-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

dets. . 07, 2024 07:50 Back to list

hot stick electrical safety

Hot Stick Electrical Safety A Critical Protocol for Power Line Workers

Electrical work is an inherently dangerous occupation, particularly when it involves high-voltage power lines. The importance of safety cannot be overstated, and one of the essential tools used to ensure the safety of linemen is the hot stick or insulated pole. These tools are crucial for protecting workers while they perform maintenance on live electrical systems. This article examines the significance of hot stick electrical safety and the measures that should be taken to mitigate risks associated with electrical work.

What are Hot Sticks?

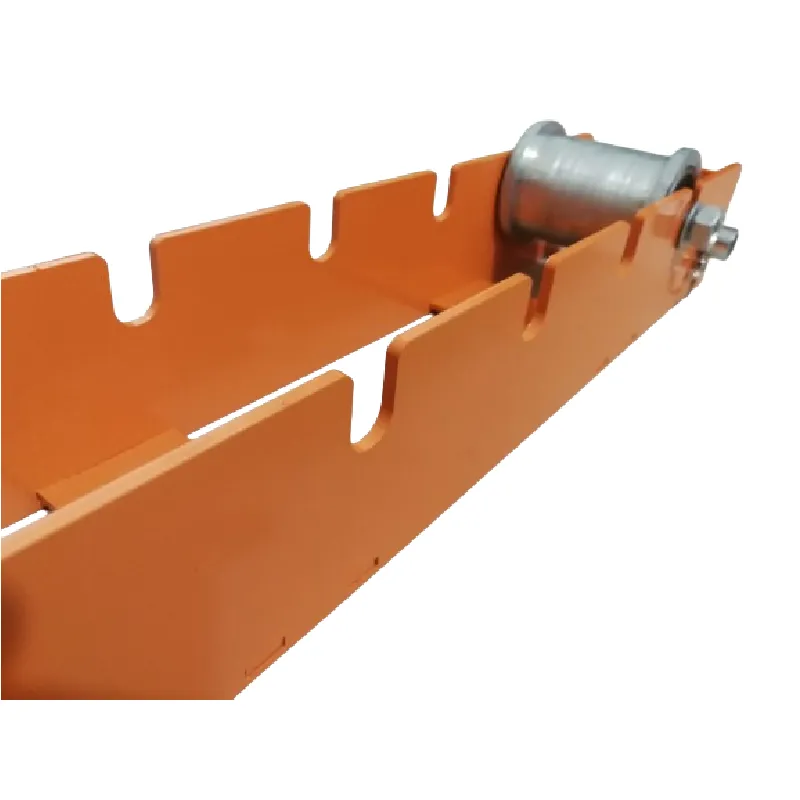

Hot sticks, also known as live-line tools or insulated poles, are specially designed tools that allow electrical workers to operate on power lines without directly contacting live wires. Typically made of fiberglass or other non-conductive materials, hot sticks extend the reach of workers, enabling them to perform tasks such as switching, voltage measurement, and repairs from a safe distance. They are essential for maintaining power systems without shutting off electricity, thereby minimizing service interruptions for customers.

The Importance of Hot Stick Electrical Safety

The potential hazards of working with live electricity are immense. Contact with high-voltage lines can lead to severe injuries or fatalities, not only for the workers directly involved but also for those in the surrounding area. Hot stick safety protocols help to ensure that linemen can perform their duties without compromising their safety. Here are several critical aspects of hot stick electrical safety

1. Proper Training Before using a hot stick, workers must undergo comprehensive training that covers the operational procedures and the electrical hazards they may encounter. Understanding how to correctly use a hot stick, the limits of these tools, and the importance of maintaining a safe distance from live wires is fundamental.

hot stick electrical safety

2. Regular Inspections and Maintenance Hot sticks should be regularly inspected for signs of wear or damage. Any cracks, dents, or signs of electrical tracking can compromise the tool's integrity, rendering it unsafe. Workers must adhere to a routine inspection schedule and replace any defective tools immediately.

3. Use of Protective Gear While hot sticks provide a barrier from electrical contact, personal protective equipment (PPE) remains essential. Workers should wear insulated gloves, helmets, and flame-resistant clothing to provide additional protection from electrical arcs or accidental contacts.

4. Understanding Electrical Fields Linemen need to be educated about the effects of electrical fields and how they can cause induction or arcing, even at a distance. Awareness of one’s surroundings and knowing the operational limits of their tools are crucial for safe practices.

5. Clear Communication Effective communication among team members during operations significantly reduces the risk of accidents. Establishing clear signals and protocols allows workers to remain aware of their environment and each other's actions, providing a layer of safety against human error.

6. Emergency Preparedness Finally, having a well-defined emergency response plan is vital. Workers should be trained in how to respond in the event of an accident, including first aid procedures for electrical shock and knowing how to contact emergency services quickly.

Conclusion

Hot stick electrical safety is a foundational element of maintaining a safe working environment for power line workers. By adhering to stringent safety protocols, undergoing proper training, conducting regular inspections, and implementing effective communication strategies, utility companies can significantly reduce the risks associated with working on live electrical lines. As technology continues to advance, it's imperative that safety measures evolve in tandem, prioritizing worker safety while ensuring the reliability of electrical services. The commitment to safety not only protects workers but also safeguards communities that depend on the vital infrastructure of electricity.

Latest news

duct-rodders-and-conduit-rod-tools

NewsAug.22,2025

ratchet-pullers-and-wire-tightening-tools

NewsAug.22,2025

chain-ratchet-pullers-and-hoist-solutions

NewsAug.22,2025

telescopic-hot-stick-for-electrical-and-high-voltage-use

NewsAug.22,2025

cable-clamp-and-insulated-cable-clamp-systems

NewsAug.22,2025

duct-rodder-conduit-rodder-and-cable-solutions

NewsAug.22,2025