-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

aug . 04, 2025 06:20 Back to list

Premium Cable Pulling Tools with AI | Boost Efficiency

Industry Trends in Cable Pulling Tools: The Backbone of Infrastructure

As global infrastructure investments escalate, the demand for high-efficiency cable pulling tools continues to rise. The market for cable pulling equipment is projected to surpass USD 1.85 billion by 2027 (Market Research Future), with CAGR expected around 6.3% during 2023–2028. Innovations like advanced cable pulling winches, ergonomic cable pulling socks, and durable cable tray rollers are addressing the needs of sectors ranging from power transmission to petrochemical, metallurgy, water supply, and intelligent construction.

The evolution is driven by the necessity for safer, faster, and more reliable cable laying—especially as data centers, smart grids, and renewables become infrastructure standards. Efficiency, corrosion resistance, weight reduction, and customizability are now primary buying criteria.

Cable Pulling Tools: Specifications & Performance Comparison

| Tool Type | Main Material | Max Pulling Capacity | Diameter Range | Weight (kg) | Key Features | Typical Applications |

|---|---|---|---|---|---|---|

| Push Pull Rods | High-flex fiberglass, TPU coating | 1,600 N | 3–15 mm | 0.8–9 | Modular, flexible, corrosion-resistant | Cable ducts, telecom, data centers |

| Cable Pulling Winch | Steel alloy, PVC, IP65 motors | 5,000–15,000 N | 8–50 mm | 34–160 | Variable speed, overload protection | Energy, construction, utilities |

| Cable Pulling Sock | Galvanized steel, nylon | 3,500 N | 10–90 mm | 0.2–1.2 | Reinforced grip, anti-slip design | Electrical, fibre cables, marine |

| Cable Tray Rollers | Zinc-plated steel, PU rollers | 2,000 N | 20–100 mm | 3.2–6 | Low-friction, quick-mount brackets | Industrial, megaplant cabling |

The above data illustrates the key considerations for selecting cable pulling tools tailored to specific project requirements.

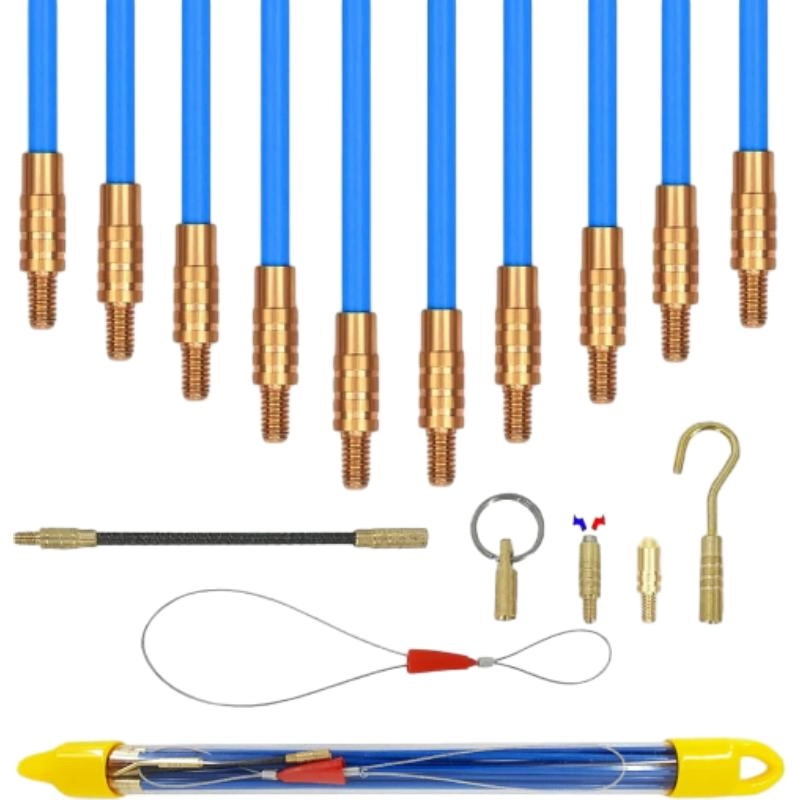

Product Spotlight: Push Pull Rods — Technical Mastery in Cable Pulling

Product Introduction

Push Pull Rods serve as the preferred solution for high-efficiency, precision cable routing across ductwork, underground conduits, data center subfloors, and telecom installations. These cable pulling tools are engineered for flexibility, tensile strength, and lightweight operation, addressing challenges in confined or complex routing scenarios.

