- Kini nga serye nga wire grip delikado ug hapsay, makapamenos sa kadaot sa mga kable.

- The locking handles hold the jaws open for easy placement on the cable, which is easy to use.

- Stretching conductor wire, messenger wire or using in industry and agriculture.

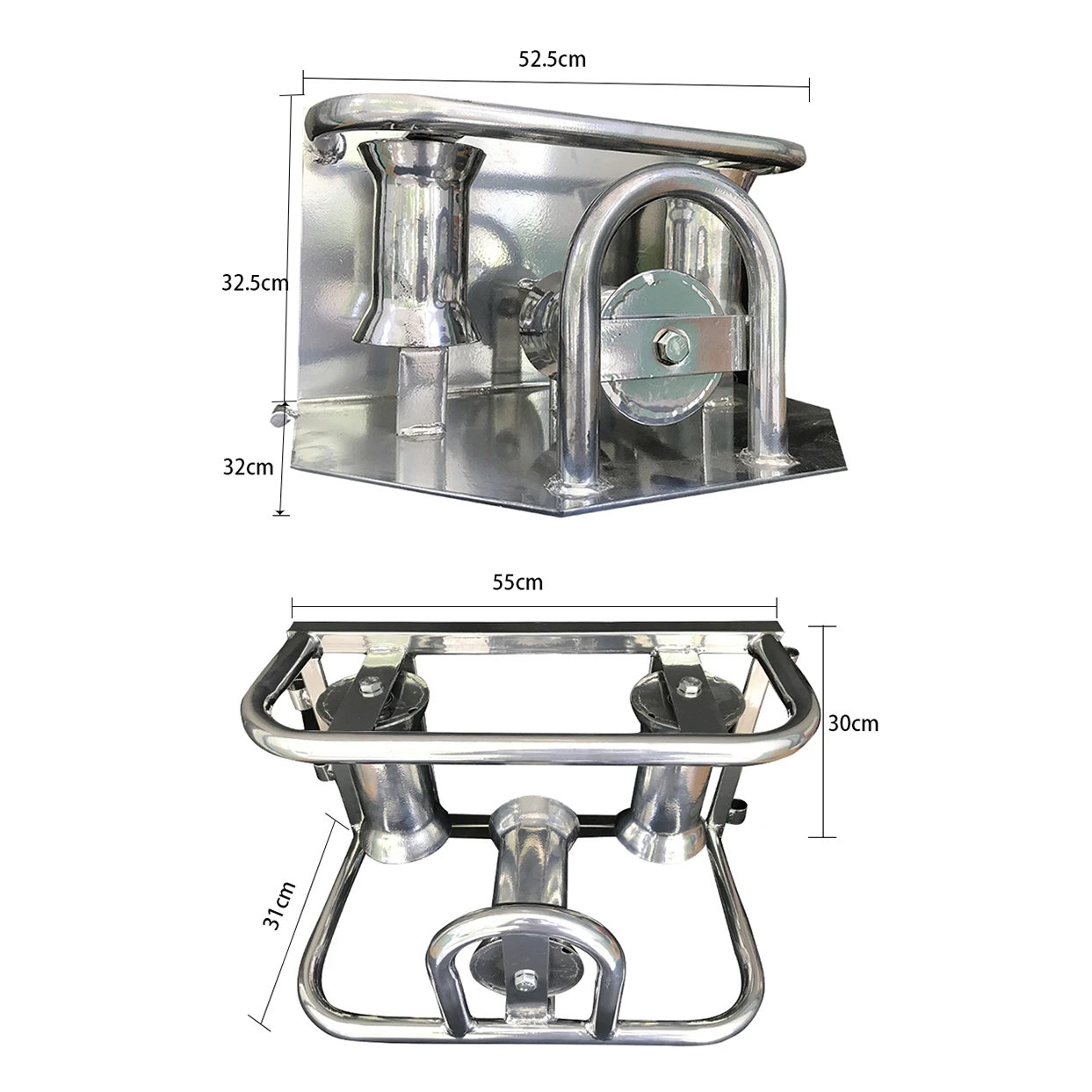

|

Product No. |

Angayan nga wire (mm) |

Kapasidad sa pagkarga (kn) |

Timbang(kg) |

|

KXRS-05 |

0.5-10 steel o tumbaga wire |

5 |

0.36 |

|

KXRS-10 |

2.5-16 steel o tumbaga wire |

10 |

0.75 |

|

KXRS-20 |

4-22 steel o copper wire |

20 |

1.25 |

|

KXRS-30 |

16-32 steel o copper wire |

30 |

2.5 |

- Materyal: Gihimo sa taas nga kalidad nga puthaw nga puthaw, nga lig-on, lig-on ug lig-on.

