coding, private label, and carry bags. Keep the hot stick clean with approved silicone wipes; store dry, away from UV; re‑test annually (or per utility policy) for dielectric performance and mechanical integrity.

Case note 1: A Midwestern utility swapped older round models for a triangular telescoper—average switching time dropped ≈18% on windy spans, with fewer alignment retries. Case note 2: A Southeast Asia contractor reported minimal fiber bloom after a monsoon season, crediting the UV/hydrophobic coat. Anecdotal, yes, but consistent with what I’ve seen.

Certifications typically include ISO 9001 for manufacturing and third‑party lab reports to ASTM/IEC. Request current test sheets; don’t skip that step.

Bottom line

If you want a fast, anti‑twist hot stick with credible standards backing and room to customize, this telescoping triangle design is an easy shortlist pick. As always, match length and head kit to your switching and fuse workflow—and test, test, test.

- ASTM F711 – Standard Specification for FRP Rod and Tube Used in Live Line Tools.

- ASTM F1826 – Standard Specification for Live Line Tool—Telescoping hot stick.

- IEC 60855‑1 – Live working—Insulating foam‑filled tubes and solid rods.

- OSHA 1910.269 – Electric power generation, transmission, and distribution.

Latest news

Hydraulic Crimping Tool – Precision & Heavy-Duty Speed

NewsNov.05,2025

Cable Pulling Swivel | High-Strength, Anti-Twist, Stainless

NewsNov.04,2025

Cable Pulling Tools – Pro-Grade, Safe, Fast Install

NewsNov.03,2025

Hydraulic Crimping Tool – Fast, Precise, Quick-Change Dies

NewsNov.02,2025

Hydraulic Crimping Tool for Sale | Fast, Precise, Heavy-Duty

NewsNov.01,2025

Duct Rodder for Sale – Non-Conductive, Durable Fiberglass

NewsOct.31,2025