- Product Name: Push Pull Rods

- Official Webpage: www.bilopowtel.com/push-pull-rods.html

Process Flow of Cable Pulling Tool Manufacturing

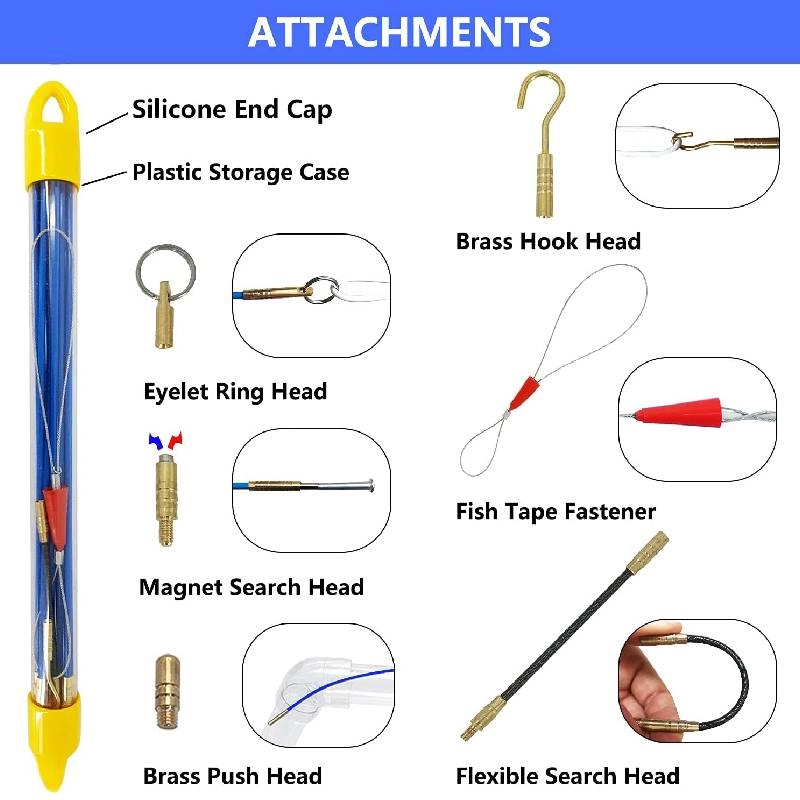

Key Features & Technical Parameters:

- Core Material: Aerospace-grade fiberglass (density ≥2.0 g/cm³)

- Coating: Industrial TPU (Shore Hardness ≥90A, UV-stabilized, -35~110°C use)

- Tensile Strength: ≥1600N (ISO/ANSI test standard)

- Bending Radius: <60 mm (6 mm/10 mm dia rod)

- Diameter Range: 3 mm, 6 mm, 9 mm, 11 mm, 15 mm (customizable)

- Available Lengths: 10 m - 150 m / set

- End Fittings: Stainless steel/Brass CNC-machined connectors

- Working Life: 10,000+ operations

- Certifications: ISO 9001, ANSI C119.1

- Corrosion and Flame Resistance: Salt Mist Test 360H, UL94-V0

- Applicable Sectors: Oil & gas, metallurgical, water utilities, energy, data cabling

Technology Advantages of Modern Cable Pulling Equipment

- High Modulus Core: Increased axial stiffness ensures rods don’t buckle in complex bends.

- Corrosion-Free Operation: TPU & fiberglass resist acids, alkalis, and saline—key for petrochemical/offshore work.

- Low-Friction Coating: Minimizes drag, speeds up installation, and extends cable sheath lifespan.

- Precision CNC End Fittings: Enhanced durability with strict tolerance mating, avoiding on-site failures.

- Modular Assembly: Multiple rods joined for long-run flexibility, reducing downtime and transport cost.

- Safety and Compliance: Compliant with ISO 9001 & ANSI C119.1—ensuring global project compatibility.

Top Manufacturers and Factory Comparison

| Manufacturer | Key Product | Core Materials | Certifications | Annual Output (sets) | Warranty | Major Market |

|---|---|---|---|---|---|---|

| BILOPOWTEL | Push Pull Rods | Fiberglass, TPU, CNC steel | ISO 9001, ANSI, TUV | 80,000+ | 3 Years | EU, USA, Asia |

| Greenlee | Cable Pulling Winch | Forged steel, aluminum | UL, CSA | 30,000 | 2 Years | NA, EU |

| Jameson | Flex Conduit Rodder | Epoxy glass, PE | ISO, ANSI | 35,000 | 2 Years | Global |

| DCD Design | Pulling Socks | Galvanized wire | CSA, RoHS | 40,000 | 1 Year | OE, CA |

BILOPOWTEL, with its Push Pull Rods, excels in international certifications, lifecycle, and material integrity, making it the go-to for demanding projects in energy, utilities, and smart infrastructure.

Visualization: Push Pull Rods Market Application Proportion

- Data Centers: Fast routing in raised access floors, stringent anti-static, and EMI control.

- Petrochemical & Offshore: Salt-corrosion resistance and explosion-proof standards justify choice.

- Power & Utilities: Used for substation, smart grid, and metro cabling; zero-failure imperative.

- Telecom: Ultra-flexibility for MDU, FTTx, and urban underground pipe cabling.

Custom Solutions for Diverse Cable Pulling Scenarios

No two cabling projects are identical—hence, custom-engineered cable pulling tools have become the industry hallmark. BILOPOWTEL’s engineering team offers on-demand adjustments to rod diameter, length, terminal adapters, and packaging, supporting on-site branding and color coding (ISO/IEC/TR 14763-2-1 standard for route identification).

- Temperature-specific compounds for Middle East or arctic installations (-35°C up to 110°C)

- Explosion-proof Rods for ATEX sites (ISO 80079-36 compliance)

- Ultra-long System Kits (up to 180 meters with quick-coupler design)

- Traceability QR codes for project documentation or maintenance history

Case Studies & Real-World Applications

Case 1: 400 kV Substation Cabling, Algeria- Challenge: Routing 285 meters of power cable in high-salinity subgrade after other tools failed from corrosion.

- Solution: Implemented heavy-duty Push Pull Rods (TPU coated) with salt-mist rating per ISO 9227.

- Result: Installation completed 38% faster, no cable sheath damage, zero breakage after 50 runs.

- Challenge: Dense raised-floor cabling, strict anti-static requirements.

- Solution: Used anti-static Push Pull Rods, modular coupler system, customized blue color code.

- Result: Delivered 2,000 rods in 12 days, error-free installation for 75,000m fiber runs.

- Challenge: Aging sewer lines, constricted and wet environments.

- Solution: Waterproof Push Pull Rods, stainless end caps, easy-clean sheathing.

- Result: Reduced downtime by 41%, improved worker safety, gained national utility certification.

Deliverables, Lead Times, and Service Guarantee

- Standard Lead Time: 7–14 days ex-works (custom: 21–28 days)

- Quality Warranty: 3 years or 10,000 operation cycles, whichever first; includes on-site/online support

- Certifications: All exports conform to ISO 9001 (2015), ANSI C119, TUV

- After-Sales: 24/7 technical hotline, free training for major accounts, local distributor support in 23 countries

FAQ: Professional Insights into Cable Pulling Tools

- 1. What main material composition is best for high-performance cable pulling rods?

- A composite of aerospace-grade fiberglass and industrial TPU coating is optimal—combining high tensile strength, flexibility, corrosion resistance, and non-conductivity, as standard in Push Pull Rods.

- 2. Which international standards are typically required for compliance in cable pulling equipment?

- Key standards include ISO 9001 (Quality Management), ANSI C119.1 (Handling/strength), UL94 (Flame resistance), and TUV (Safety/Materials verification).

- 3. What is the practical lifespan of a professional cable pulling tool in industrial use?

- When used as per ANSI recommendations, quality rods like Push Pull Rods achieve over 10,000 operation cycles or a minimum of 3–5 years, thanks to reinforced materials and strict QA.

- 4. Can cable pulling winches and push-pull rods be used together?

- Yes, they are often combined: rods navigate tight bends and start the route, while winches handle high-tension long runs, maximizing efficiency and safety.

- 5. What determines the appropriate diameter and length for a cable pulling rod?

- Selection depends on conduit/cable diameter, run length, and minimum bend radius. For dense cable packs, 6–11 mm is typical; longer underground pulls use coupled sets up to 120–180 m.

- 6. How do cable tray rollers improve the pulling process?

- Cable tray rollers allow smoother movement, protect insulation from abrasion, and reduce manual force by up to 57%, especially over long industrial runs.

- 7. Are custom labeling and OEM colors available for Push Pull Rods?

- Yes, BILOPOWTEL offers OEM/ODM, color coding per IEC14763, and laser-etching for project traceability and asset management.

Client Testimonials & Long-Term Partnerships

- Siemens Energy Europe: “The cable pulling tools from BILOPOWTEL significantly shortened our HV cable deployment and minimized sheath damage, especially in salty environments.”

- SG Utility (Singapore): “Custom Push Pull Rods from BILOPOWTEL cut installation times by 35%. Zero breakages over two years of intense use.”

- HydroItalia S.p.A.: “Exceptional corrosion and chemical resistance for our water mains project. Highly recommended for utility sectors.”

References & Further Reading (for industry credibility)

- “Cable Pulling: The Right Tools for the Right Job” — ECMWeb

- “Selection of Flexible Cable Pulling Equipment in Industrial Environments” — Cabling Installation & Maintenance Journal

- “Assessment of Modular Cable Installation Tools for Utilities” — IEEE Xplore

- “Performance Testing of Cable Pulling Winches and Tray Rollers” — ResearchGate

Latest news

What Are Construction Tools and How Are They Used?

NewsJul.11,2025

Professional-Grade Duct Rodding Tools for Superior Cable Installation

NewsJul.11,2025

Enhancing Safety and Efficiency with Modern Hot Stick Solutions

NewsJul.11,2025

Empowering Cable Installation with Advanced Rodder Solutions

NewsJul.11,2025

Elevate Your Cable Installation Projects with Cable Pulling Tools

NewsJul.11,2025

Efficient Cable Handling Solutions: Cable Rollers for Sale

NewsJul.11,2025