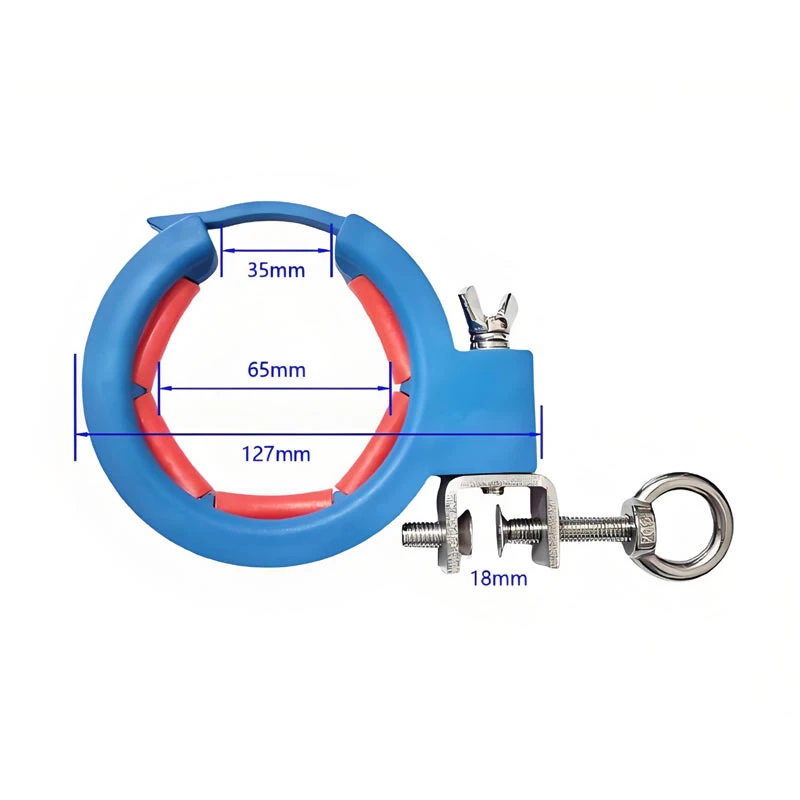

- Kapasidad sa pag-load: 0.5-3T, angay alang sa lainlain nga diametro nga kable.

- Gihimo gikan sa lainlaing mga materyales, naghatag kami og cable fish tape, metalfish tape, steel fish tape,

- Taas nga tensile: Kusog ang pagsukol, taas ang kagat, dili dali madulas ug magbag-o.

- Luwas nga himan: sa pipila ka dagkong load series, ang clamp mouth adunay himan nga locking cover aron mapadayon ang wire, nga magsiguro sa kaluwasan ug walay jumper.

- Ang tong delikado ug hapsay, makapamenos sa kadaot sa mga kable

- Sa dili pa gamiton, limpyohi ang dapit sa apapangig ug susiha ang pagkupot alang sa saktong operasyon aron malikayan ang pagkalusot.

- Dili molapas sa rated nga kapasidad.

- Kung gigamit sa / duol sa kusog nga mga linya, yuta, insulate, o ibulag ang pagkupot sa dili pa ibira.

- Ang mga grip gamiton alang sa temporaryo nga pag-instalar, dili alang sa permanenteng angkla.

- Ang ubang mga modelo gisangkapan og swing down safety latch isip standard.

How to Choose the Right Cable Clamp for Your Application

Selecting the right Cable Clamp is essential for ensuring safe, organized, and long-lasting cable management in any electrical or industrial setup. Whether used in machinery, vehicles, or construction projects, the correct clamp helps prevent cable damage, maintain system reliability, and improve overall installation efficiency. Understanding the key factors in choosing the right cable clamp can make a significant difference in performance and safety.

