-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

TEL:

0086-311-88862036

Ion . 17, 2025 05:36 Back to list

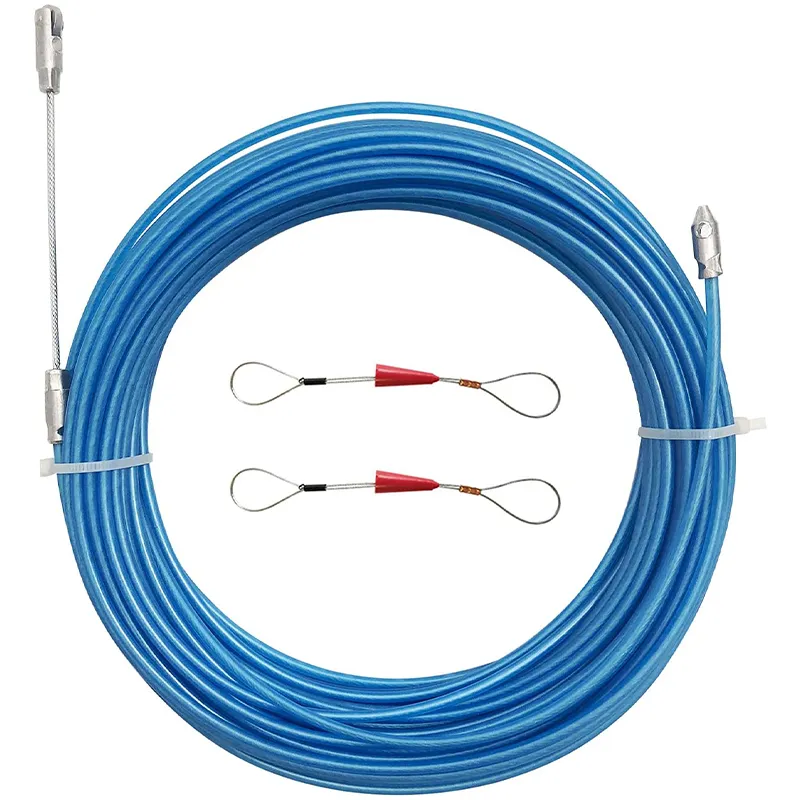

Cable Clamp

Wire grip clamps have become indispensable components in various industries, offering a versatile and reliable solution for fastening and securing cables, wires, and other materials. Their importance cannot be underestimated, particularly in fields requiring high safety standards and accuracy.

Trust is a cornerstone in the relationship between manufacturers, suppliers, and end-users of wire grip clamps. It is important to work with reputable suppliers who have a proven track record of delivering high-quality products. Trustworthiness, in this context, also extends to the transparency of product information, including detailed specifications, proper usage instructions, and support services. A transparent and customer-focused supplier can mitigate risks and enhance the confidence of users implementing these solutions. Regarding product selection, the key is to assess the specific requirements of your project. Consider factors such as the type and diameter of the wire or cable, load requirements, environmental conditions, and any regulatory or compliance standards applicable to your application. Custom solutions are also available, and expert consultation can be invaluable when unique challenges present themselves. Wire grip clamps are not merely items of hardware; they are critical enablers of complex systems functioning safely and efficiently. As our infrastructures become more sophisticated, the demand for reliable, high-performance solutions will only increase. Whether you are an engineer, a project manager, or an electrician, understanding and utilizing the appropriate wire grip clamps will ensure that your projects not only meet but exceed the standards of modern-day construction and installation. In conclusion, wire grip clamps offer a blend of functionality, reliability, and safety. Whether you are securing cables on a ship or managing wiring in a skyscraper, the right choice in wire grip clamps can make all the difference. With a keen eye for quality and a commitment to adhering to industry best practices, you can leverage these small but mighty tools to achieve superior project outcomes.

Trust is a cornerstone in the relationship between manufacturers, suppliers, and end-users of wire grip clamps. It is important to work with reputable suppliers who have a proven track record of delivering high-quality products. Trustworthiness, in this context, also extends to the transparency of product information, including detailed specifications, proper usage instructions, and support services. A transparent and customer-focused supplier can mitigate risks and enhance the confidence of users implementing these solutions. Regarding product selection, the key is to assess the specific requirements of your project. Consider factors such as the type and diameter of the wire or cable, load requirements, environmental conditions, and any regulatory or compliance standards applicable to your application. Custom solutions are also available, and expert consultation can be invaluable when unique challenges present themselves. Wire grip clamps are not merely items of hardware; they are critical enablers of complex systems functioning safely and efficiently. As our infrastructures become more sophisticated, the demand for reliable, high-performance solutions will only increase. Whether you are an engineer, a project manager, or an electrician, understanding and utilizing the appropriate wire grip clamps will ensure that your projects not only meet but exceed the standards of modern-day construction and installation. In conclusion, wire grip clamps offer a blend of functionality, reliability, and safety. Whether you are securing cables on a ship or managing wiring in a skyscraper, the right choice in wire grip clamps can make all the difference. With a keen eye for quality and a commitment to adhering to industry best practices, you can leverage these small but mighty tools to achieve superior project outcomes.

Next:

Latest news

What Are Construction Tools and How Are They Used?

NewsJul.11,2025

Professional-Grade Duct Rodding Tools for Superior Cable Installation

NewsJul.11,2025

Enhancing Safety and Efficiency with Modern Hot Stick Solutions

NewsJul.11,2025

Empowering Cable Installation with Advanced Rodder Solutions

NewsJul.11,2025

Elevate Your Cable Installation Projects with Cable Pulling Tools

NewsJul.11,2025

Efficient Cable Handling Solutions: Cable Rollers for Sale

NewsJul.11,2025

Copyright © 2025 Shijiazhuang Bilo Import and Export Trading Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

BlLo lmport & Éxport is specialized in power and cable equipment andconsiruction tools,Qur main producis are FRP

duct rodder, cable rollerscable pulling winch, cable drum jack, cable pulling sock, etc.

Copyright © 2025 Shijiazhuang Bilo Import and Export Trading Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy