-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Avq . 31, 2024 08:30 Back to list

'crimping tool for hose fittings - measuring wheel'

Crimping Tools for Hose Fittings A Comprehensive Guide

When it comes to assembling hose fittings, the importance of using the right tools cannot be overstated. Among the essential tools for this task is the crimping tool. Crimping tools are designed to compress or mold a part of the hose fitting to create a secure, leak-proof connection between the hose and the fitting. This process is crucial for ensuring that hoses operate effectively in various applications, from automotive to industrial uses.

Understanding Crimping Tools

Crimping tools come in several varieties, tailored to different hose and fitting specifications. The functionality of these tools is straightforward the crimping mechanism applies pressure to the fitting and hose, causing them to fuse together tightly. This ensures optimal performance under pressure and minimizes the risk of leaks that can lead to equipment failure or accidents.

When selecting a crimping tool, consider the material and size of the hose fittings you will be working with. Different hoses require different crimping techniques and pressures. Some tools are manually operated, while others are hydraulic or electric, providing more consistent pressure and requiring less physical effort from the user.

The Process of Crimping Hose Fittings

1. Preparation Begin by cutting the hose to the required length using a hose cutter. Ensure that the cut is straight and clean to ensure a good seal.

'crimping tool for hose fittings - measuring wheel'

2. Insertion Insert the fitting into the end of the hose. Make sure it is pushed securely to the appropriate depth as specified by the fitting manufacturer.

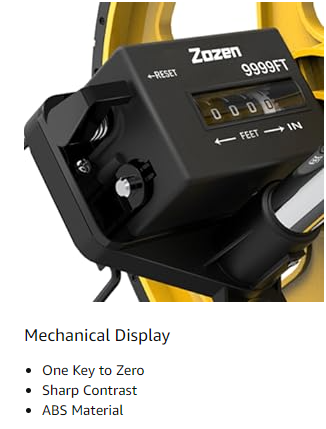

3. Measuring Before crimping, use a measuring wheel or caliper to check the depth of the fitting insertion. Consistency in measurement is vital for ensuring every fitting is crimped to the same specifications.

4. Crimping Position the hose and fitting in the crimping tool, aligning them properly. Apply the crimping mechanism, whether manually or via hydraulic means, until the tool reaches the required pressure. This may involve checking a pressure gauge to ensure the correct crimp has been achieved.

5. Inspection After crimping, visually inspect the joint for any defects. A well-crimped fitting will be uniform and should not show any signs of bulging or misalignment.

Benefits of Using Crimping Tools

The primary benefit of using crimping tools for hose fittings is the creation of a secure, robust connection that can withstand high pressures. Properly crimped fittings reduce the likelihood of hose failure due to leaks, thereby enhancing the safety and efficiency of any operation relying on these components. Additionally, the use of a crimping tool can improve the overall durability and lifespan of hoses and fittings, offering long-term cost savings.

In conclusion, crimping tools are indispensable for anyone working with hose fittings. Whether in automotive repairs, construction, or industrial applications, understanding how to effectively use these tools can lead to safer and more reliable outcomes. Always ensure that you are using the right tool for the job and follow manufacturer guidelines for the best results.

Latest news

What Are Construction Tools and How Are They Used?

NewsJul.11,2025

Professional-Grade Duct Rodding Tools for Superior Cable Installation

NewsJul.11,2025

Enhancing Safety and Efficiency with Modern Hot Stick Solutions

NewsJul.11,2025

Empowering Cable Installation with Advanced Rodder Solutions

NewsJul.11,2025

Elevate Your Cable Installation Projects with Cable Pulling Tools

NewsJul.11,2025

Efficient Cable Handling Solutions: Cable Rollers for Sale

NewsJul.11,2025