First, consider the cable size and diameter. A properly sized clamp should hold the cable securely without compressing or deforming it. Always check the manufacturer’s specifications to match the clamp’s inner diameter with your cable dimensions. Using an oversized or undersized clamp may lead to slippage or insulation damage.

Next, focus on the material and environment. Cable clamps are available in various materials such as nylon, stainless steel, plastic, and aluminum. For indoor applications, plastic or nylon clamps offer lightweight and cost-effective solutions. However, for outdoor or harsh environments, stainless steel clamps provide superior corrosion resistance and strength.

You should also evaluate the mounting style—options include screw-type, adhesive, or snap-lock clamps. Choose based on your installation surface and ease of maintenance. For high-vibration settings, a screw-mounted or metal clamp ensures better stability and durability.

Lastly, consider temperature and chemical resistance if your application involves extreme conditions. High-performance clamps can withstand heat, oil, or UV exposure without losing grip.

By carefully assessing size, material, mounting, and environment, you can select the ideal Cable Clamp that ensures secure, tidy, and professional cable installations across a wide range of applications.

Installation Guide: How to Properly Secure Cables with Cable Clamps

Properly securing cables is essential for both safety and efficiency in electrical, industrial, and construction projects. Using a Cable Clamp ensures that wires and cables are organized, protected from damage, and remain in place over time. Following the correct installation steps can help prevent accidents, reduce wear, and maintain system reliability.

Begin by selecting the appropriate cable clamp based on the size, type, and environment of the cables. Ensure the clamp’s diameter matches the cable bundle, and choose a material suitable for your installation conditions—plastic or nylon clamps are ideal for indoor use, while stainless steel or metal clamps are better for outdoor or high-vibration environments.

Next, position the cables along the desired path. Avoid sharp bends or tension that could strain the wires. Place the clamp around the cable bundle and align it with a secure mounting surface, such as a wall, panel, or equipment frame. If the clamp is screw-mounted, mark the drilling points carefully to prevent misalignment.

When fastening the clamp, apply steady, even pressure. Do not overtighten, as excessive force can damage cable insulation or deform the clamp. For adhesive or snap-lock clamps, ensure the surface is clean and dry before securing, allowing proper adhesion or locking.

For long cable runs, use multiple clamps spaced evenly to support the cables adequately and prevent sagging. Regularly inspect the installed clamps to ensure they remain tight and free of wear, especially in high-vibration or outdoor applications.

By following these steps, professionals can achieve a neat, safe, and durable cable installation. Proper use of Cable Clamps not only protects cables from mechanical stress but also improves accessibility for maintenance and enhances overall system organization.

Different Types of Cable Clamps and Their Industrial Applications

Cable Clamps are essential components for organizing, securing, and protecting cables in a wide range of industrial and commercial applications. Selecting the right type of clamp ensures safety, efficiency, and long-term reliability in electrical installations. There are several types of cable clamps, each designed for specific purposes and environments.

1.Plastic or Nylon Cable Clamps: Lightweight and cost-effective, these clamps are ideal for indoor use and low-voltage wiring. They resist corrosion and are easy to install, making them suitable for office buildings, residential wiring, and light industrial setups.

2. Stainless Steel Cable Clamps: Known for their strength and durability, stainless steel clamps are perfect for harsh environments. They resist corrosion, high temperatures, and chemical exposure, making them ideal for marine, outdoor, and industrial machinery applications.

3. Rubber-Lined or Cushion Clamps: These clamps have a protective rubber lining to prevent cable abrasion and vibration damage. They are widely used in automotive, aerospace, and heavy machinery industries where cables are exposed to constant movement or vibration.

4. Screw-Mounted or Bolt-On Clamps: Designed for secure mounting on walls, panels, or equipment frames, these clamps provide a stable and permanent solution for cable management in factories, electrical control rooms, and construction projects.

5. Adhesive or Snap-On Clamps: Easy to install without tools, these clamps are suitable for lightweight cables and temporary installations. They are often used in home electronics, office setups, and small-scale wiring projects.

By understanding the different types of cable clamps and their specific applications, engineers and installers can select the most suitable solution for each project. Using the right clamp improves cable organization, prevents mechanical damage, and ensures a safer, more reliable industrial environment. Proper clamp selection is key to maintaining system integrity and operational efficiency across a variety of industries.