-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

TEL:

0086-311-88862036

jan . 19, 2025 05:20 Back to list

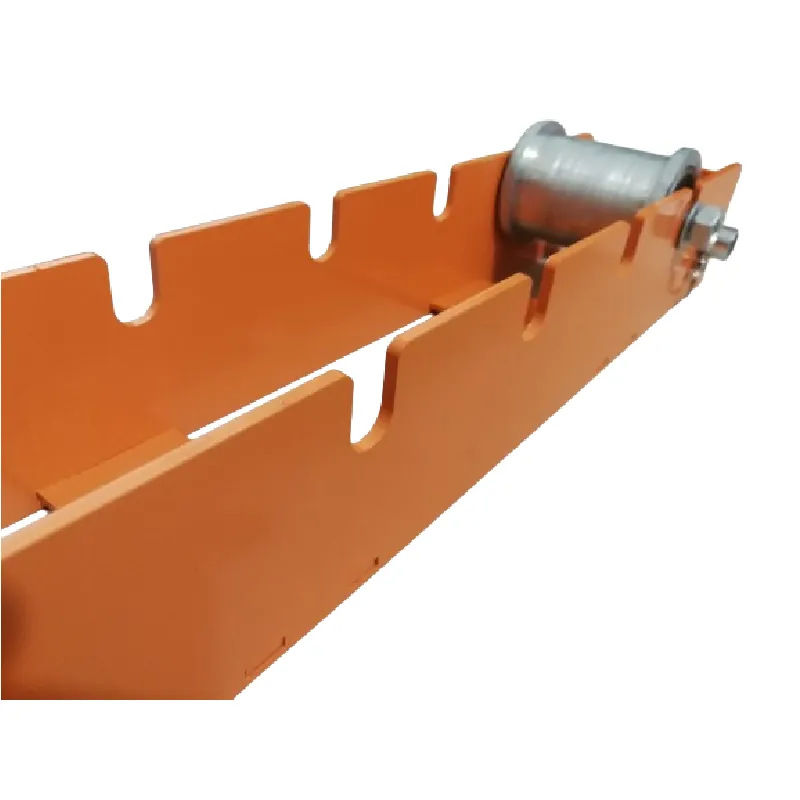

Cable Clamp

In the realm of welding, ensuring safe and efficient connections is paramount, and welding cable clamps play a critical role in this task. These indispensable tools are engineered to provide secure and stable connections between cables, allowing for optimal current flow and preventing electrical failures that can compromise welding quality and safety.

Maintenance is a cornerstone of trustworthiness in using welding cable clamps. Even the most advanced clamp designs require regular inspection and maintenance to function optimally. Professionals recommend routine checks to ensure no rust or wear compromises mechanical strength or electrical conductivity. Keeping a maintenance log can enhance accountability and provide valuable insights into the lifespan of your equipment, optimizing replacement schedules. For those involved in intense and prolonged welding activities, having a comprehensive kit of welding cable clamps is wise. Different projects might demand different clamp sizes and strengths, and versatility in your toolkit can lead to superior operational efficiency and safety. Having a variety of clamps handy ensures preparedness for any welding challenge, emphasizing both expertise and readiness. In-depth knowledge of welding cable clamps—beginning with an understanding of the fundamental principles of electrical connectivity and moving to practical application in varying conditions—enables users to harness their full potential. Engaging in certified training programs can significantly enhance a welder’s ability to select and install these clamps effectively, thereby elevating both skill and safety standards. In conclusion, welding cable clamps are not mere accessories but are central to the efficacy and safety of welding operations. Their reliability is intertwined with both the quality of the product and the expertise of the user. By understanding the nuances of these clamps and continually practicing best installation and maintenance methods, welders can ensure robust connections and long-lasting performance. Harnessing the full potential of welding cable clamps involves a combination of informed selection, precise installation, and diligent maintenance—practices that ultimately safeguard the quality and safety of welding endeavors.

Maintenance is a cornerstone of trustworthiness in using welding cable clamps. Even the most advanced clamp designs require regular inspection and maintenance to function optimally. Professionals recommend routine checks to ensure no rust or wear compromises mechanical strength or electrical conductivity. Keeping a maintenance log can enhance accountability and provide valuable insights into the lifespan of your equipment, optimizing replacement schedules. For those involved in intense and prolonged welding activities, having a comprehensive kit of welding cable clamps is wise. Different projects might demand different clamp sizes and strengths, and versatility in your toolkit can lead to superior operational efficiency and safety. Having a variety of clamps handy ensures preparedness for any welding challenge, emphasizing both expertise and readiness. In-depth knowledge of welding cable clamps—beginning with an understanding of the fundamental principles of electrical connectivity and moving to practical application in varying conditions—enables users to harness their full potential. Engaging in certified training programs can significantly enhance a welder’s ability to select and install these clamps effectively, thereby elevating both skill and safety standards. In conclusion, welding cable clamps are not mere accessories but are central to the efficacy and safety of welding operations. Their reliability is intertwined with both the quality of the product and the expertise of the user. By understanding the nuances of these clamps and continually practicing best installation and maintenance methods, welders can ensure robust connections and long-lasting performance. Harnessing the full potential of welding cable clamps involves a combination of informed selection, precise installation, and diligent maintenance—practices that ultimately safeguard the quality and safety of welding endeavors.

Next:

Latest news

What Are Construction Tools and How Are They Used?

NewsJul.11,2025

Professional-Grade Duct Rodding Tools for Superior Cable Installation

NewsJul.11,2025

Enhancing Safety and Efficiency with Modern Hot Stick Solutions

NewsJul.11,2025

Empowering Cable Installation with Advanced Rodder Solutions

NewsJul.11,2025

Elevate Your Cable Installation Projects with Cable Pulling Tools

NewsJul.11,2025

Efficient Cable Handling Solutions: Cable Rollers for Sale

NewsJul.11,2025

Copyright © 2025 Shijiazhuang Bilo Import and Export Trading Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

BlLo lmport & Éxport is specialized in power and cable equipment andconsiruction tools,Qur main producis are FRP

duct rodder, cable rollerscable pulling winch, cable drum jack, cable pulling sock, etc.

Copyright © 2025 Shijiazhuang Bilo Import and Export Trading Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy