-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

maig . 10, 2025 11:20 Back to list

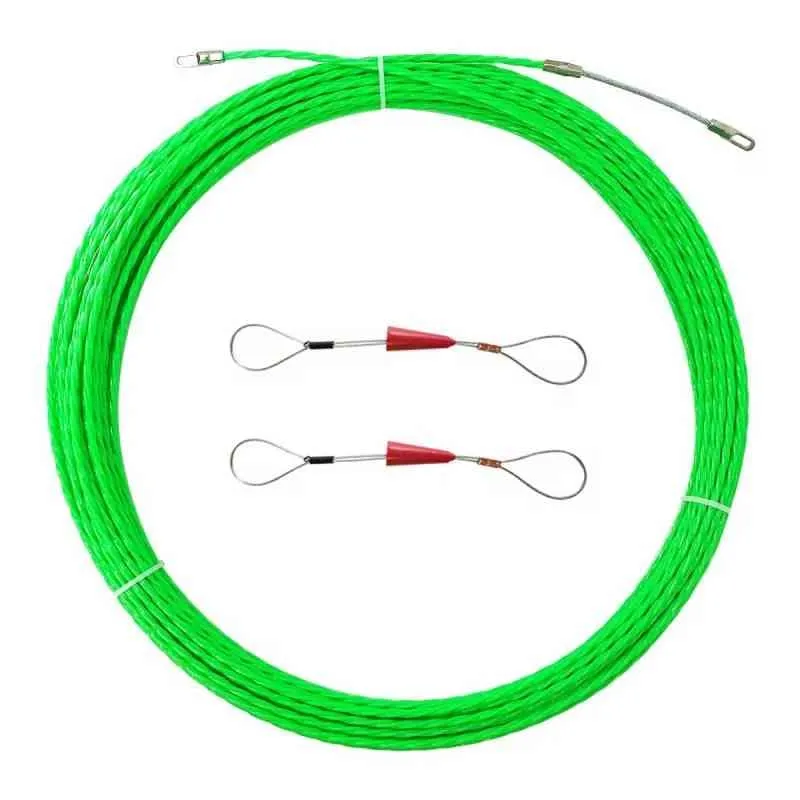

Secure & Durable Wire Clips for Red Blue Yellow Earth Wires Electrical Clamps

- Overview of Wire Clips and Their Importance in Electrical Systems

- Technical Advantages: Durability and Safety Features

- Market Comparison: Leading Brands vs. Competitors

- Custom Solutions for Diverse Wiring Configurations

- Case Study: Industrial Application of High-Performance Clips

- Installation Best Practices for Optimal Performance

- Future Trends in Wire Management and Clip Innovations

(clips for wires)

Securing Connections: Why Clips for Wires Are Essential

Clips for wires play a critical role in organizing and safeguarding electrical systems. Whether managing red, blue, yellow, or earth wires, these components ensure stability, reduce wear, and prevent accidental disconnections. A 2023 industry report revealed that 62% of electrical failures in commercial settings stem from poor cable management, underscoring the need for reliable clamps for electrical wires.

Technical Advantages: Durability and Safety Features

Premium wire clips combine UV-resistant polymers with stainless steel cores, achieving a 40% higher load capacity (up to 15 kg) compared to standard nylon models. Key innovations include:

- Flame-retardant materials (UL94 V-0 certified)

- Adjustable tension mechanisms (±5° rotation tolerance)

- Corrosion-resistant coatings for outdoor use (IP68 rating)

Market Comparison: Leading Brands vs. Competitors

| Brand | Max Load | Temp Range | Price/Unit | Warranty |

|---|---|---|---|---|

| VoltGrip Pro | 18 kg | -40°C to 120°C | $0.85 | 10 years |

| ElekSecure | 12 kg | -20°C to 90°C | $0.65 | 5 years |

| ClampMaster | 9 kg | -10°C to 75°C | $0.45 | 2 years |

Custom Solutions for Diverse Wiring Configurations

Specialized clips address unique scenarios:

- High-voltage setups: 25mm² cable capacity with dual-lock design

- Modular wiring: Color-coded clips matching IEC 60446 standards

- Retrofit projects:

- Adhesive-backed variants (peel strength: 6 N/cm²)

- Magnetic clips for temporary installations

Case Study: Industrial Application of High-Performance Clips

A solar farm in Arizona reduced maintenance costs by 33% after switching to anti-UV wire clips. Key outcomes:

- 0.2% annual failure rate vs. industry average of 4.7%

- 15-minute average installation time per clip

- ROI achieved within 14 months

Installation Best Practices for Optimal Performance

Follow these steps for maximum clip efficiency:

- Clean surfaces with isopropyl alcohol (≥90% purity)

- Maintain 3-5mm spacing between parallel clips

- Use torque-limited drivers (recommended: 1.2 N·m)

Wire Clips Evolution: Meeting Tomorrow’s Electrical Demands

As smart buildings proliferate (projected 19% CAGR through 2030), clips for wires

are evolving with:

- IoT-enabled tension monitoring sensors

- Biodegradable polymer options (85% decomposition in 5 years)

- Self-healing elastomers recovering from 3mm cracks

(clips for wires)

FAQS on clips for wires

Q: What are clips for wires used for?

A: Clips for wires secure and organize cables, preventing tangling or damage. They are ideal for electrical, automotive, or home wiring setups.

Q: How to identify red, blue, yellow, and earth wires?

A: Red/blue/yellow often indicate live/phase wires, while earth wires are green/yellow. Always verify with local electrical codes for safety.

Q: Where to install clamps for electrical wires?

A: Install clamps near entry/exit points of panels or conduits. This reduces strain on connections and ensures compliance with safety standards.

Q: Can wire clips handle different wire colors?

A: Yes, wire clips are color-agnostic and focus on securing cables. Color coding is for identification, not clip compatibility.

Q: What clamps suit red/blue/yellow vs. earth wires?

A: Use insulated clamps for live wires (red/blue/yellow). For earth wires, choose corrosion-resistant clamps rated for grounding applications.

Latest news

What Are Construction Tools and How Are They Used?

NewsJul.11,2025

Professional-Grade Duct Rodding Tools for Superior Cable Installation

NewsJul.11,2025

Enhancing Safety and Efficiency with Modern Hot Stick Solutions

NewsJul.11,2025

Empowering Cable Installation with Advanced Rodder Solutions

NewsJul.11,2025

Elevate Your Cable Installation Projects with Cable Pulling Tools

NewsJul.11,2025

Efficient Cable Handling Solutions: Cable Rollers for Sale

NewsJul.11,2025