- 1. Maak seker dat die kabeltrommelstaander stabiel geplaas is voordat u die draad lê.

- 2. Pas die posisie van die kabeltrommelkrik redelikerwys aan volgens die rigting van die kabel.

- 3. Trekkragtoerusting kan gebruik word om te help om die draad gladder uit te lê.

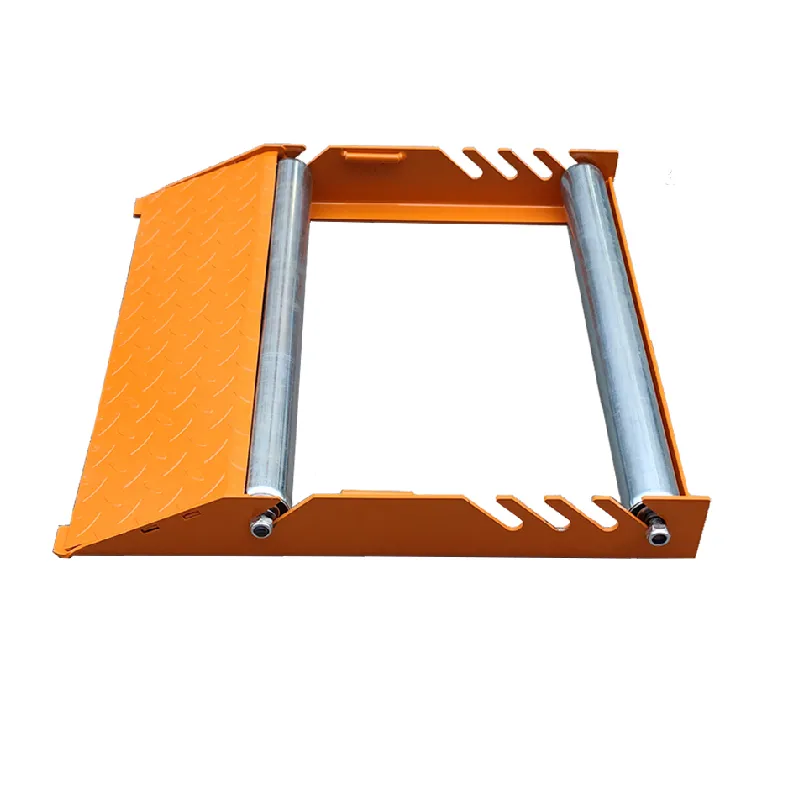

|

Geskikte kabeltrommel Dia |

300mm-700mm |

|

Geskikte kabeltrommel Maksimum breedte |

520mm |

|

Maksimum laaikapasiteit |

300 kg |

|

NW |

10.5 kg |

|

GW |

11.5 kg |

|

Grootte |

56*55*8cm |

|

Pakketgrootte |

59*58*10cm |

- 1. Stewig en stabiel: Gemaak van hoëgehalte-materiale, kan dit die gewig van die kabel weerstaan en die veiligheid en stabiliteit van die kabeluitbetalingsproses verseker.

- 2. Maklik om te beweeg: Die onderkant is gewoonlik toegerus met rollers om buigsame beweging op die konstruksieterrein te vergemaklik.

- 3. Sterk aanpasbaarheid: kan aanpas by verskillende tipes en spesifikasies van kabelleggingsbehoeftes.

- 4. Eenvoudige werking: redelike strukturele ontwerp, gerieflike en vinnige werking, wat werkdoeltreffendheid verbeter.

- 5. Die hoëgehalte- en funksionele ontwerp met uitgebreide tegnologie waarborg 'n lang lewensduur.

Cable Drum Roller Unwinder Maintenance Tips for Long-Term Performance

Proper maintenance of a Cable Drum Roller Unwinder is essential to ensure smooth operation, safety, and long-term performance. These devices play a critical role in efficiently handling and unwinding heavy cable drums on construction sites, factories, and utility projects. Regular upkeep not only prevents unexpected breakdowns but also extends the lifespan of both the roller and the cable drums it supports.

To begin, always inspect the roller assembly before each use. Check for signs of wear, rust, or deformation on the frame and rollers. Ensure that the bearings rotate smoothly without unusual noise or friction. Lubricate moving parts regularly using high-quality grease to reduce wear and maintain consistent rolling performance. Keep the roller shafts and drum supports clean and free from debris that could interfere with rotation.

In addition, verify that the locking mechanisms and adjustable arms are functioning correctly. Tighten any loose bolts and ensure that all components are securely fastened. If the equipment operates in harsh environments, such as outdoors or near moisture, apply anti-corrosion coatings to protect the metal surfaces.

Finally, store the Cable Drum Roller Unwinder in a dry and clean area when not in use. Avoid overloading the unit beyond its rated capacity to prevent structural damage. By following these simple yet effective maintenance practices, users can achieve reliable performance, reduce downtime, and ensure the safety of every cable installation project using their Cable Drum Roller Unwinder.

Top Benefits of Using a Cable Drum Roller Unwinder for Heavy-Duty Cable Installation

A Cable Drum Roller Unwinder is an essential tool for professionals working with heavy-duty cable installations. Designed to support and release large cable drums smoothly, this equipment significantly improves efficiency, safety, and precision on job sites. Its robust construction and user-friendly design make it a valuable asset for electrical contractors, telecom technicians, and industrial installers.

One of the key benefits of using a Cable Drum Roller Unwinder is enhanced work efficiency. By allowing the drum to rotate freely, it ensures smooth and controlled unwinding, minimizing cable twisting and tangling. This not only saves time but also reduces labor intensity during large-scale cable laying operations. Additionally, the stable frame design keeps the drum securely in place, preventing unwanted movement and ensuring a steady feed of cable.

Another major advantage is operator safety. Heavy cable drums can weigh hundreds of kilograms, and manual handling poses serious injury risks. The roller unwinder system eliminates the need for lifting or manual turning, allowing cables to be released safely and evenly.

Durability is also a strong point. Made from high-strength steel and equipped with heavy-duty rollers and bearings, the unit can withstand rough site conditions and repeated use. Its low-maintenance design ensures long-lasting performance even in demanding environments.

Overall, investing in a Cable Drum Roller Unwinder enhances productivity, ensures safer operations, and extends cable lifespan—making it an indispensable tool for any professional handling heavy-duty cable installation projects.

Efficient Cable Handling: How Cable Drum Roller Unwinders Improve Worksite Productivity

Efficient cable management is crucial in construction, electrical, and telecommunication projects where time and safety are top priorities. A Cable Drum Roller Unwinder is designed to simplify the process of handling and unwinding heavy cable drums, helping workers complete installations faster and with greater precision. By integrating this practical device into daily operations, teams can significantly improve worksite productivity and reduce unnecessary labor.

The main advantage of a Cable Drum Roller Unwinder lies in its ability to streamline cable deployment. Instead of manually rolling or lifting cable drums, the unwinder allows smooth, controlled rotation, enabling a steady feed of cable without tangling or strain. This reduces downtime caused by cable twists or damage, ensuring continuous workflow and minimizing material waste.

Moreover, the unwinder’s sturdy construction and adjustable design accommodate various drum sizes, making it versatile for different project needs. Workers can easily load and position cable drums, cutting setup time and enhancing operational efficiency. In addition, the use of high-quality bearings and rollers ensures effortless cable movement, even when dealing with heavy or long-length cables.

From a safety standpoint, the Cable Drum Roller Unwinder reduces the risk of workplace injuries by eliminating manual lifting and uncontrolled drum movement. This not only protects workers but also promotes a safer, more organized job site.

In conclusion, incorporating a Cable Drum Roller Unwinder into cable installation tasks leads to faster operations, improved cable quality, and better team performance—making it a smart investment for any professional seeking greater efficiency and productivity on site.